Method for reinforcing water-rich silt strata by obliquely arranging multiple rows of freezing pipes

A technology for freezing pipes and silt, applied in soil protection, infrastructure engineering, construction and other directions, can solve problems such as large environmental pollution, freezing of excavation areas, and impact on the stability of groove walls, achieving simple method steps and reducing Wall collapse, easy to promote the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

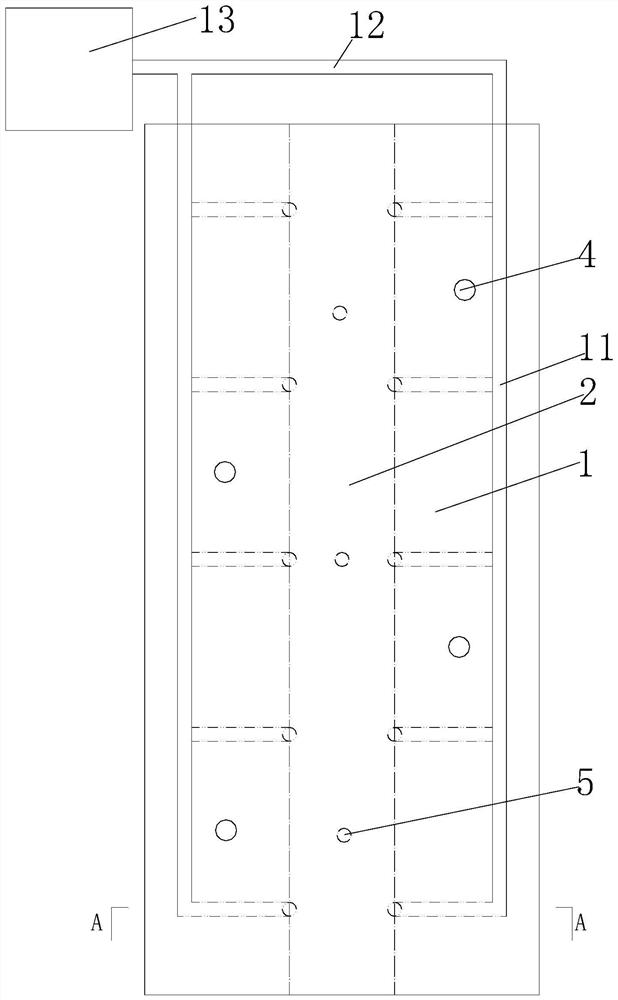

[0040] Such as Figure 1 to Figure 8 As shown, the method for reinforcing the water-rich silt formation with inclined arrangement of multiple rows of freezing pipes of the present invention comprises the following steps:

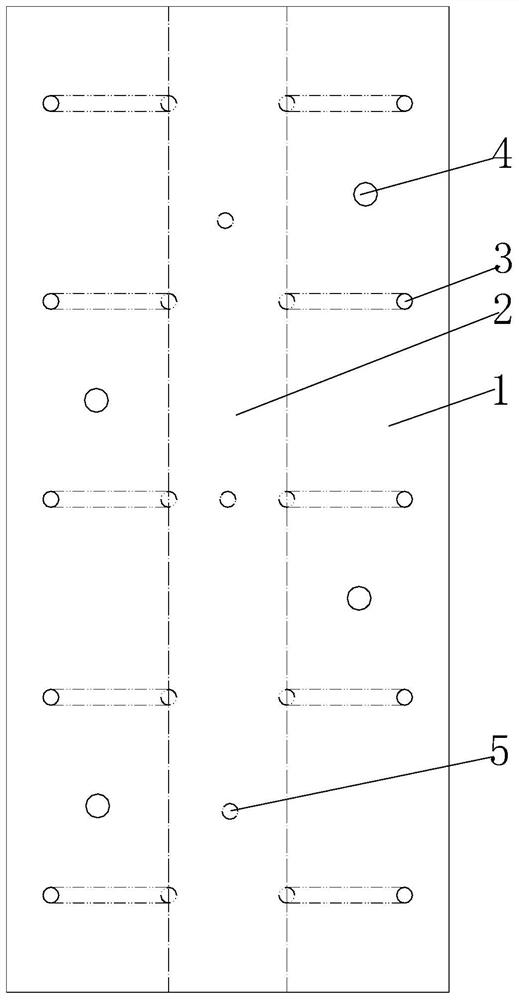

[0041] Step 1. Measurement and setting out: explore the water-rich silt sand stratum, confirm the thickness and depth distribution of the water-rich silt sand stratum, investigate the distribution of groundwater, pressure bearing size, and seepage pressure distribution, obtain the number, spacing and inclination angle of freezing holes, and determine the temperature measurement at the same time The position and quantity of holes 4 and pressure relief holes 5;

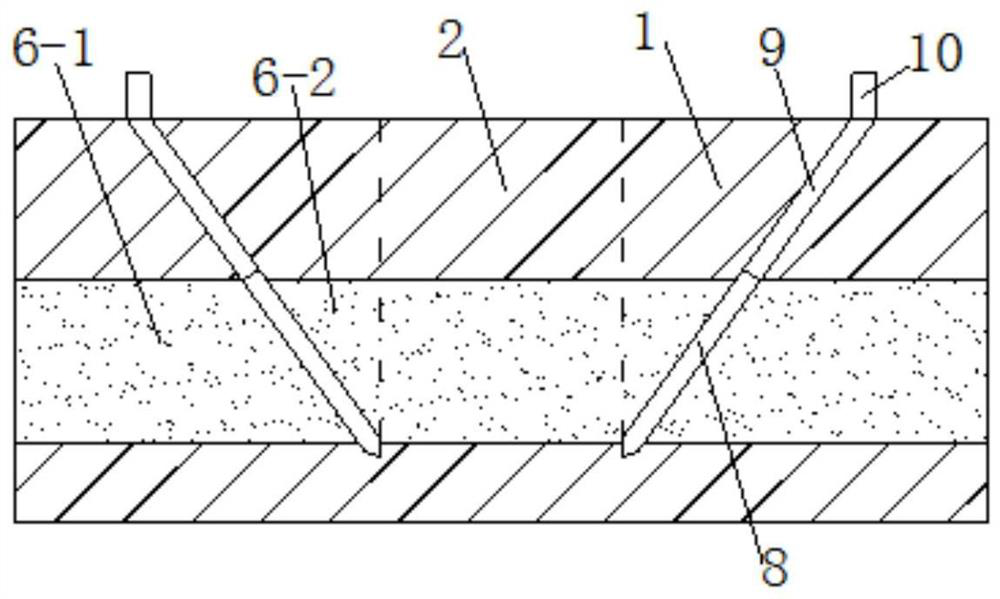

[0042] The freezing hole is an inclined hole 3, and the inclined hole 3 is symmetrically arranged in pairs along the length direction of the groove to be excavated;

[0043] Step 2. Drilling with the pipe: use the inclined hole drilling machine to drill the inclined hole 3 at the designed position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com