Bamboo joint steel column, manufacturing process and auxiliary manufacturing device

A production process and technology of slub steel, applied in the direction of manufacturing tools, other manufacturing equipment/tools, columns, etc., can solve problems such as cracks at welds, and achieve the effect of improving quality and easy production quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

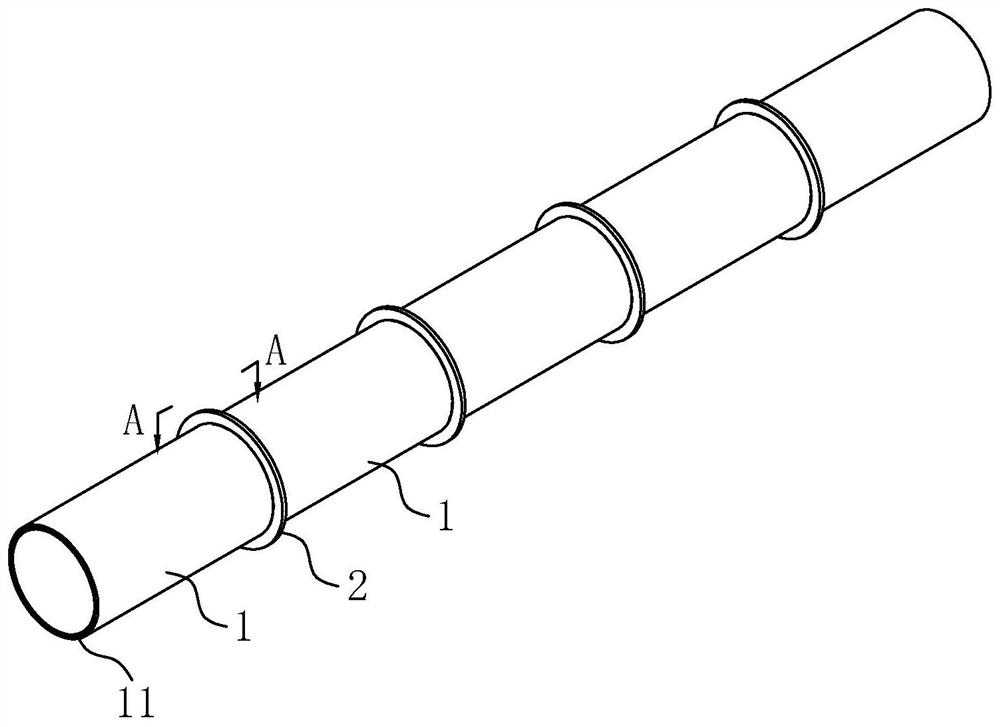

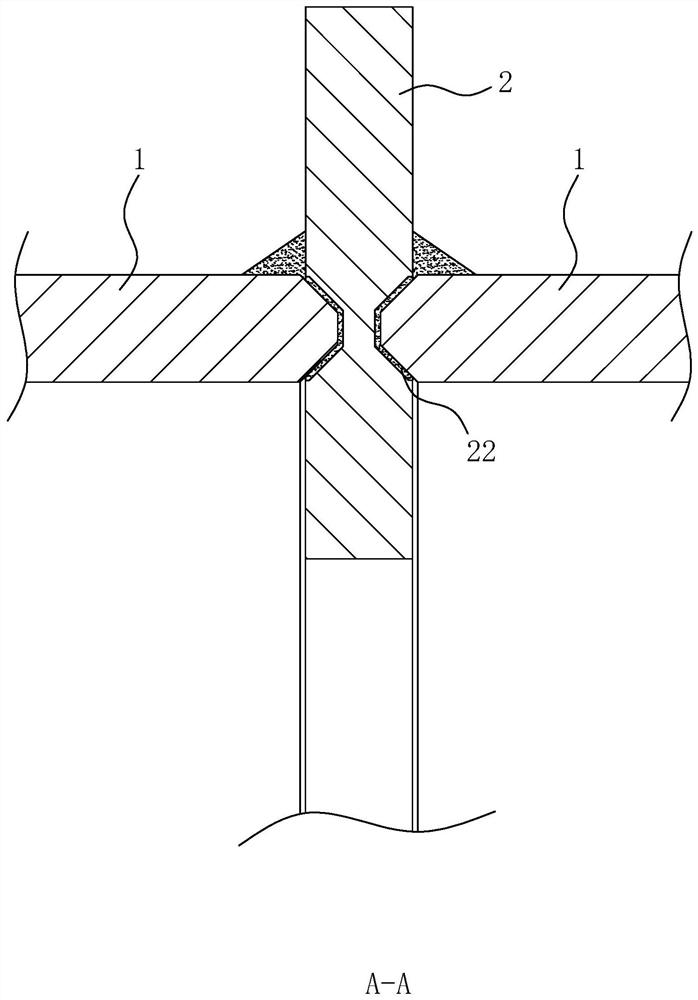

[0048] The embodiment of the present application discloses a bamboo-jointed steel column. refer to figure 1 The bamboo steel column includes a plurality of coaxially spliced round pipe units 1 and a first connecting plate 2 fixed at the joint of two adjacent round pipe units 1 . During manufacture, the first connecting plate 2 and the round pipe unit 1 are pre-welded and fixed, and then fully welded to reduce the possibility of cracks at the joints of two adjacent round pipe units 1 .

