Ultrasonic cleaning machine

An ultrasonic and cleaning machine technology, applied in the mechanical field, can solve problems that have not been involved or only considered, and achieve the effects of improving work efficiency, rational design, and enhancing cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

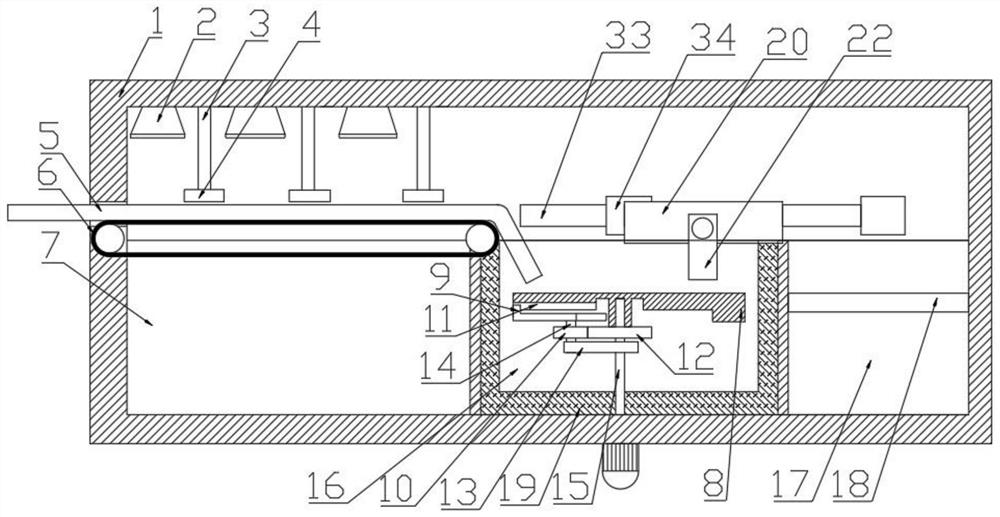

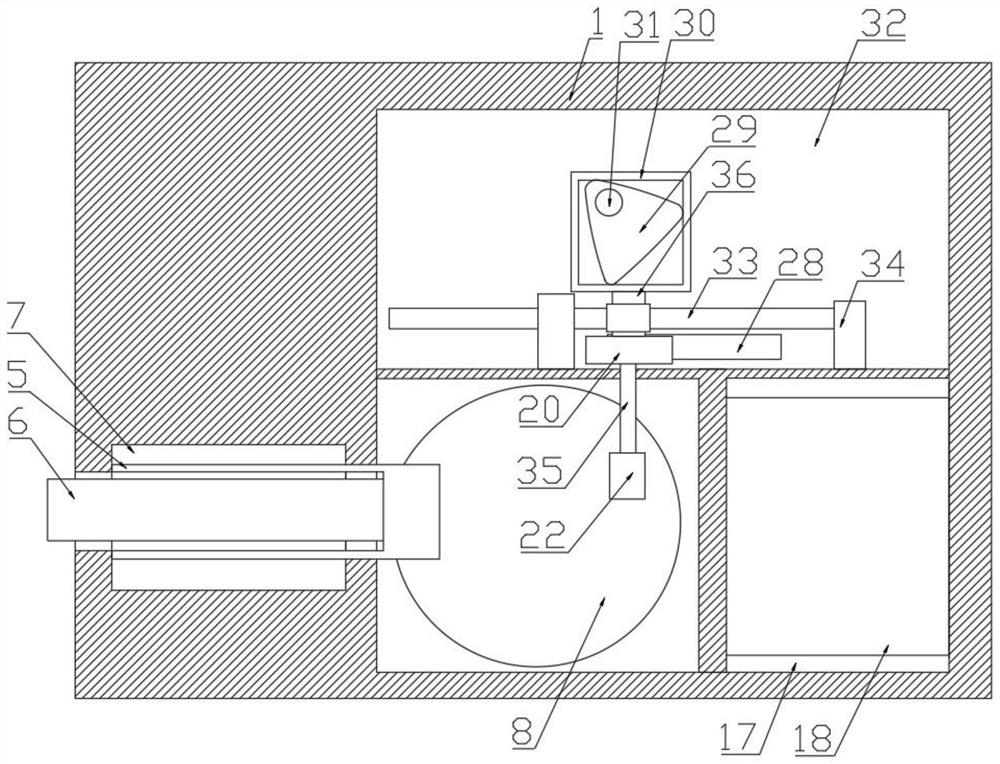

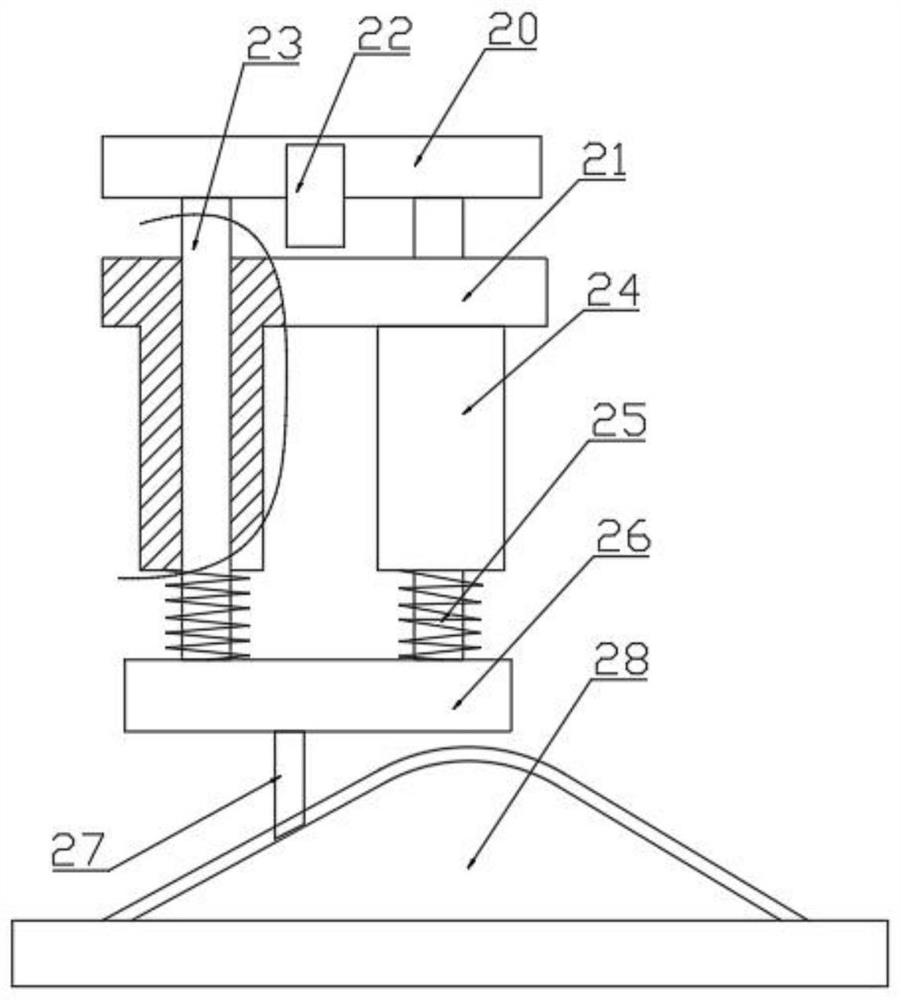

[0025] Example 1: Please refer to Figure 1~4 , in an embodiment of the present invention, an ultrasonic cleaning machine includes a base, an ultrasonic cleaning machine includes a box body 1, and a delivery chamber 7 is arranged on the left side inside the box body 1, and a conveyor belt 6 is arranged inside the delivery room 7 And the two sides of the conveyor belt 6 are fixedly provided with limiting plates 5, the lower end of the right side of the limiting plate 5 is placed on the upper side of the turntable 8, the upper side of the conveying chamber 7 is alternately provided with nozzles 2 and telescopic rods a3 and the lower side of the telescopic rods a3 is connected Hairbrush 4 is arranged, cleaning chamber 16 is arranged on the right side of conveying chamber 7 and ultrasonic transducer 19 is arranged on the inner wall of cleaning chamber 16, and turntable 8 is arranged inside cleaning chamber 16, and driving wheel 12 is arranged on the lower side of turntable 8 and dr...

Embodiment 2

[0027]Embodiment 2: The present invention also provides another embodiment, which is improved on the basis of the above embodiment. A drying chamber 17 is provided on the right side of the cleaning chamber 16 and inside the drying chamber 17 There is a placement plate 18, and the object clamped by the clamping part 22 moves upwards, crosses the cleaning chamber 16, and the object is transported to the drying chamber 17, and the moving rod 27 slides down from the arc-shaped plate 28, driving the lifting rod 23 to move downward, so that the object Place on the placement plate 18 of the drying chamber 17.

[0028] The working principle of the present invention: the object is transported to the conveying chamber 7 by the conveyor belt 6, and the nozzle 2 and the telescopic rod are activated at the same time to spray and scrub the object, so that the object is cleaned in the conveying chamber 7 for the first time, and the limit plate 5 Under guidance and transportation, the object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com