Heater structure of electronic powder firing furnace

A heater and sintering furnace technology, which is applied to electric furnace heating, lighting and heating equipment, furnaces, etc., can solve the problems of burning the heater, affecting the normal operation of the sintering furnace, and the heater failing to sinter electronic powder normally. To ensure the effect of sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

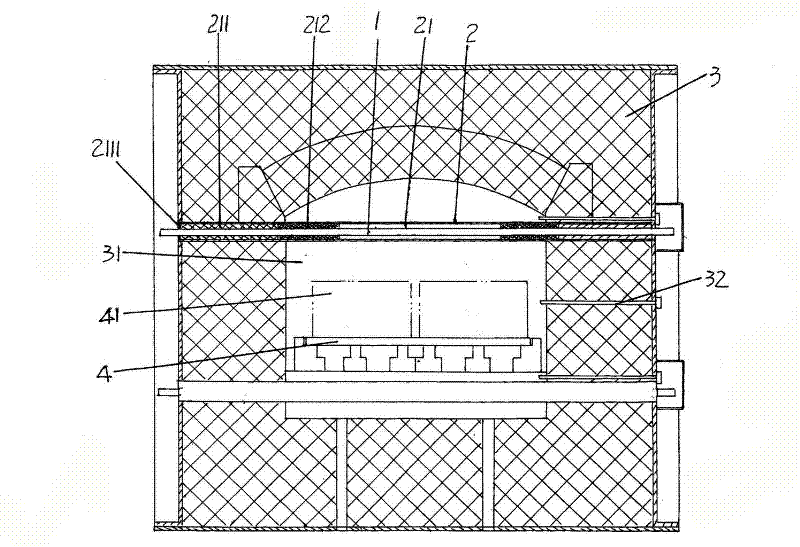

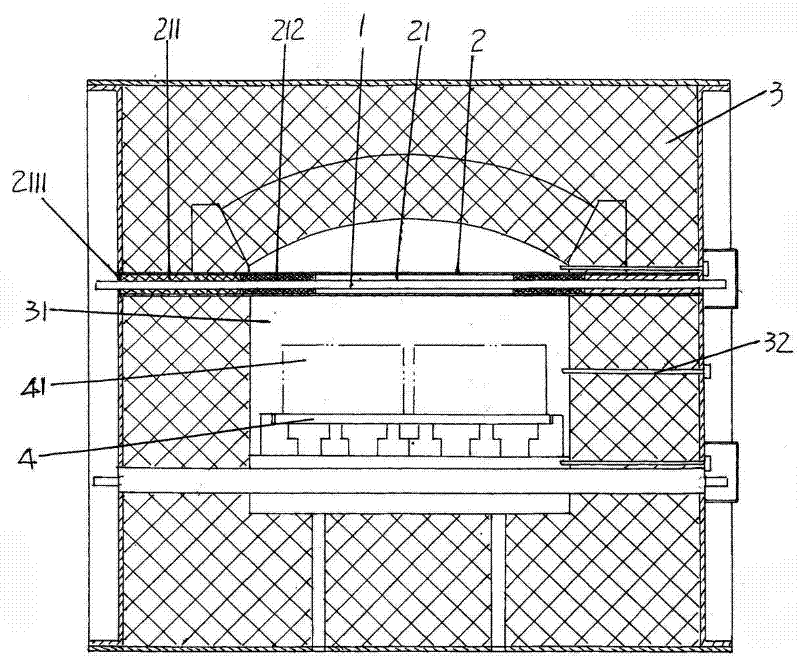

[0015] exist figure 1 In the above, the applicant shows the furnace body 3 of the electronic powder firing furnace. The furnace body 3 has a hearth 31. When in use, the electronic powder material 41 to be fired is carried on the setter 4 and the setter 4 is introduced into the furnace chamber 31, and thermocouples 32 for measuring the temperature in the furnace chamber 31 are arranged at intervals in the length direction of the furnace body 3.

[0016] The heater structure provided by the present invention is arranged at intervals along the length direction of the aforementioned furnace 31, the heater structure includes a heater body 1 and a protection tube 2, the middle part of the heater body 1 is located in the lumen 21 of the protection tube 2, and Both ends extend out of the tube cavity 21 and are fixed with the furnace body 1 shown in the figure. A first temperature-resistant spacer 211 and a second temperature-resistant spacer 212 are arranged in sequence at both ends ...

Embodiment 2

[0020] Only the heater body 1 uses a resistance wire rod, and the protective tube 2 is replaced with a quartz tube, and the rest are the same as the description of the first embodiment.

[0021] The heater structure obtained by the above-mentioned embodiments 1 and 2 has been tested by the applicant under confidentiality measures, and the results have shown that the technical effect described above by the applicant can be fully achieved, so it is an extreme technical solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com