Tempered glass production line

A tempered glass and production line technology, which is applied in glass tempering, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of heavy workload and low utilization rate of tempered glass production line, so as to increase production capacity, improve energy utilization rate, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

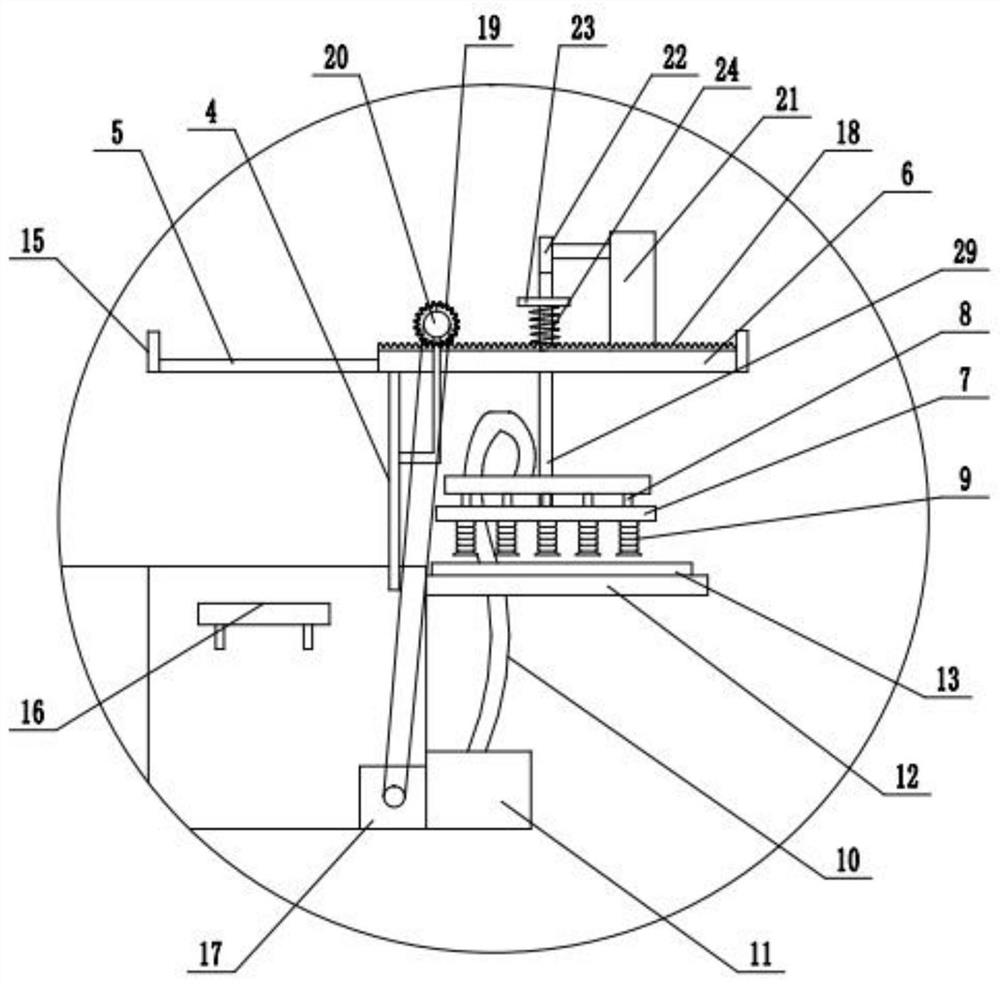

[0022] Further detailed explanation through specific implementation mode below:

