Rotary backward extrusion device for preparing ultra-fine grain pipe

A back-extrusion and ultra-fine-grain technology, applied in the direction of metal extrusion dies, etc., can solve the problems of complex devices and increased costs, and achieve the effects of convenient operation, low cost and large degree of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

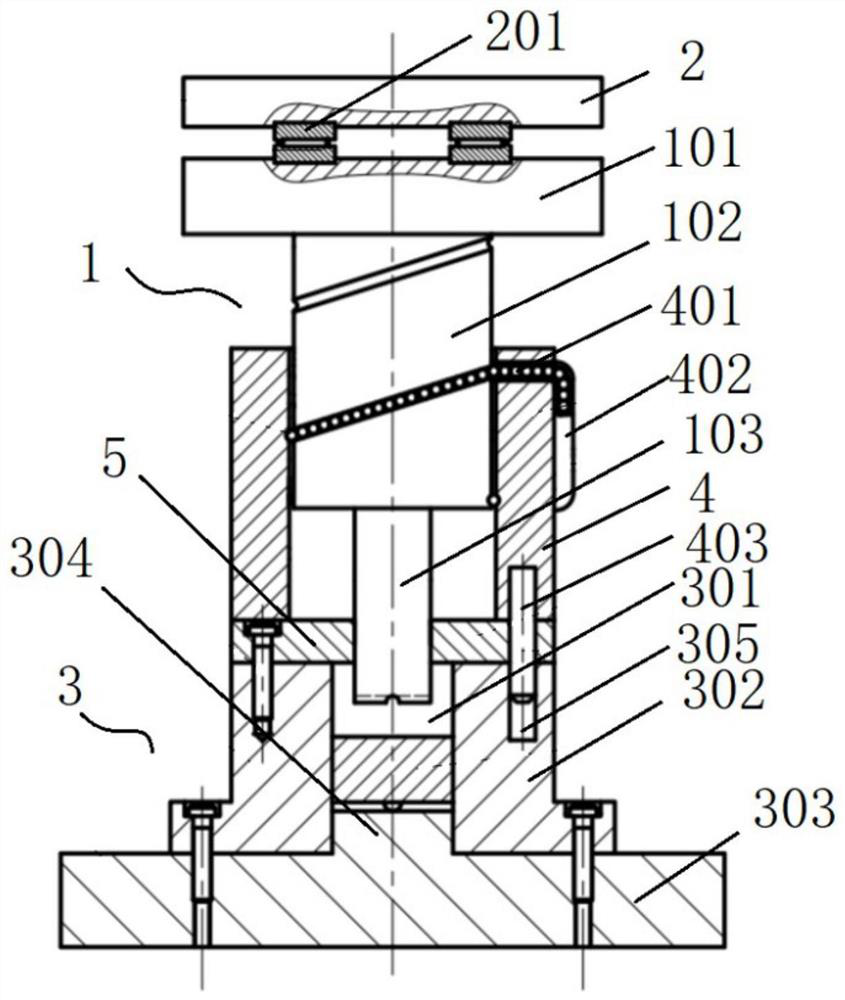

[0022] Such as figure 1 The rotary back-extrusion device for preparing ultra-fine crystal tube material includes:

