Tool box for constructional engineering field work measurement

A construction engineering and toolbox technology, which is applied in the field of measuring toolbox devices, can solve problems such as tool damage, increased load, and increased burden on students to carry, so as to achieve the effect of easy search and avoid random shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

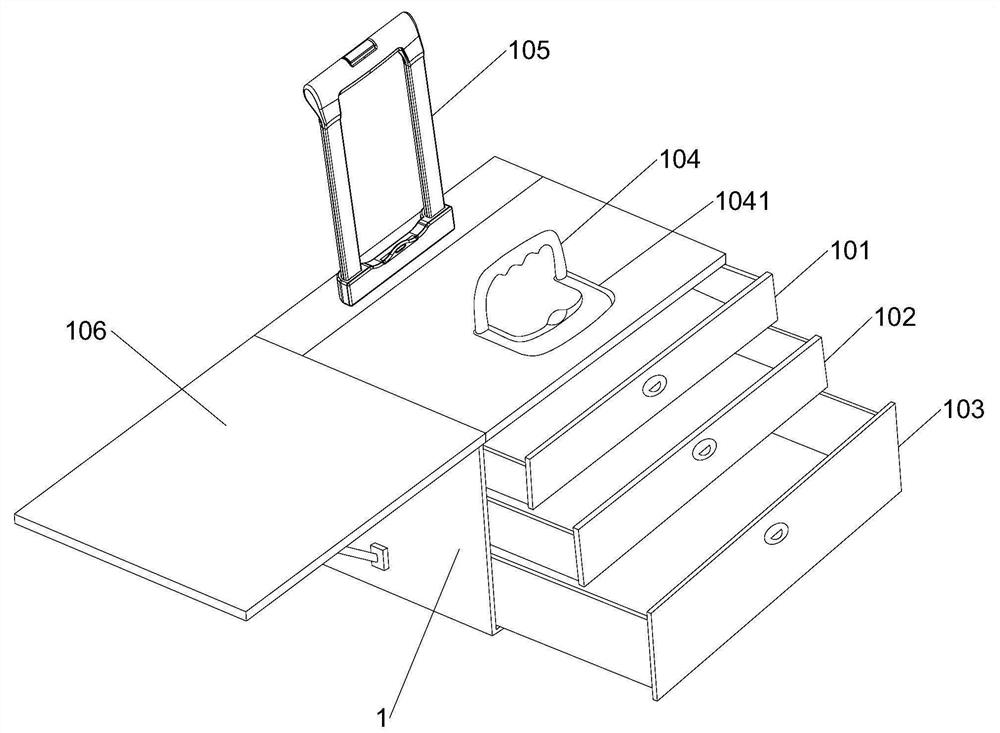

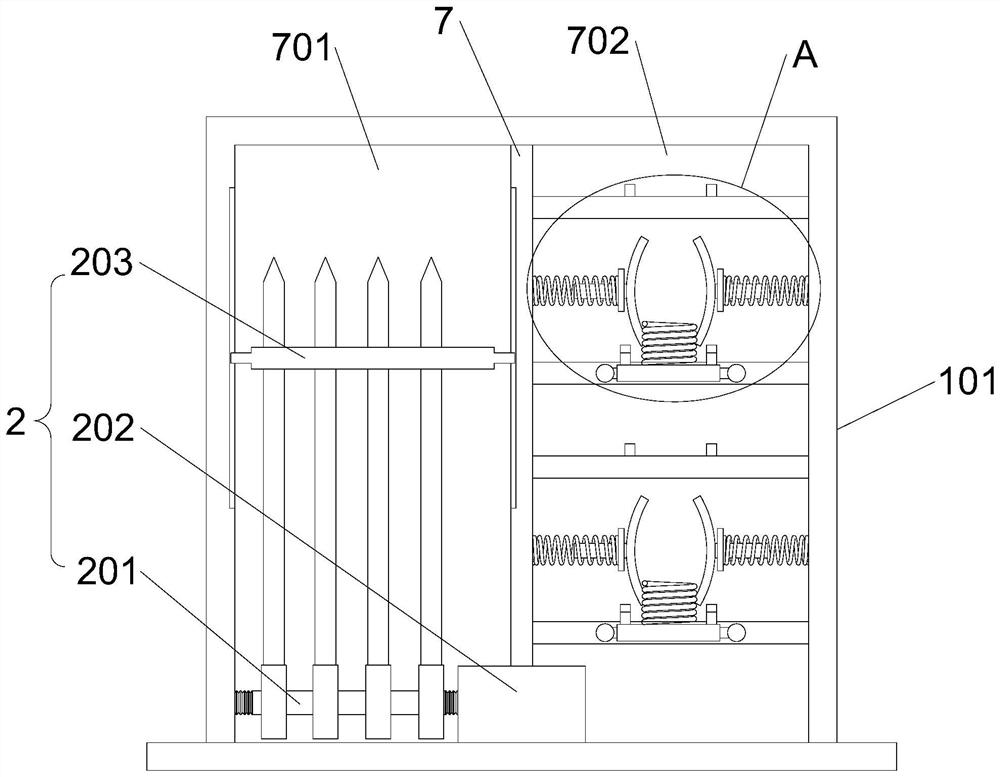

[0039] The toolbox for construction engineering field measurement of the present invention comprises a box body 1, a first drawer 101, a second drawer 102 and a third drawer 103 arranged sequentially from top to bottom are arranged in the box body 1, and the outer wall of the box body 1 is arranged There is a pull rod 105, the side wall of the box body 1 is provided with a folding plate 106, the upper end of the box body 1 is hinged with a handle 104, and the first partition plate 7 is arranged in the first drawer 101 to divide the first drawer 101 into a drilling cavity 701 And the tape measure cavity 702, the drill measuring cavity 701 is provided with a measuring drill fixing part 2, and the tape measure cavity 702 is provided with a tape measure fixing part 3; the middle part of the second drawer 102 is provided with a positioning block 401, and the upper end of the positioning block 401 is provided with a guide plate 4 for positioning A plurality of elastic pressing assemb...

Embodiment 2

[0042] This embodiment is further optimized on the basis of Embodiment 1 as follows: the brazing fixing part 2 includes a sleeve rod 201, a positioning plate 202 and a brazing plate 203; the positioning plate 202 runs through the first partition 7, and the positioning plate 202 is horizontal There is a