Preparation method of carbon-based difunctional soil remediation agent, product and remediation method

A soil remediation agent and dual-function technology, which is applied in the field of preparation of carbon-based dual-function soil remediation agent, can solve the problems of inability to meet the supplementary nutrient requirements of barren soil and low repair efficiency, and achieve suitable scale promotion, improve fixation capacity, and repair The effect of cycle improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

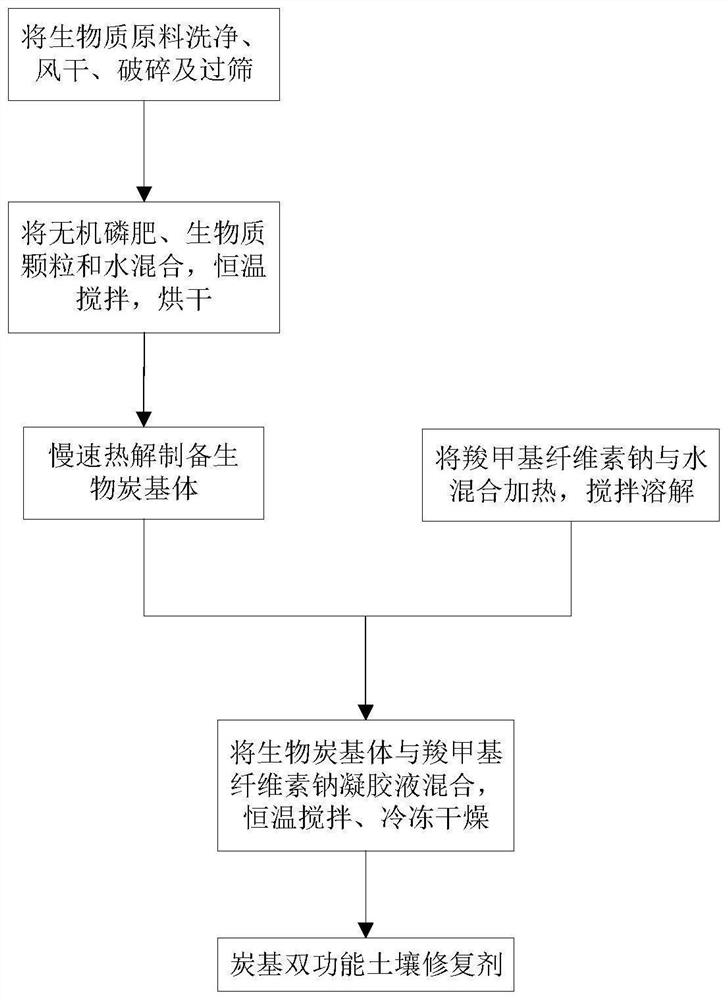

[0031] Such as figure 1 Shown, a kind of preparation method of carbon-based dual-function soil remediation agent, it comprises the steps:

[0032] (1) drying the biomass raw material, pulverizing, and sieving to obtain biomass particles;

[0033] (2) Mix biomass particles, phosphate fertilizer, and water, stir evenly at a set temperature, and evaporate the above mixture to obtain a biochar precursor;

[0034] (3) Slowly heat the precursor to a set temperature under anaerobic or hypoxic conditions and keep it for a period of time for pyrolysis to obtain a biochar matrix;

[0035] (4) Sodium carboxymethyl cellulose is mixed with water, stirred at a set temperature, until sodium carboxymethyl cellulose is completely dissolved, and sodium carboxymethyl cellulose gel is obtained;

[0036] (5) Mixing the biochar matrix and the gel solution in a certain ratio, stirring evenly, and freeze-drying to obtain a carbon-based dual-function soil remediation agent.

[0037] Further, step (...

Embodiment 1

[0049] 1. Preparation of carbon-based bifunctional soil remediation agent

[0050] (1) 3kg moso bamboo slices are washed with water and then dried, then pulverized with a pulverizer through an 80-mesh sieve, and the bamboo particles with a particle diameter of less than 0.180mm are dried again, and put into a storage tank for subsequent use;

[0051] (2) adopt the method of solvothermal treatment, according to moso bamboo granules: potassium dihydrogen phosphate fertilizer (KH 2 PO 4 , where P 2 o 5 The content is about 52wt.%, K 2 O content is about 34wt.%) The ratio of mass ratio is 5:1 Take 0.6kg phosphate fertilizer and moso bamboo granule mix, add 14.4kg water (solid-to-liquid ratio is 1:4) and move into the stirrer that has been heated to 80 ℃ and stir 2h, the mixture is dried to obtain a biochar precursor;

[0052] (3) Place the precursor in step (2) in a fixed-bed reaction device to raise the temperature from room temperature to the optimal working condition of 55...

Embodiment 2

[0062] 1. Preparation of carbon-based bifunctional soil remediation agent

[0063] (1) Wash 0.5 kg of corn stalks with water and dry them, then use a pulverizer to crush them through a 120-mesh sieve, dry the corn stalks with a particle size less than 0.125 mm, and put them into a storage tank for subsequent use;

[0064] (2) Solvent heat treatment is adopted, according to the corn stalk particles: superphosphate fertilizer (Ca(H 2 PO 4 ) 2 , where P 2 o 5 The content is between 14wt.%~20wt.%), the mass ratio is 1:5, mix 2.5kg of phosphate fertilizer with corn stalk granules, add 24kg of water (solid-to-liquid ratio is 1:8) and move it into the 90°C heated Stirring in a stirrer for 8h, drying the mixture to obtain a biochar precursor;

[0065] (3) Put the precursor in step (2) in a fixed-bed reaction device and raise the temperature from room temperature to the optimal working condition of 750 °C at a rate of 10 °C / min, keep the pyrolysis temperature for 2 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com