Dust falling device for constructional engineering

A dust suppression device and construction engineering technology, applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problem that water pipes cannot be moved at will, and achieve the effect of improving service life and dust reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

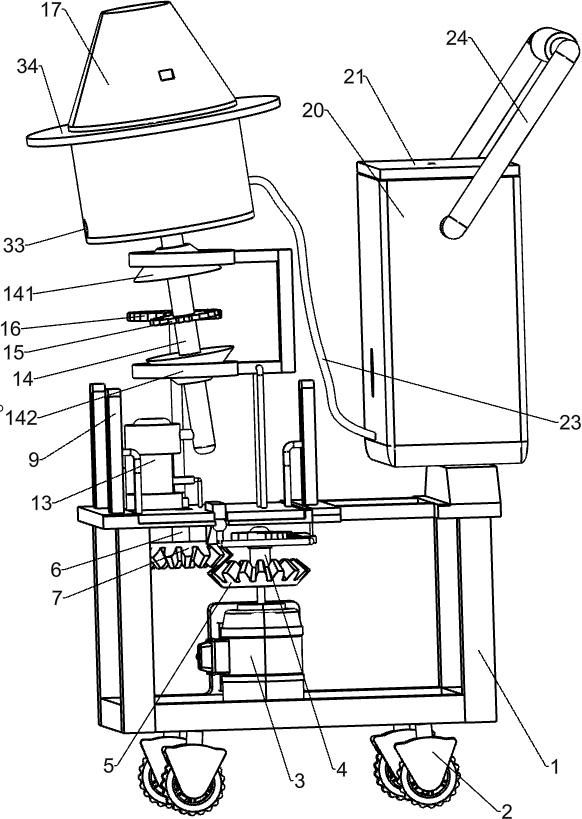

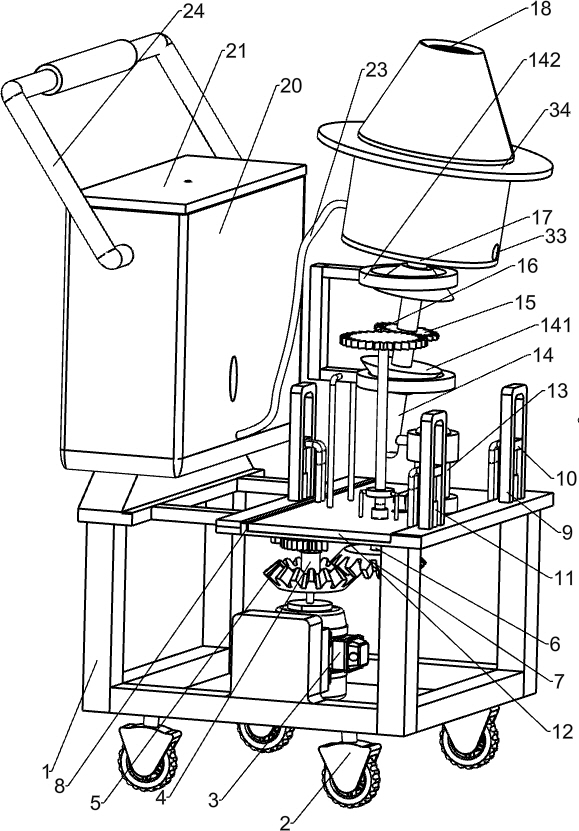

[0022] A dust suppression device for construction engineering, such as Figure 1-4 As shown, it includes a mounting frame 1, wheels 2, driving components, lifting components, rotating components, water spray components and pushing components. The mounting frame 1 is used to install the entire device. The bottom of the mounting frame 1 is provided with wheels 2. There is a driving component at the top, which is powered by a motor. There is a lifting component on the top of the installation frame 1, which can be lifted and lowered by sliding. The component is converted into water mist by inhaling a water source. The upper part of the installation frame 1 is provided with a pushing component, which is pushed by sliding, and the pushing component cooperates with the lifting component.

[0023] Such as figure 1 , 2 As shown in and 4, the drive assembly includes a reduction motor 3, the first rotating rod 4, the first bevel gear 5, the telescopic rod 6 and the second bevel gear 7,...

Embodiment 2

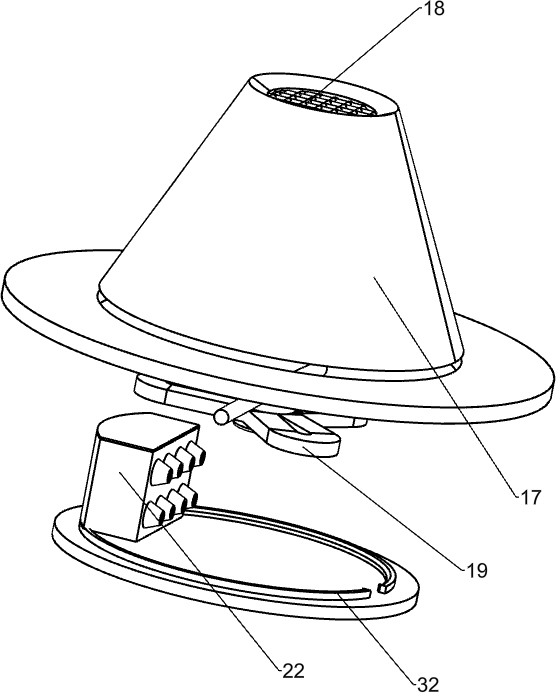

[0035] On the basis of above-mentioned embodiment 1, as Figure 1-3 As shown, it also includes an annular guide block 32, the inner bottom of the conical cylinder 17 is provided with an annular guide block 32, and there is a gap on the annular guide block 32, and a through hole 33 is provided at the bottom of the conical cylinder 17. The notch cooperates with the through hole 33 .

[0036] On the basis of Embodiment 1 above, a circular baffle 34 is also included, and the upper part of the conical cylinder 17 is provided with a circular baffle 34 .

[0037] The concrete operation process of above-mentioned embodiment: as Figure 1-3 As shown, when the conical cylinder 17 rotates, the ring guide block 32 is driven to rotate, and at the same time, the through hole 33 on the conical cylinder 17 is driven to rotate. The gap on the block 32 cooperates with the through hole 33, so that the water remaining in the conical cylinder 17 can be quickly cleaned and poured out.

[0038] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com