Atmosphere bell furnace for ito target sintering

A bell jar furnace and atmosphere technology, applied in the field of industrial sintering furnaces, can solve the problems of difficult to improve product quality, not yet mastered the furnace manufacturing technology, difficult to guarantee after-sales service, etc., to achieve energy saving and consumption reduction equipment safety, Simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

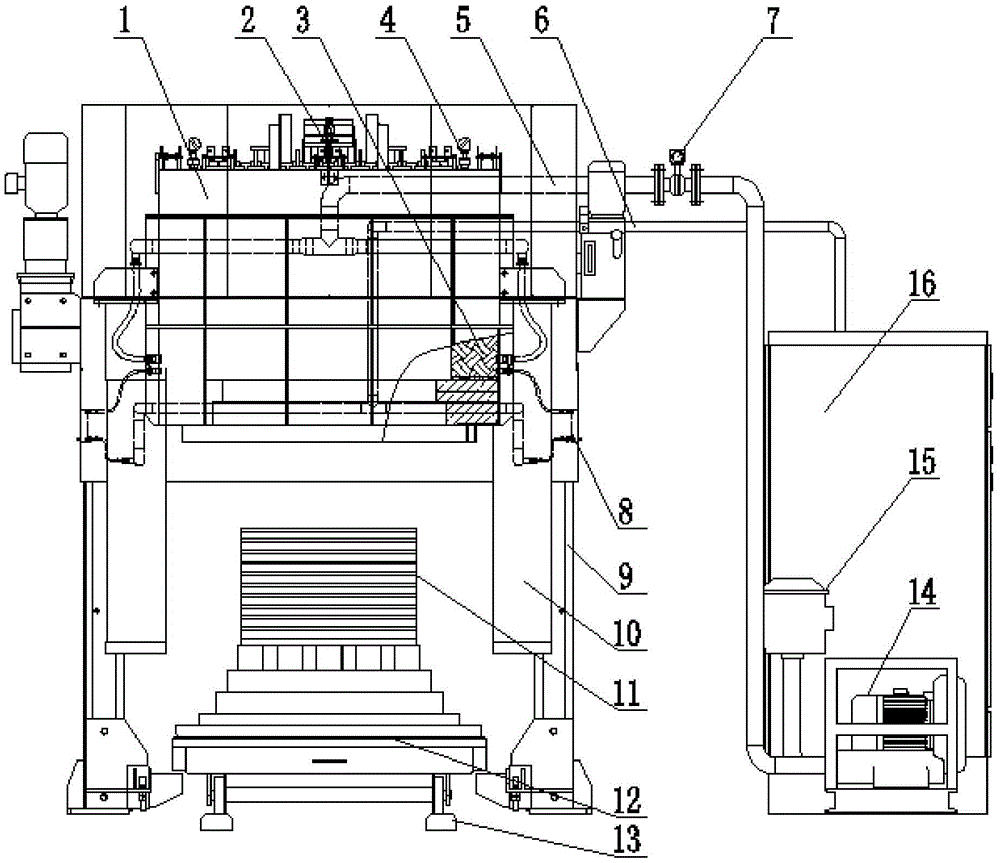

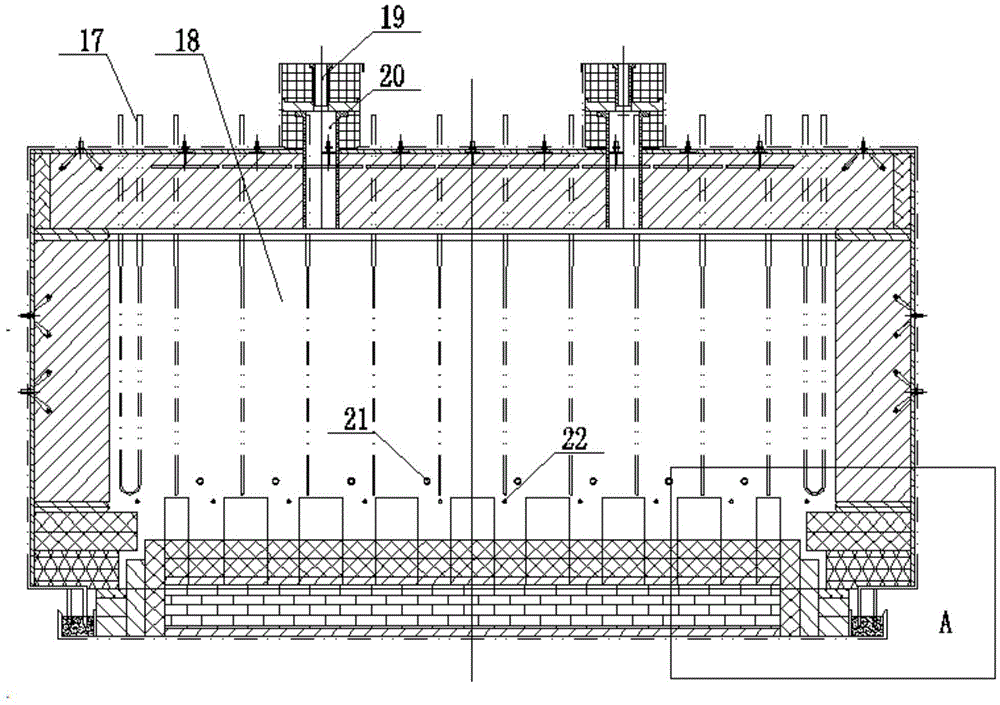

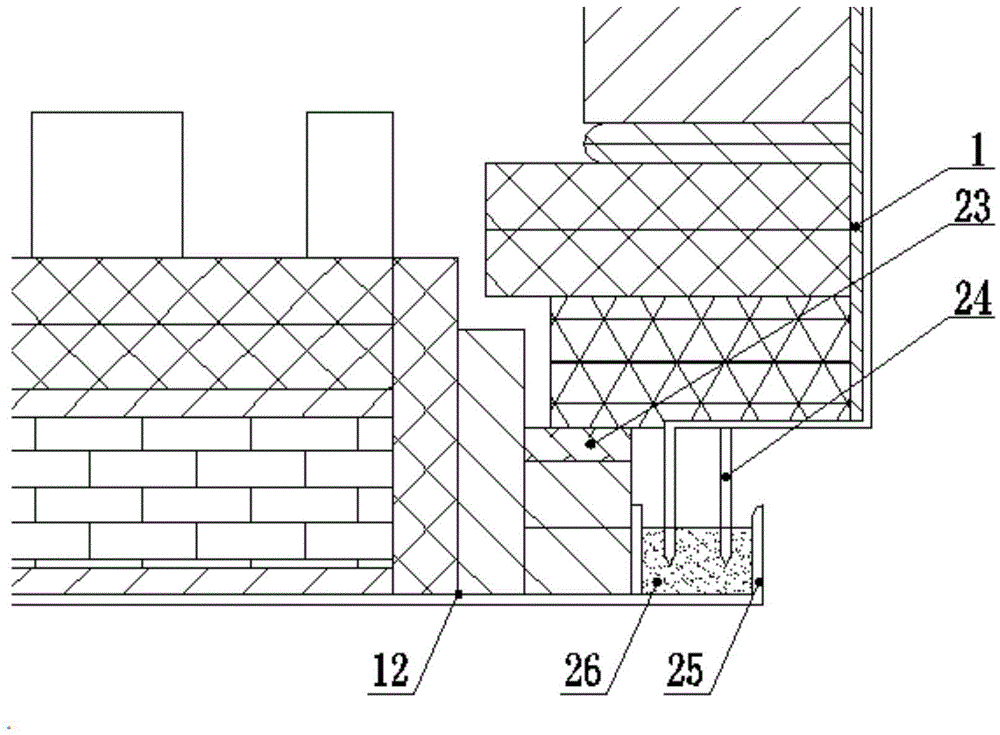

[0035] a kind of like figure 1 , figure 2 The shown atmosphere bell furnace for sintering ITO targets includes a furnace body 1, a furnace frame 9, a cooling pipeline 5, an atmosphere control and adjustment system 6 and a temperature control system. The furnace rack 9 is installed and positioned on the ground, and the furnace body 1 is installed above the furnace rack 9 and fixed by bolts so that the furnace rack 9 does not move in the horizontal direction.

[0036] Such as figure 1 , figure 2 As shown, the furnace body 1 is a rectangular columnar hollow structure installed on the furnace frame 9, mainly made of stainless steel plates spliced and welded, and the inner cavity is set as a furnace 18, and the top of the furnace 18 and the surrounding inner walls are provided with The high-temperature refractory material layer 3, the cooling air duct of the cooling system passes through the side wall at the bottom of the furnace body and leads to the furnace 18, and the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com