Embedded permanent magnet variable-frequency motor rotor

A variable frequency motor, built-in technology, applied in the direction of magnetic circuit rotating parts, electromagnetic field shielding, magnetic circuit shape/style/structure, etc., can solve the problems of increased rotor wear, rotor dynamic balance failure, difficult assembly, etc., to achieve The effect of reducing magnetic field loss, reducing manufacturing difficulty, and speeding up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

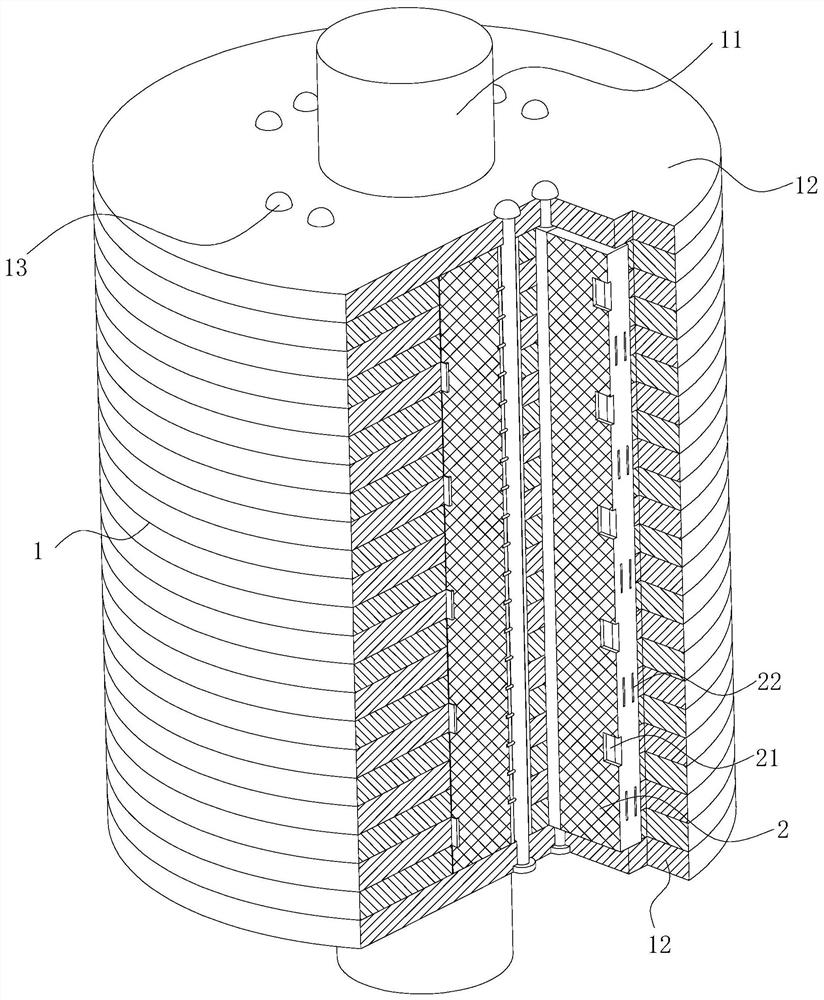

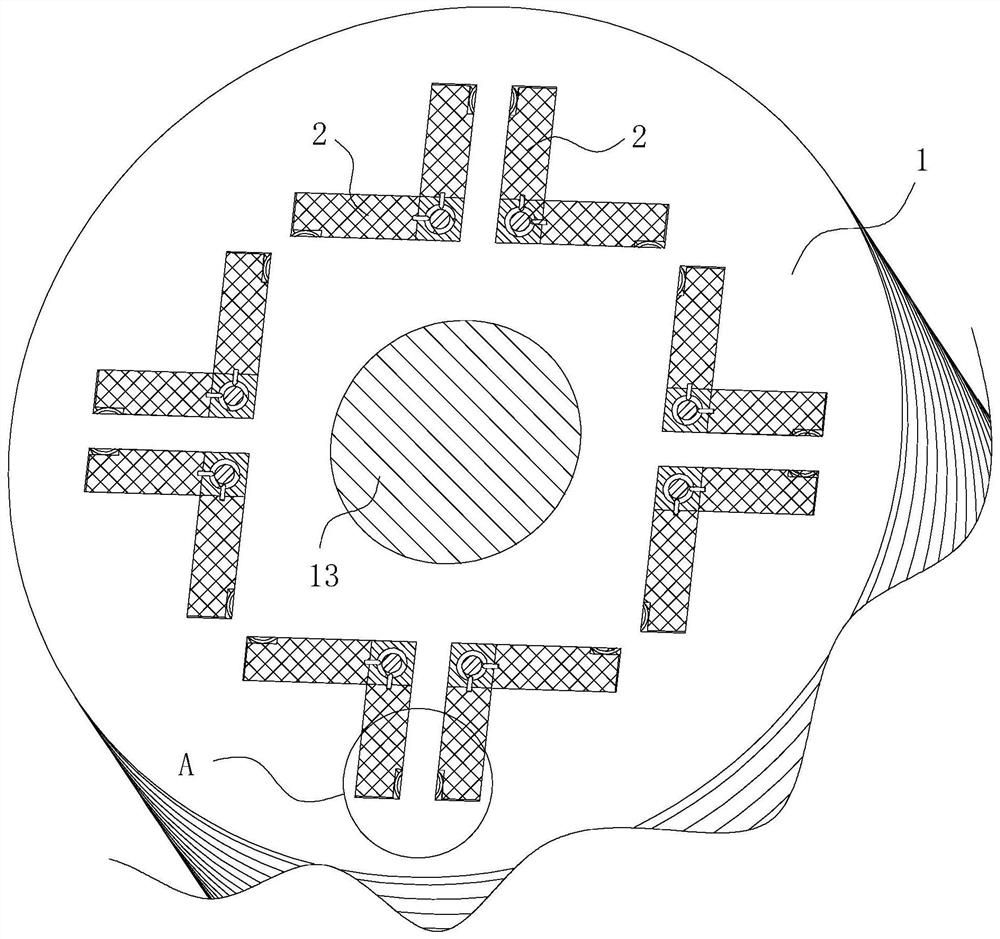

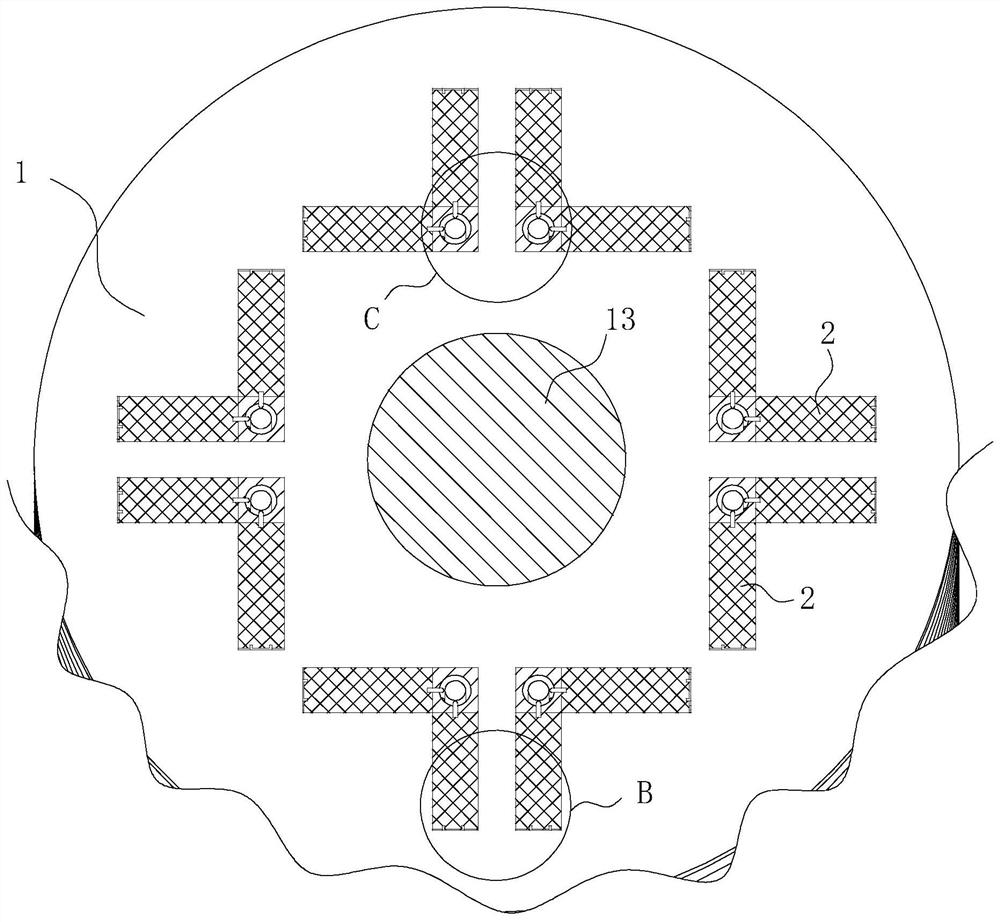

[0035] As an embodiment of the present invention, the main body 1 is obtained by stacking and fixing laminations on the rotating shaft 11; the laminations include the first lamination 23, the second lamination 24 and the third lamination 25; the main body The first lamination 23 in 1 is separated from the second lamination 24 by the third lamination 25; the lamination is obtained by stamping a thin silicon steel sheet; the first lamination 23 is provided with radial grooves 26 and tangential grooves 27; the radial groove 26 and the tangential groove 27 on the No. 1 lamination 23 are provided with a reed 28 on the side wall; the No. 2 lamination 24 is provided with a radial groove 26 and a tangential groove 27; The radial groove 26 on the No. 2 lamination 24 and the side wall of the tangential groove 27 are provided with a card 29; the card 29 on the side wall of the radial groove 26 on the No. One end of the tangential groove 27; the card 29 on the side wall of the tangential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com