Distributed blank-holding force generating device and control method for electro-permanent-magnet composite box-type stamping process

A generation device, electric permanent magnet technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of limited blank-holding force, increased equipment energy consumption, and failure to consider blank-holding force, etc., to achieve improved The ability to generate electromagnetic force, improve molding quality, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

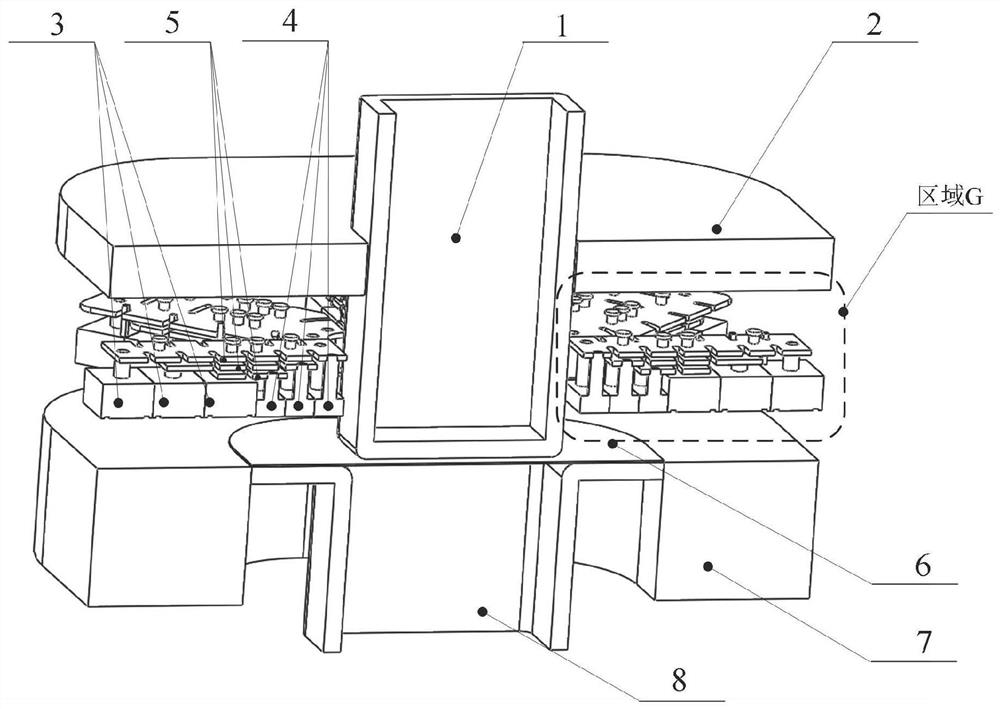

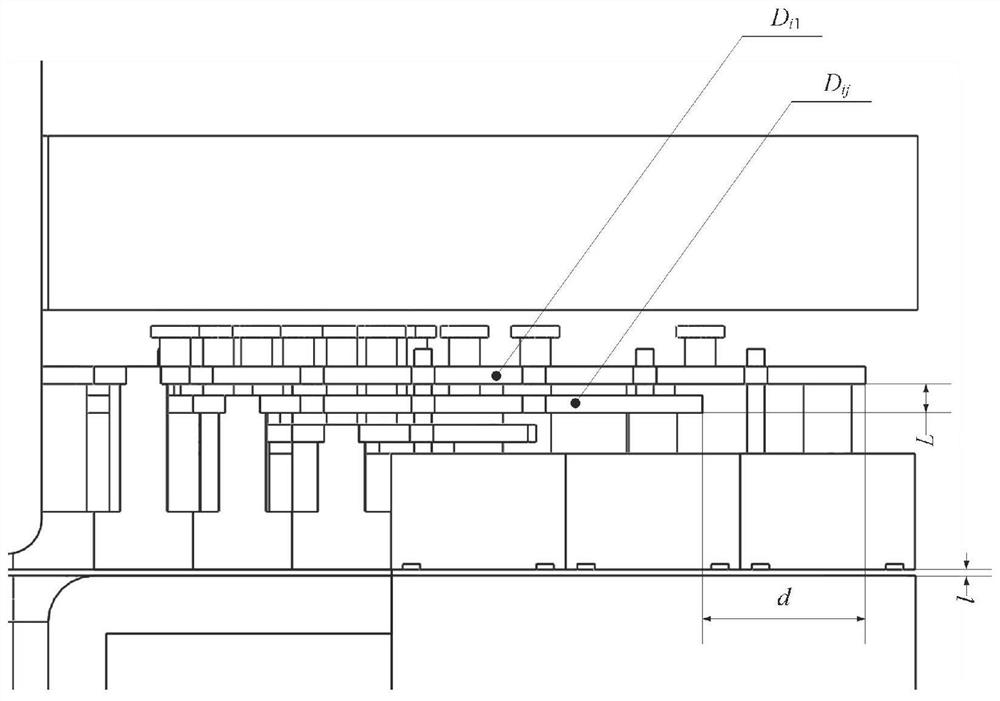

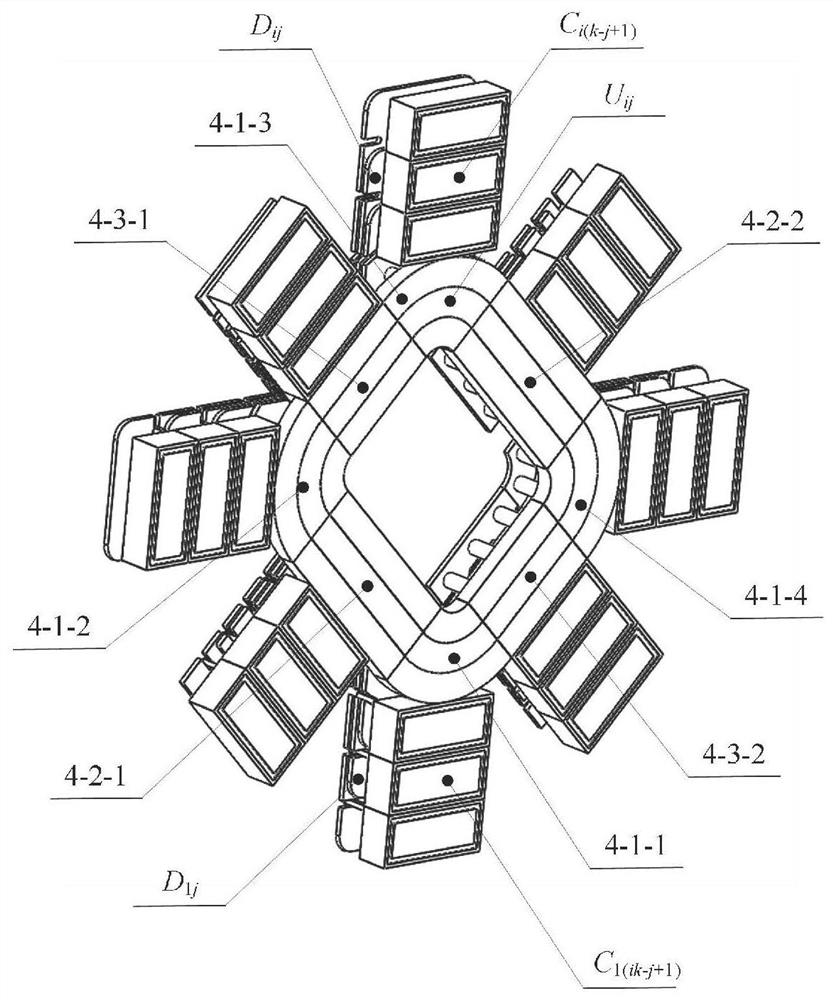

[0047] In this example, if figure 1 As shown, a distributed blank-holding force generating device and control method of a box-type stamping process of electro-permanent magnet composite is to place an electronically controlled permanent magnetic chuck 7 horizontally at the bottom, and the electronically controlled permanent magnetic chuck 7 is box-shaped. A box-shaped die 8 is provided; the upper surface of the die 8 is flush with the upper surface of the electric permanent magnet chuck 7, and the upper surface of the electric permanent magnet chuck 7 is a magnetic force generating surface, and on the upper surface of the die 8 A sheet material 6 is placed on it; just above the sheet material 6 is a blank holder 4; as Figure 4 As shown, the blank holder 4 is divided into 8 areas in the counterclockwise direction in the circumferential direction, including 4 rounded areas, 2 long-side areas and 2 short-side areas; wherein, the i-th area is along the radial direction and from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com