[0049] refer to figure 1 with figure 2 , The two ends of the outer wall of the round pipe unit 1 are provided with chamfers 11 along the circumferential direction. According to needs, the chamfer 11 can also be located at the ends of the inner wall and the outer wall of the round pipe unit 1 , so that the cross section of the end of the round pipe unit 1 is trapezoidal.

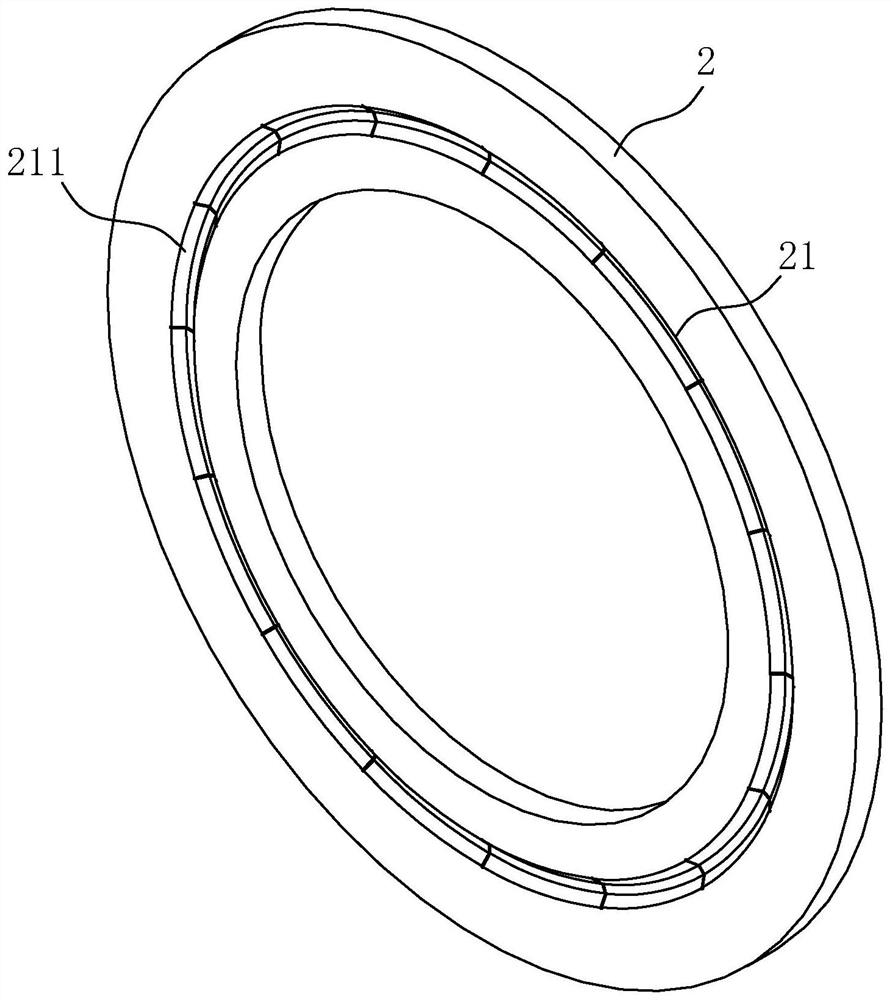

[0050] The first connecting plate 2 is a circular steel plate, and the two sides of the first connecting plate 2 are ...

Embodiment 2

[0061] The embodiment of the present application discloses a bamboo-jointed steel column. refer to Figure 4 with Figure 5 , the difference from Embodiment 1 is that the first connecting plate 2 is replaced by the second connecting plate 4, and the structure difference between the second connecting plate 4 and the first connecting plate 2 is; A slot 42 is opened on the side wall, and the bottom of the slot 42 is arc-shaped, which reduces the possibility of cracks forming along the slot 42 when the second connecting plate 4 is subjected to an external force. The slot 42 divides the end of the second connecting plate 4 into two symmetrically arranged flanges 41 , and the flanges 41 are provided with a plurality of fan-shaped openings along the circumferential direction. The flanges 41 on each side are bent away from each other to form a truncated cone-shaped shell. After bending, the fan-shaped opening is reduced, and the frequency of examination of two adjacent patents will ...

Embodiment 3

[0065] The embodiment of the present application discloses an auxiliary manufacturing device for a bamboo-jointed steel column. refer to Figure 8 with Figure 9 The auxiliary production device includes a linear guide rail 5 and two pressing mechanisms 6 mounted on the guide rail 5 that can approach and move away from each other. A plurality of support mechanisms 7 are installed between the two pressing mechanisms 6 on the guide rail 5 . Place the round tube unit 1 to be welded on the supporting mechanism 7 for support, place the second connecting plate 4 between two adjacent round tube units 1, and then press and tighten the plurality of round tube units 1 using the pressing mechanism 6 , and then perform pre-welding and full-welding operations.

[0066] refer to Figure 8 , the pressing mechanism 6 includes a support 61 that slides relative to the guide rail 5, and a drive rod 62 is threaded on the support 61 along the length direction of the guide rail 5, and a top plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com