A non-ferrous metal powder high thermal insulation sintering device

A heat preservation sintering and non-ferrous metal technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of non-ferrous metal powders with many impurities, inability to guarantee heat preservation effect, and low sintering efficiency, so as to improve sintering quality, prevent oxidation, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

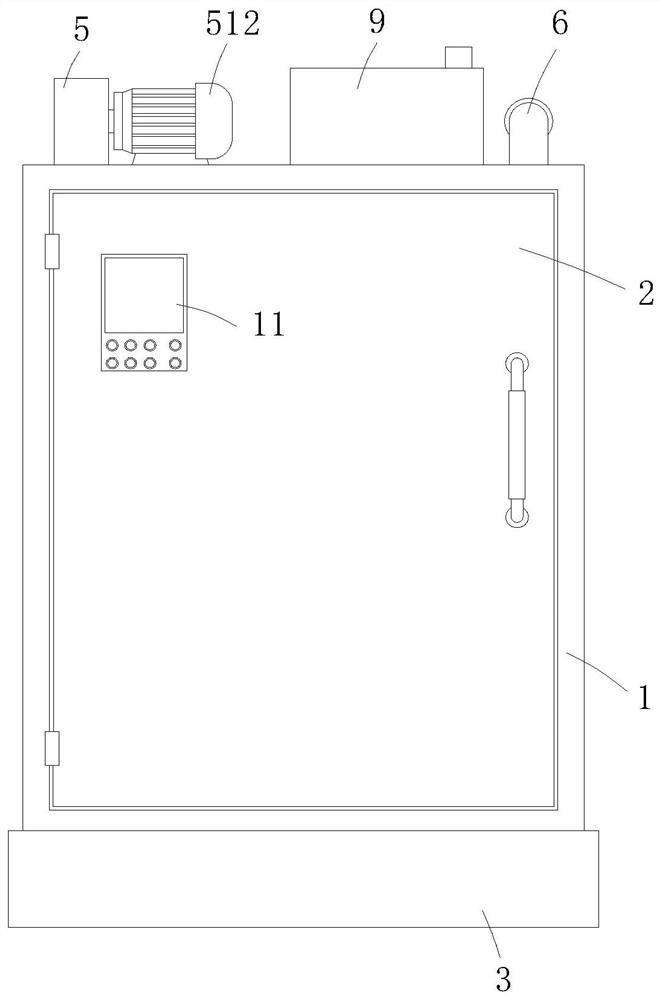

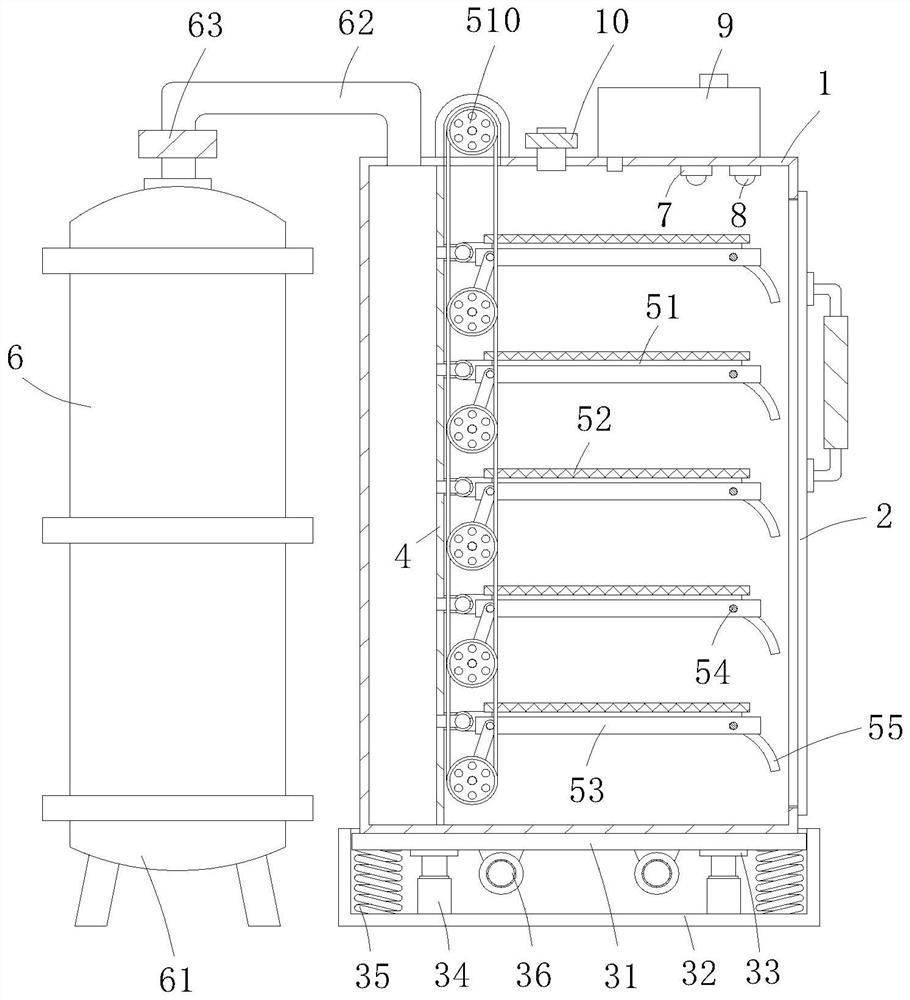

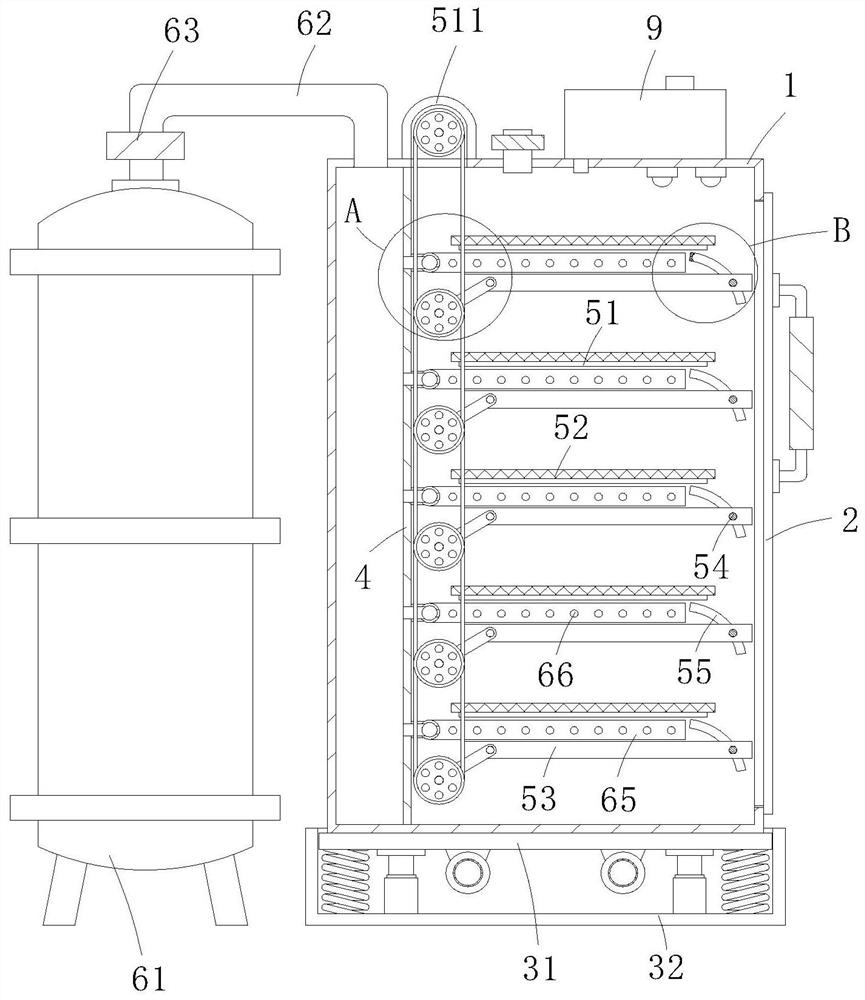

[0035] A non-ferrous metal powder high heat preservation sintering device, comprising a sintering box 1 and a box door 2 provided on the front side of the sintering box 1, the inside of the sintering box 1 is vertically provided with a partition 4, and the partition 4 will sinter The inner chamber of the box body 1 is divided into a sintering chamber located at the front side and a gas chamber located at the rear side. The inner chamber of the sintering chamber is provided with a sintering mechanism 5 and a cooling mechanism 6, which are used for high heat preservation sintering of non-ferrous metal powder, sintering A temperature sensor 7 is installed on the inner top wall of the cavity for real-time monitoring of the sintering temperature in the sintering cavity. A vacuum machine 9 is installed on the top wall of the sintering box 1, and the suction end of the vacuum machine 9 Extending into the sintering cavity to ensure the vacuum environment in the inner cavity of the sint...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that, as figure 2 and 3 As shown, the lower side of the sintering box 1 is provided with a powder vibrating mechanism 3 for uniform distribution of powder in the sintering box 1, the powder vibrating mechanism 3 includes a bottom plate 31 installed on the bottom wall of the sintering box 1, Base plate 31 is inserted in the inner cavity of base box 32, and the edge of the bottom wall of base plate 31 is connected with the inner bottom wall of base box 32 by a plurality of supporting springs 35, and the inner bottom wall of base box 32 is vertically installed with multiple A support cylinder 34, a support block 33 is installed on the telescopic end of the support cylinder 34, the support block 33 is in conflict with the bottom wall of the base plate 31, and two vibration motors 36 are symmetrically installed on the bottom wall of the base plate 31, in the bottom mold cavity 531 The non-ferrous metal powder that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com