Projection screen and projection system

A technology of projection screen and cylindrical microlens, which is applied in the field of projection display, can solve the problems of uneven image intensity and uneven distribution of light intensity displayed on the projection screen, and achieve the effect of improving the uniform effect of display brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

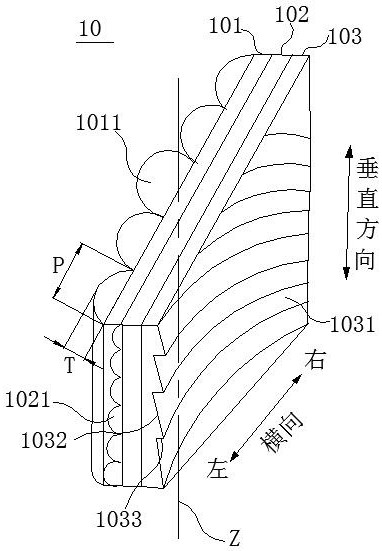

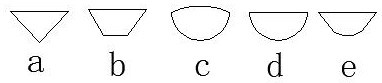

[0049] Such as figure 2 As shown, a projection screen includes a columnar microlens layer 101 arranged along the thickness direction of the projection screen, a first substrate layer 102 and a reflective microstructure layer 103, and the columnar microlens layer 101 is arranged on one side of the first substrate layer 102 side. Wherein, the columnar microlens layer 101 includes a columnar microlens layer I and a columnar microlens layer II, and the columnar microlens layer I includes a plurality of vertical columnar microlenses 1011, with the central axis Z as the reference, along the horizontal direction of the projection screen toward both ends. The aspect ratio of the set vertical columnar microlenses 1011 decreases gradually, and the central axis Z is the symmetry axis of the vertical columnar microlenses 1011 whose aspect ratio is the maximum in the columnar microlens layer I; the columnar microlens layer II includes several transverse The columnar microlenses 1021 , th...

Embodiment 2

[0082] On the basis of Example 1, as Figure 10 As shown, diffusing particles and / or light-absorbing materials are arranged on the columnar microlens layer.

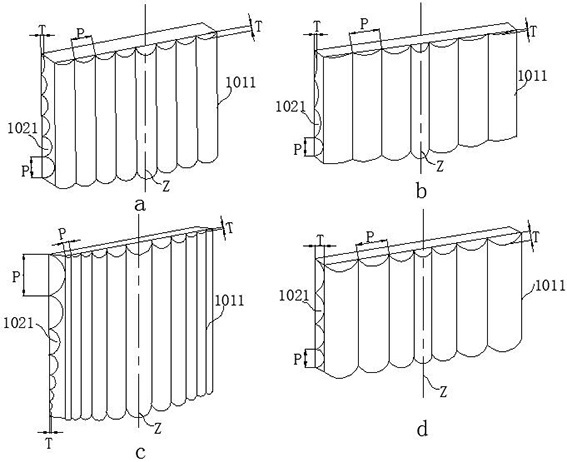

[0083] Such as Figure 10 As shown in a, the columnar microlens layer includes a columnar microlens layer I composed of several vertical columnar microlenses 1011 and a columnar microlens layer II composed of several horizontal columnar microlenses 1021, wherein the vertical columnar microlenses 1011 and the horizontal columnar microlenses Diffusion particles 1034 are arranged in the microlenses 1021, and these diffusion particles 1034 can uniformly scatter the light passing through the columnar microlens layer, further making the light intensity distribution more uniform. Diffusion particles 1034 include but are not limited to silicon dioxide particles, aluminum oxide particles, titanium oxide particles, cerium oxide particles, zirconium oxide particles, tantalum oxide particles, zinc oxide particles, magnesium fluorid...

Embodiment 3

[0091] The difference between this embodiment and the projection screen of Embodiment 1 is that: refer to Figure 11 As shown in the schematic diagram of the structure of the projection screen, the surface of the columnar microlens layer 101 away from the first substrate layer 102 is a rough surface 1012, and the rough surface 1012 is in the vertical direction of the columnar microlens layer 101. The cylindrical surface of the cylindrical microlens 1011 is formed by roughening. Here, the rough surface 1012 may be formed by sandblasting or surface roughening of the mold, followed by transfer printing with glue or spraying glue with diffused particles. The rough surface 1012 can further diffuse the light, and play the role of uniform light, hardening protection and imaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com