Lead-acid storage battery charging circuit and charging method

A technology for lead-acid batteries and charging circuits, applied in battery circuit devices, battery/fuel cell control devices, circuit devices, etc., can solve the problems of unrecognizable 60V and 72V voltages, low accuracy and reliability, and improve the use of Life and charging efficiency, accuracy and reliability are good, and the effect of simplifying the charging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

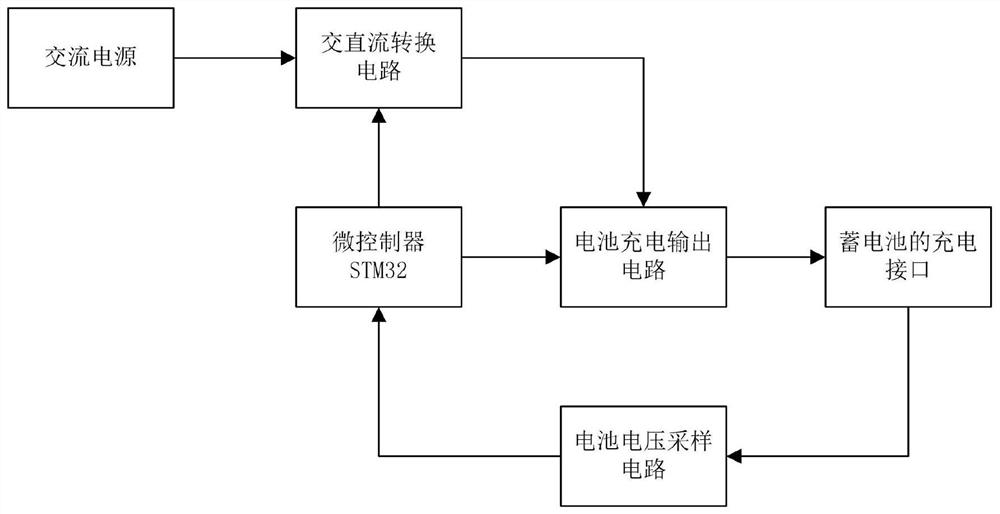

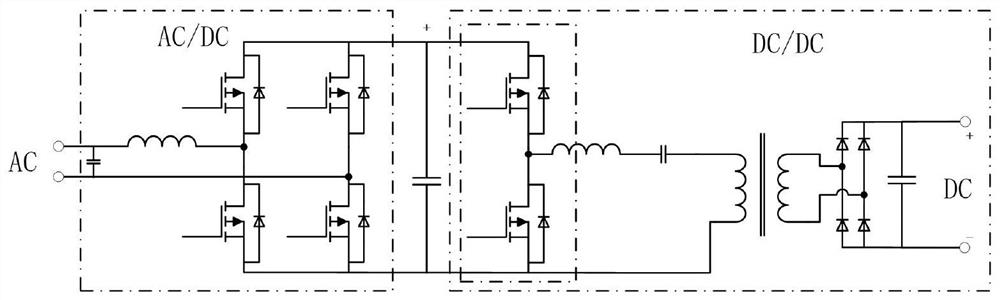

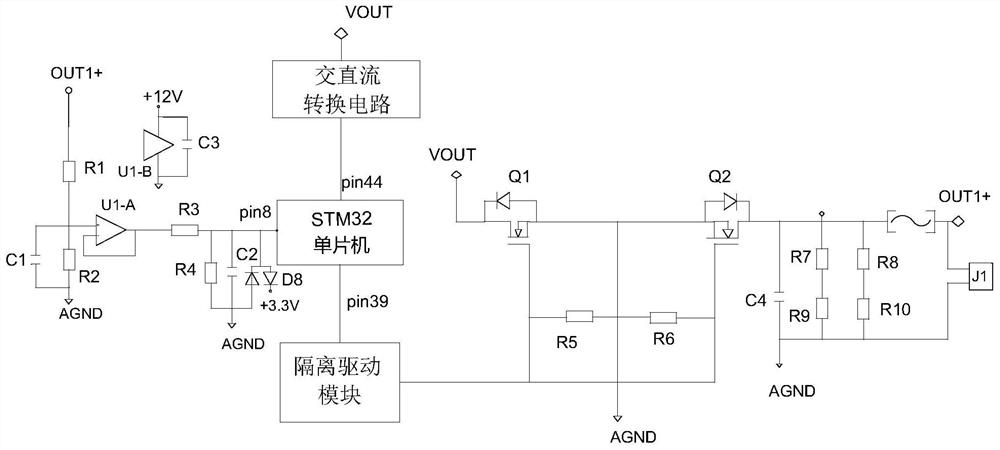

[0030] The lead-acid storage battery charging circuit of the embodiment of the present invention is as Figure 1 to Figure 4 As shown, it includes a battery voltage sampling circuit, a battery charging output circuit, an AC-DC conversion circuit and a control circuit. The input terminal of the AC-DC conversion circuit is connected to the AC power supply, and the output terminal is connected to the battery charging output circuit. The output terminal of the battery charging output circuit and the sampling terminal of the battery voltage sampling circuit are respectively connected to the charging interface J1 of the lead-acid battery, the control circuit includes a microcontroller (STM32), and the output terminal of the battery voltage sampling circuit is connected to the battery voltage of the microcontroller The sampling signal input terminal, the control terminal of the AC-DC conversion circuit and the control terminal of the battery charging output circuit are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com