Nail clipper

A technology of nail clippers and nails, applied in the field of nail clippers, can solve problems such as difficult manufacturing, complex structure, and inconvenient use, and achieve the effects of reduced manufacturing costs, labor-saving use, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

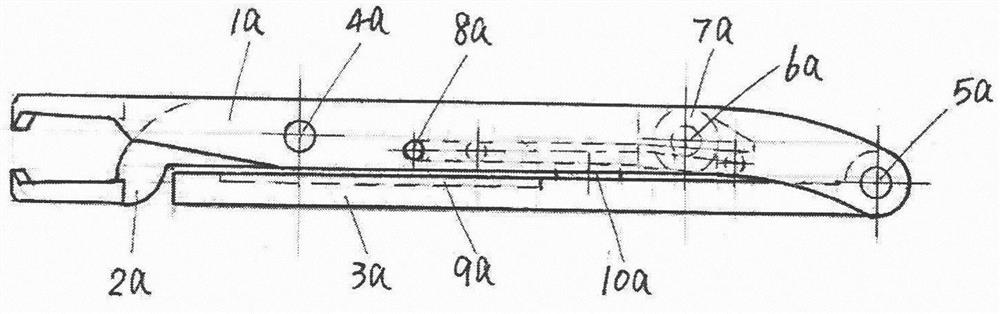

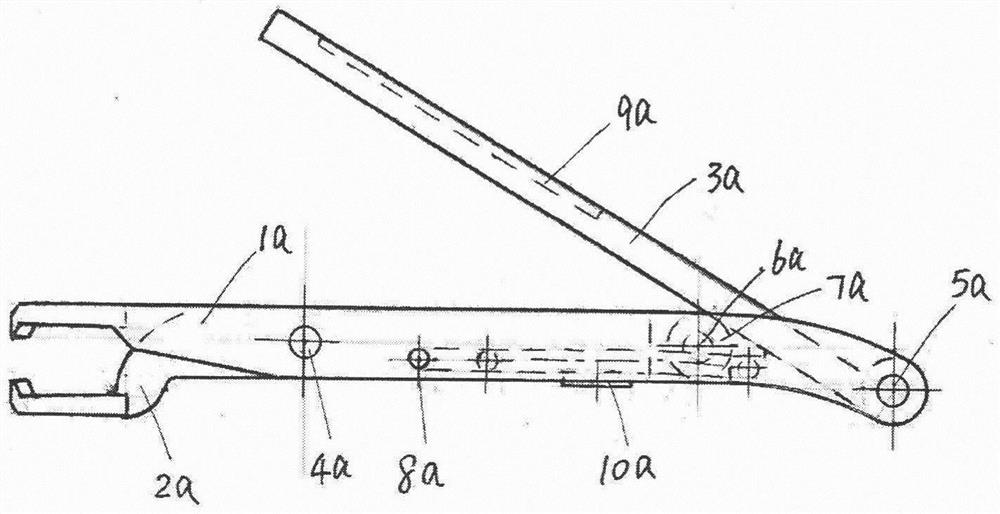

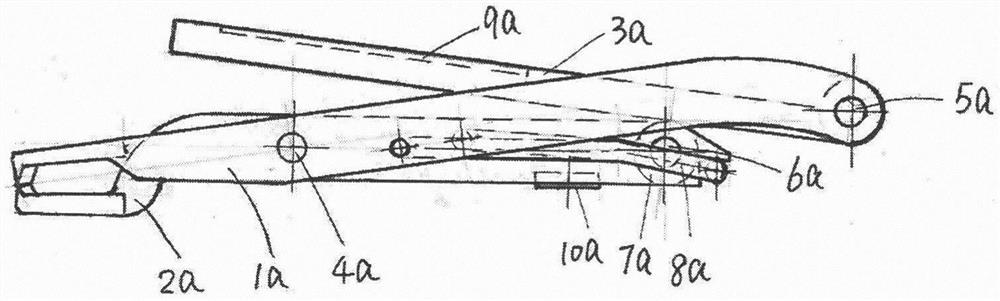

[0025] Embodiment 1: ultra-thin nail clippers, see Figure 1 to Figure 4 .

[0026] In order to reduce the amount of steel cut by ultra-thin nail clippers during metal processing, the upper jaw (1a) of the nail clipper is bent into a U-shape by section steel and then cold-forged to form the upper jaw, and the lower jaw (2a) is also made of The section steel is cold forged to form the lower jaw, and after drilling, the pin shaft (4a) is used to link the upper jaw (1a) and the lower jaw (2a), the pin shaft (5a) hinges the upper jaw (1a) and the lever (3a), and the roller (7a ) is installed on the rear end of the lower tong (2a) with a pin shaft (6a), the torsion spring (8a) is fixed in the upper tong (1a) by its own elastic force, and the tail end of the lower tong (2a) rests on the torsion spring (8a) On the crosspiece of the rear end, depress the torsion spring (8a) when trimming the nails, and utilize the elastic force of the torsion springs (8a) to reset after trimming the ...

Embodiment 2

[0027] Embodiment 2: universal type nail clipper, see Figure 5 to Figure 8 .

[0028] The general-purpose nail clipper of the present invention is made by sheet metal stamping. The upper tongs (1b) are placed on the lower tongs (2b), hinged with a pin (4b), and the positioning rod (11b) determines the opening of the jaws. Roller (7b) is installed in the rear end of lower jaw (2b) with bearing pin (6b), and the rear end of upper jaw (1b) and the rear end of lever (3b) are hinged with bearing pin (5b). Spring (8b) is fixed by bearing pin (4b), and its elastic force makes jaws open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com