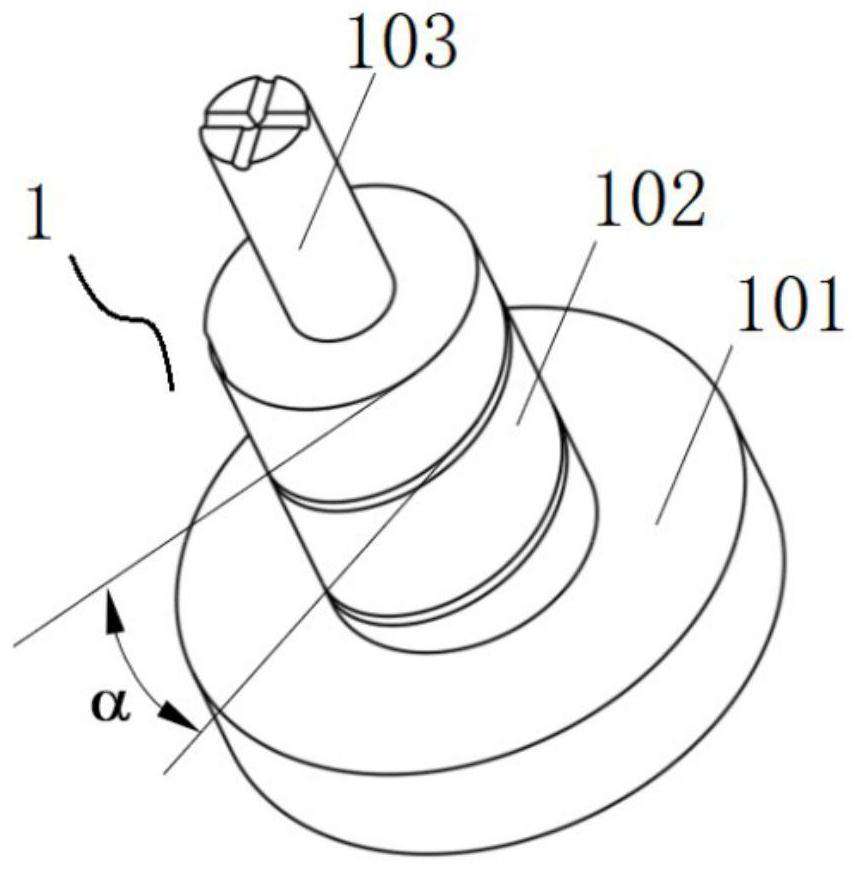

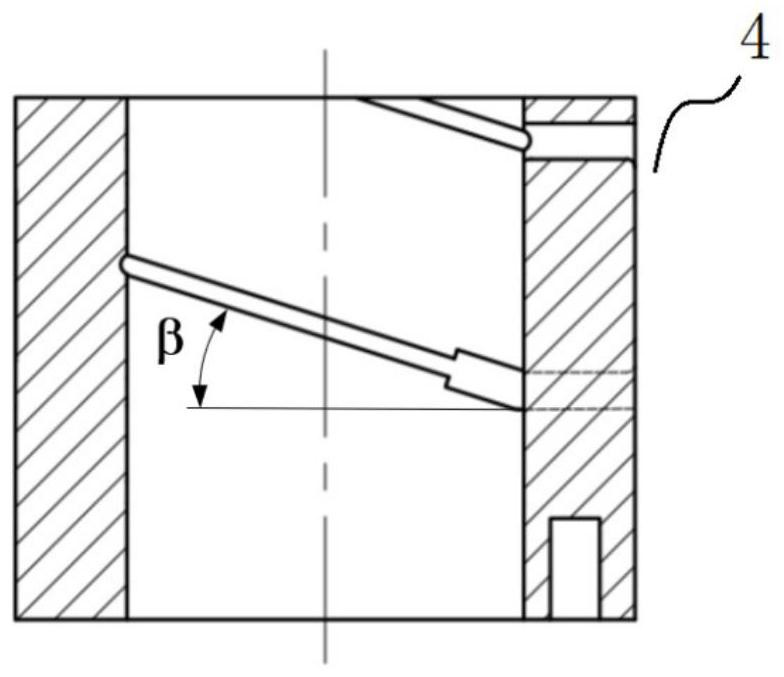

[0023] Such as figure 2 As shown in the extrusion punch 1, the extrusion punch 1 includes a bearing mounting block 101, a spiral groove column 102 and an extrusion column 103 spliced in sequence, and the bearing mounting block 101 is provided with an extrusion support plate 2, A bearing installation groove is provided on the opposite surface of the extrusion support plate 2 and the bearing installation block 101, and is connected by a horizontal bearing 201, and the extrusion punch 1 can rotate at a horizontal angle under the action of the horizontal bearing 201. The outer surface of the spiral groove column 102 is provided with a helical semicircular groove, and the helix angle is α. When the extrusion punc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com