Self-centering device of thick-film resistor disc for automatic feeding and discharging of laser resistor trimming machine

A technology of automatic loading and unloading and thick film resistors, which is applied in the direction of resistors, resistor manufacturing, circuits, etc., can solve problems such as increased friction coefficient, easy to push, and sheet deformation, so as to improve precision, improve accuracy, The effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

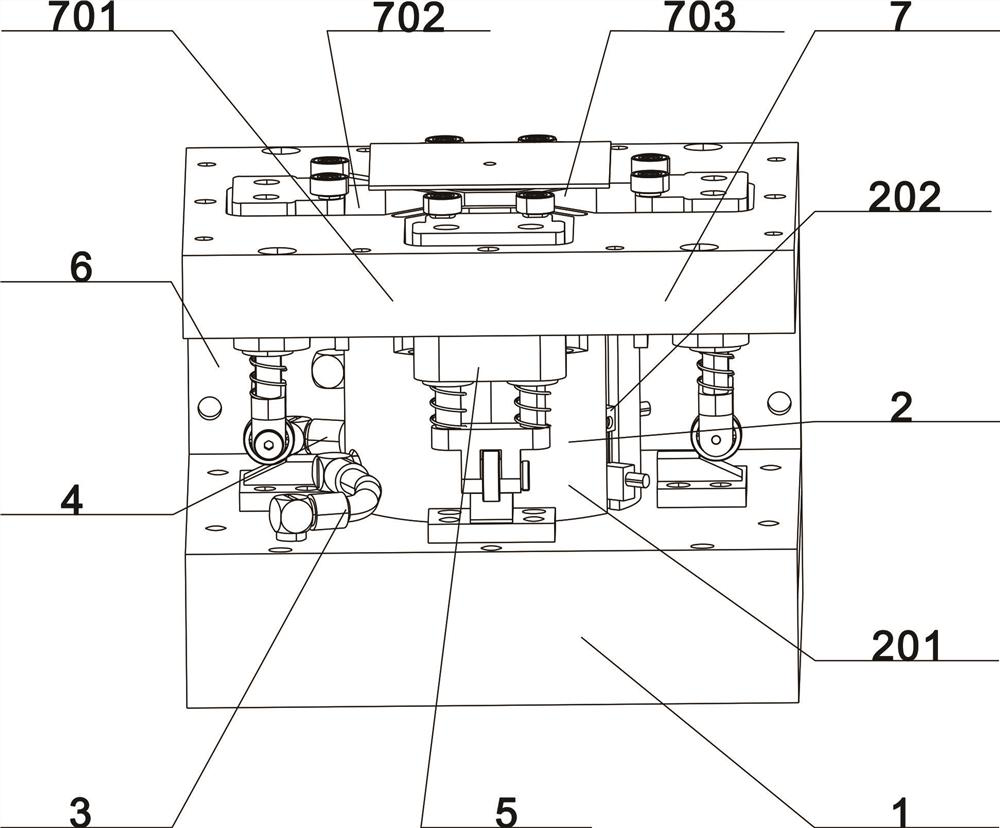

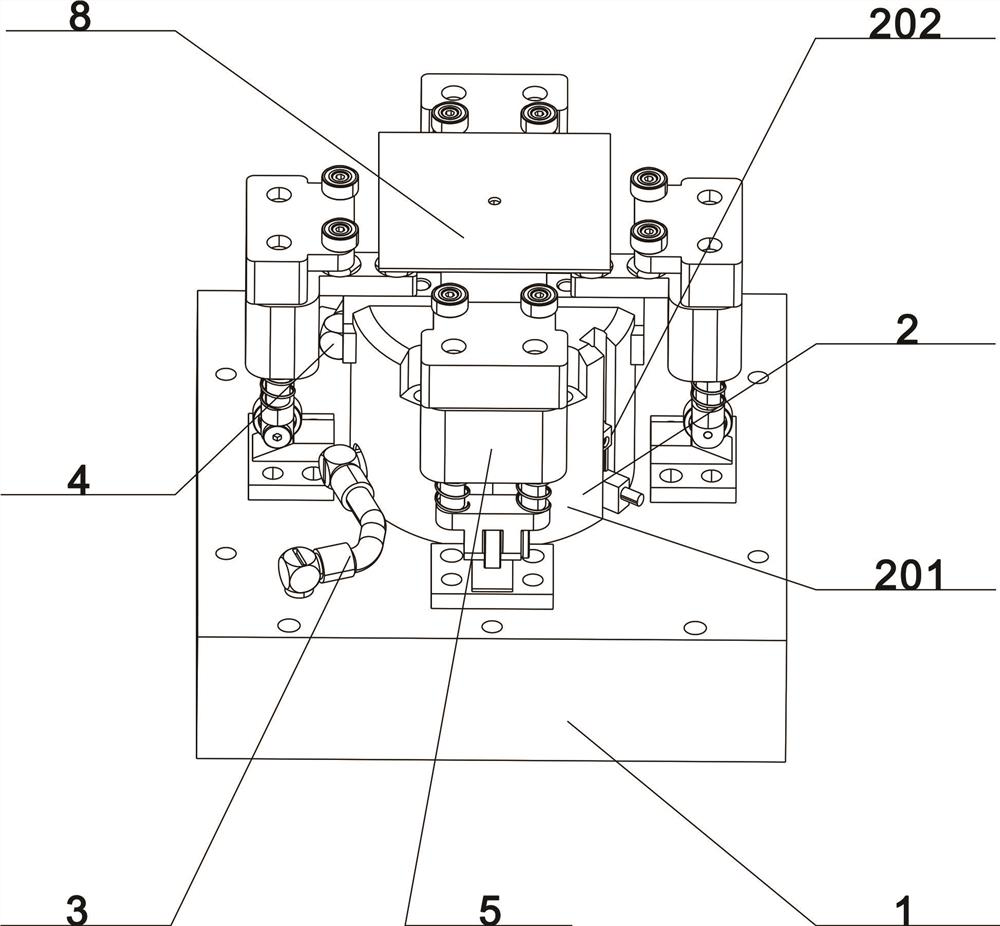

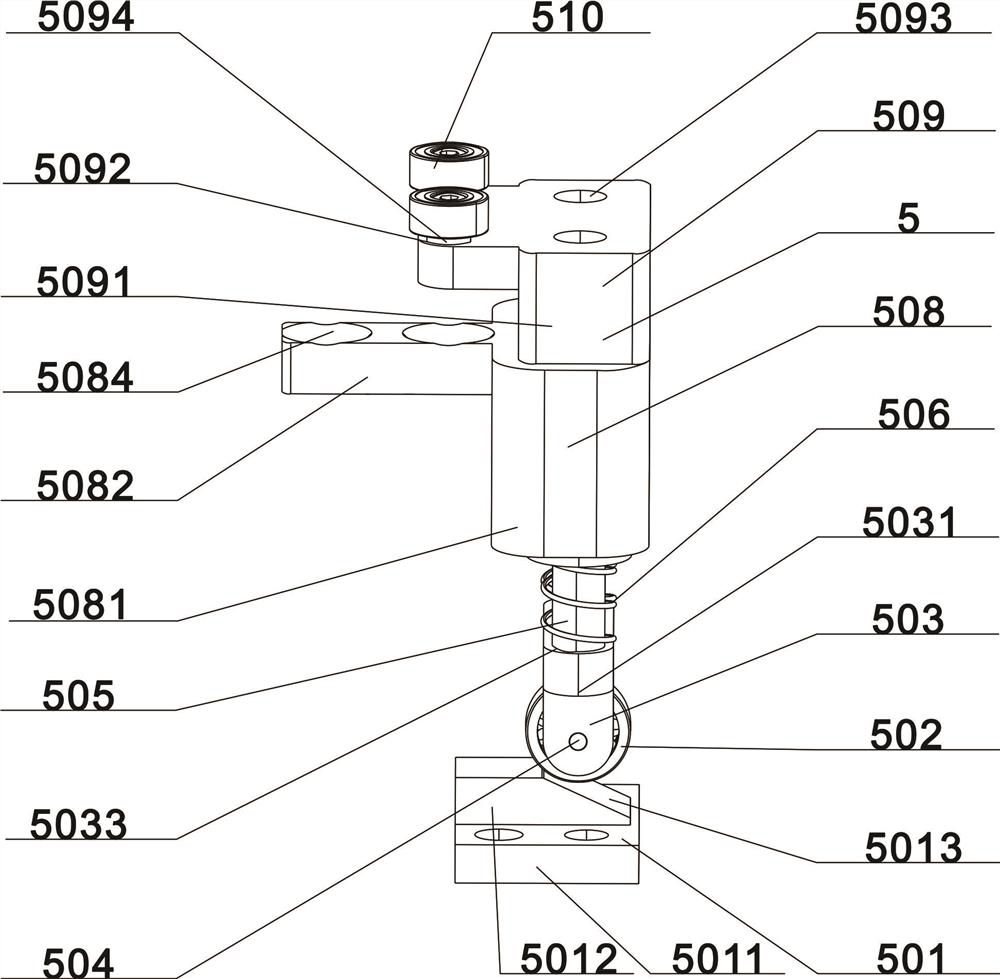

[0032] As shown in the figure, a self-centering device for thick film resistors used for automatic loading and unloading of a laser resistance adjustment machine, including a base plate 1, a four-catch cylinder 2, an air intake pipe 3, and an air outlet pipe 4; the middle position of the base plate 1 is fixed A four-catch cylinder 2 is provided, and the four-catch cylinder 2 is fixedly connected to the base plate 1; the air intake pipe 3 is fixedly arranged at the front left side of the four-catch cylinder 2, and the air outlet pipe 4 is fixedly arranged behind the left side of the four-catch cylinder 2 In the central position, the intake pipe 3 and the outlet pipe 4 are fixedly connected with the four-catch cylinder 2; Automatic centering and positioning of thick film resistors; the side connecting plate 6 is fixedly ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com