Automatic feeding mechanism for pressing block milling plane machine tool

An automatic feeding and plane milling technology, which is applied to milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve problems such as low efficiency, low degree of automation, and high labor intensity, so as to improve feeding efficiency and automation degree , good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

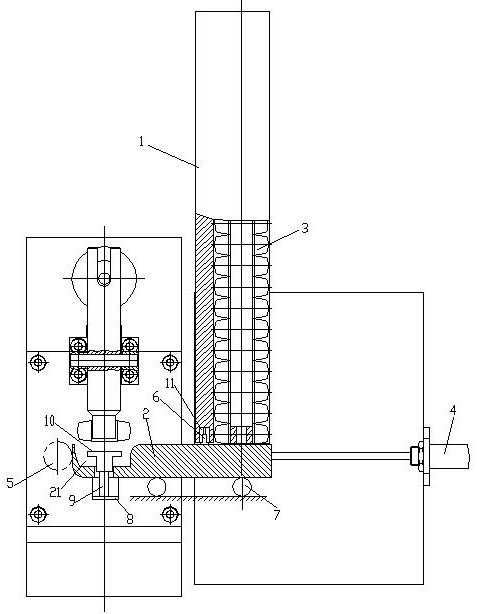

[0014] The automatic feeding mechanism of the briquette milling plane machine tool includes a storage tank 1, the bottom of the storage tank 1 is open, and the bottom of the storage tank 1 is provided with a feeding rod 2 that cooperates with the storage tank 1, and the feeding rod The upper plane of 2 cooperates with the bottom surface of the storage tank 1;

[0015] The content of the storage tank 1 is equipped with a workpiece 3, and the feed rod 2 is provided with a feed rod groove 21. When the workpiece 3 falls, it enters the feed rod groove 21, and a driving device 4 is provided to drive the feed rod. The rod 2 moves, so that the workpiece in the feeding rod groove 21 is transported to the machining position of the machine tool.

[0016] Further, the machine tool is provided with a block 5 that limits the position of the feeding rod 2 .

[0017] Further, the lower part of the storage tank 1 is provided with a blind hole 11, the blind hole 11 is provided with a telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com