threaded hole through it, and the outer wall of one end of the sleeve rod 201 is provided with an external thread that is compatible with the threaded hole. A plurality of through holes are opened, and the drilling plate 203 can move along the direction vertical to the sleeve rod 201 . Both ends of the drill measuring plate 203 are provided with limiting projections, and the inner wall of the drill measuring chamber 701 is provided with limiting grooves that are compatible with the limiting projections.

[0043] After adopting the above-mentioned technical scheme: the measuring drill fixing part 2 penetrates through the annular part of the measuring drill through the sleeve rod ...

Embodiment 3

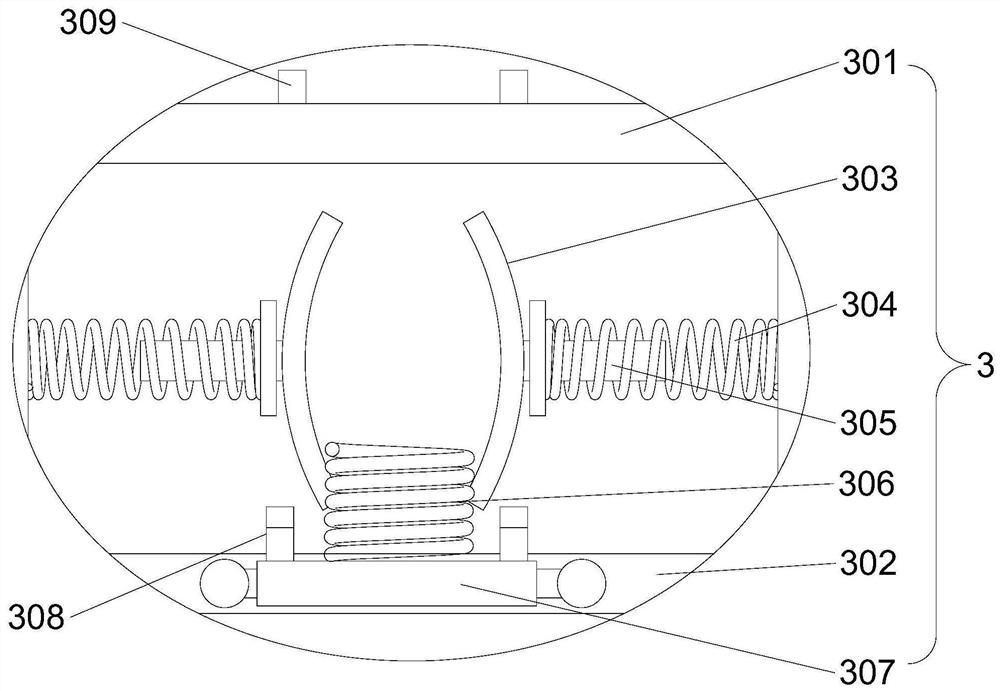

[0045] The present embodiment is further optimized on the basis of Embodiment 1 as follows: the tape measure fixture 3 includes a first support plate 301, a second support plate 302, a pressing plate 303, a pressing spring 304, a cover plate 307, Compression spring 306; the first support plate 301 and the second support plate 302 are arranged in the tape cavity 702 parallel to each other, and the pressing plate 303 is symmetrically arranged between the first support plate 301 and the second support plate 302 , the outer side of the pressing plate 303 is provided with a guide post 305, the pressing spring 304 is sleeved on the guiding post 305, the pressing spring 304 is located between the pressing plate 303 and the inner wall of the tape measure chamber 702, and the cover plate 307 is hingedly mounted on the first On the upper end of the support plate 301, the cover plate 307 is provided with a buckle sub-part 308, the second support plate 302 is provided with a buckle female ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com