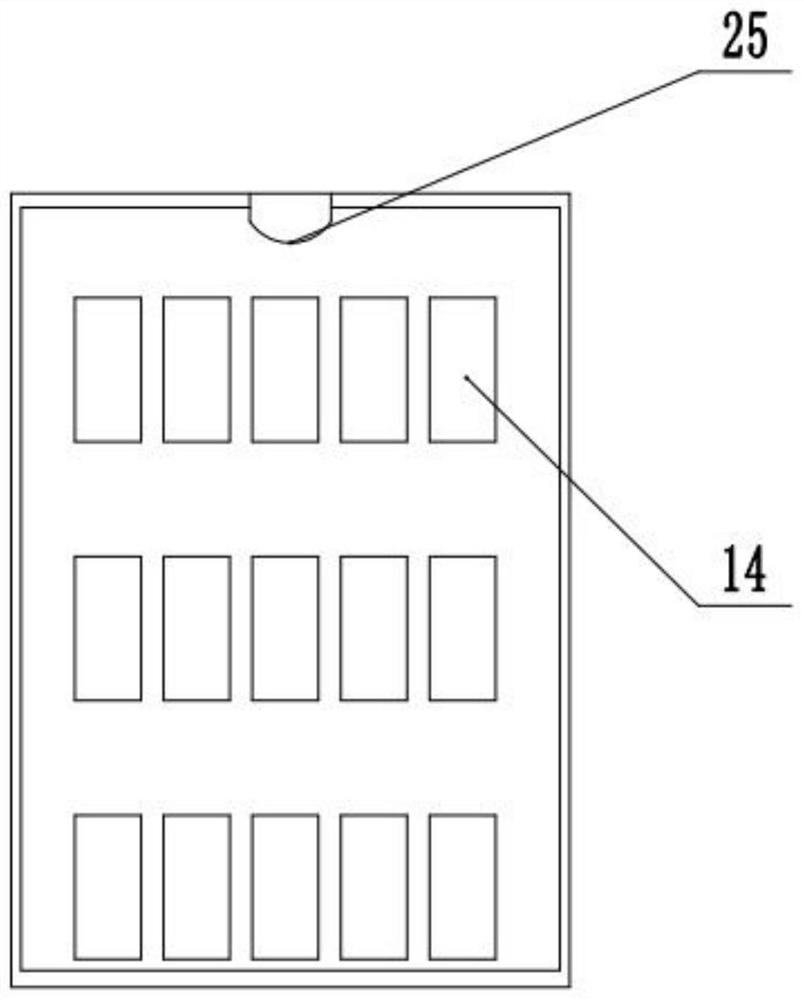

[0023] The reference signs in the drawings of the description include: loading table 1, heating furnace 2, air grid cooling section 3, support frame 4, guide rail 5, horizontal plate 6, pressure plate 7, hollow pin 8, suction cup 9, intake hose 10. Vacuum pump 11, storage table 12, storage board 13, groove 14, position sensor 15, main control unit 16, first motor 17, gear 18, rack 19, sheave 20, second motor 21, cam 22, Limiting block 23, spring 24, positioning projection 25, air floating plate 26, exhaust hole 27, air blower 28, push rod 29.

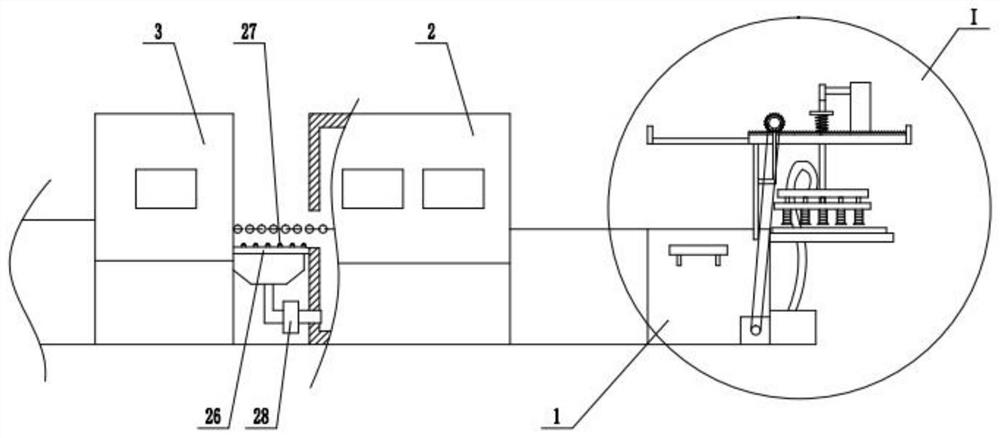

[0024] Example figure 1 and figure 2 As shown, a tempered glass production line includes a loading table 1, a heating furnace 2, an air grid cooling section 3, and a unloading table in sequence. The roller table of the tempered glass production line adopts a ceramic roller table, and the outer periphery of the ceramic roller table is wrapped with heat-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com