Bending resistance, high bonding strength flexible LED encapsulation adhesive and preparation method

A technology of encapsulation adhesive and phosphoric acid group, which is applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problem that it is difficult to meet the long-term use requirements of flexible LED chip encapsulation adhesives, and polyurethane has poor water resistance and heat resistance , The internal stress of the cured product is small, etc., to achieve excellent elastic recovery and stress absorption capacity, excellent impact resistance, and good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

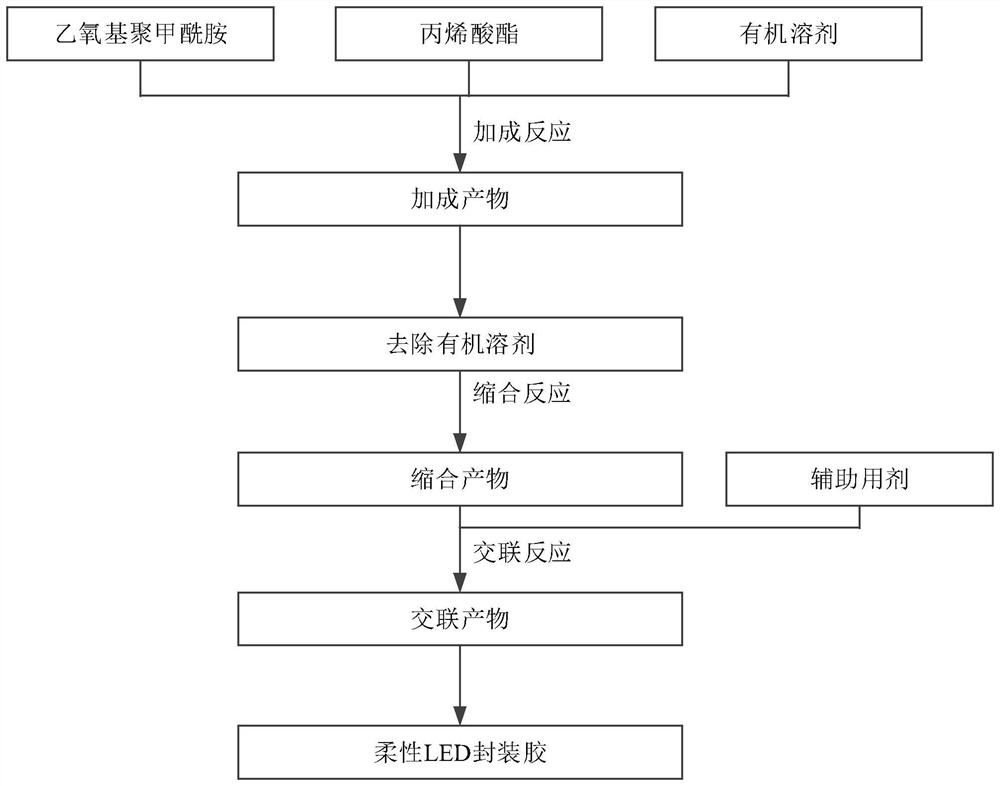

[0034] further, see figure 1 , the present invention also provides a method for preparing an encapsulant, comprising: sequentially mixing ethoxy polyformamide and acrylate containing phosphoric acid groups into an organic solvent; addition reaction to obtain an addition product; removal of the organic solvent; Condensation reaction to obtain condensation products; adding auxiliary agents; cross-linking reaction to obtain cross-linked products.

[0035] Concrete, ethoxypolyformamide can be mixed in organic solvent chloroform, form ethoxypolyformamide chloroform solution, then the acrylate containing phosphoric acid group is dissolved in ethoxypolyformamide chloroform solution; Then in Stir at 50°C for 12 hours to undergo an addition reaction, so that the amino group of ethoxy polyformamide is added to the double bond of acrylate containing phosphoric acid groups to form an addition product; then keep the temperature for about 3 hours under nitrogen flow, remove Organic solvent...

Embodiment 1

[0057] (1) Addition reaction

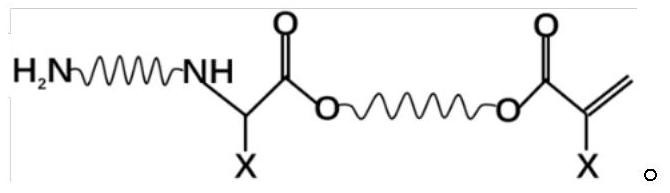

[0058] Ethoxypolyformamide (R=CH 2 , R'=CH 2 , x=1, y=5) 15 mole fractions, ethoxy polyformamide (R=CH 2 , R'=CH 2 , x=1, y=11) 30 mole fractions are dissolved in the chloroform solution, then the polyacrylic acid (R=CH 2 ,X=H) 45 mole fractions are dissolved in ethoxy polyformamide chloroform solution, stirred at 50°C for 12h, so that the amino group of ethoxy polyformamide is added to the double bond of acrylate with phosphoric acid group , to obtain the addition product. The temperature was maintained for about 3 h under nitrogen flow, and the chloroform was removed.

[0059] (2) Condensation reaction

[0060] Raise the temperature to 80°C and keep it for about 4 hours, so that the phosphoric acid group containing acrylate and the amino group of ethoxy polyformamide undergo condensation reaction to obtain a condensation product. And add N,N-dimethylformamide to obtain a uniform and transparent polymer solution.

[0061] (3) Cross-linki...

Embodiment 2

[0064] (1) Addition reaction

[0065] Ethoxypolyformamide (R=CH 2 , R'=CH 2 , x=1, y=5) 22.5 mole fractions, ethoxypolyformamide (R=CH 2 , R'=CH 2 , x=1, y=11) 22.5 mole fractions were dissolved in chloroform solution, and polyacrylic acid (R=CH 2 , X=H) 45 mole fractions are dissolved in ethoxy polyformamide chloroform solution, stirred at 50°C for 12h, so that the amino group of ethoxy polyformamide is added to the double bond of acrylate with phosphoric acid group , to obtain the addition product. The temperature was maintained for about 3 h under nitrogen flow, and the chloroform was removed.

[0066] (2) Condensation reaction

[0067] Raise the temperature to 80°C and keep it for about 4 hours, so that the phosphoric acid group containing acrylate and the amino group of ethoxy polyformamide undergo condensation reaction to obtain a condensation product. And add N,N-dimethylformamide to obtain a uniform and transparent polymer solution.

[0068] (3) Cross-linking r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com