Microwave curing device for composite material and curing method thereof

A composite material and microwave curing technology is applied in the field of microwave curing devices for composite materials, which can solve the problems of uneven heating of components and ablation of heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In the following embodiments, the curing material is epoxy resin as an example to illustrate the curing process.

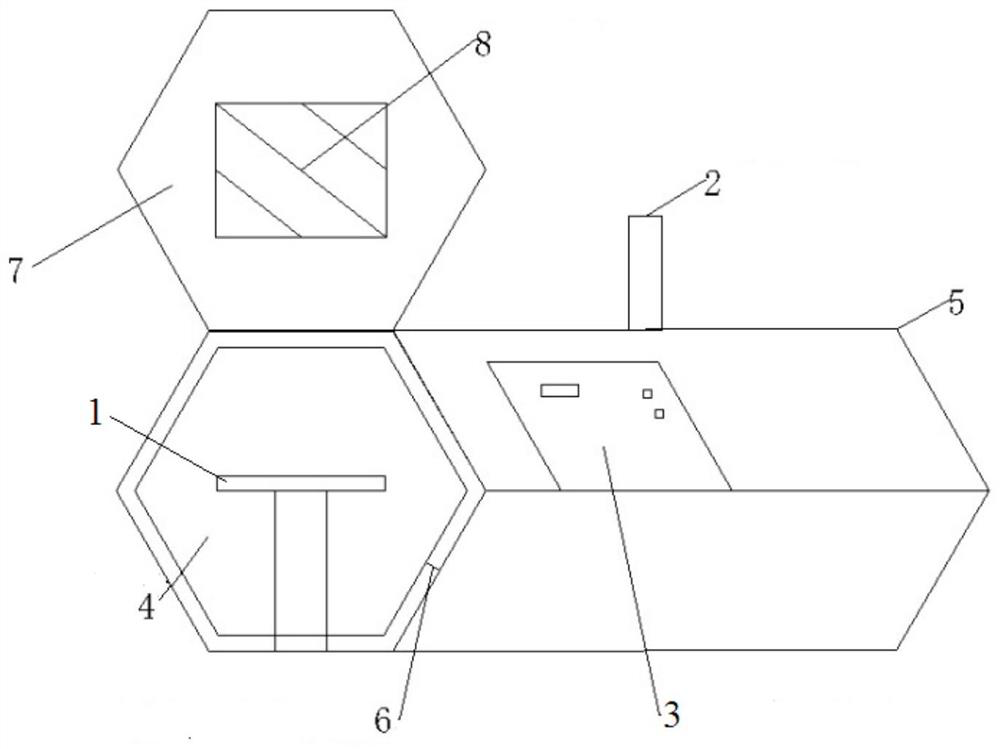

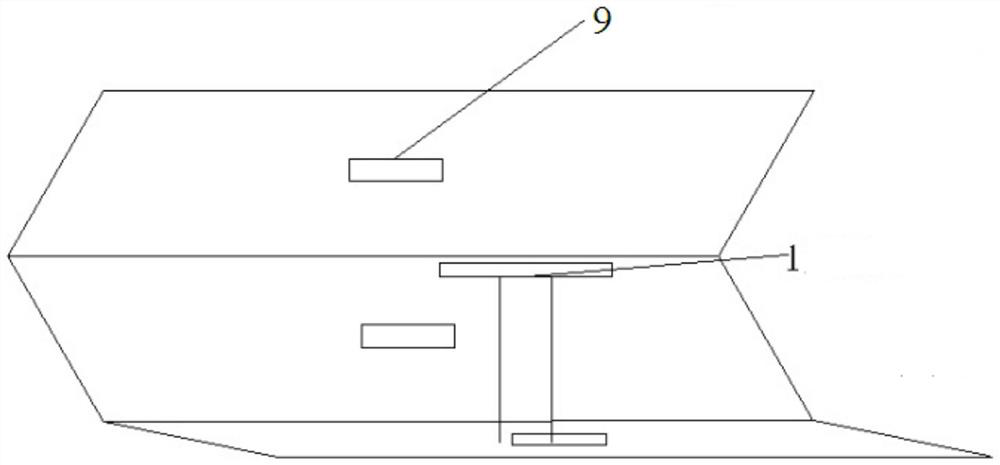

[0049] A microwave curing device for composite materials, the schematic diagram of its overall structure is shown in figure 1 As shown, the internal structure diagram is shown in figure 2 As shown, it includes components such as microwave magnetron 9, microwave cavity 4, storage table 1, magnetron controller, infrared thermal imager 2, vacuum positive and negative pressure bags, and indirect detection device. The microwave cavity 4 is positive 6-sided microwave cavity, in which:

[0050] The storage table is placed in the center of the microwave cavity 4;

[0051] The microwave cavity 4 adopts a double-layer structure, specifically including an inner shell and an outer shell 5, so as to restrain the microwave electromagnetic field to prevent leakage of microwave radiation, facilitate installation and protect the microwave magnetron 9, and the regular hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com