Secondary water supply living water tank with automatic cleaning function

A secondary water supply and automatic cleaning technology, which is applied in the direction of water supply devices, configuration of water supply pools, cleaning methods and appliances, etc., can solve the problems of secondary pollution of water quality, long time consumption, large cleaning area, etc., and reduce difficulty and workload , avoid interference, and improve the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

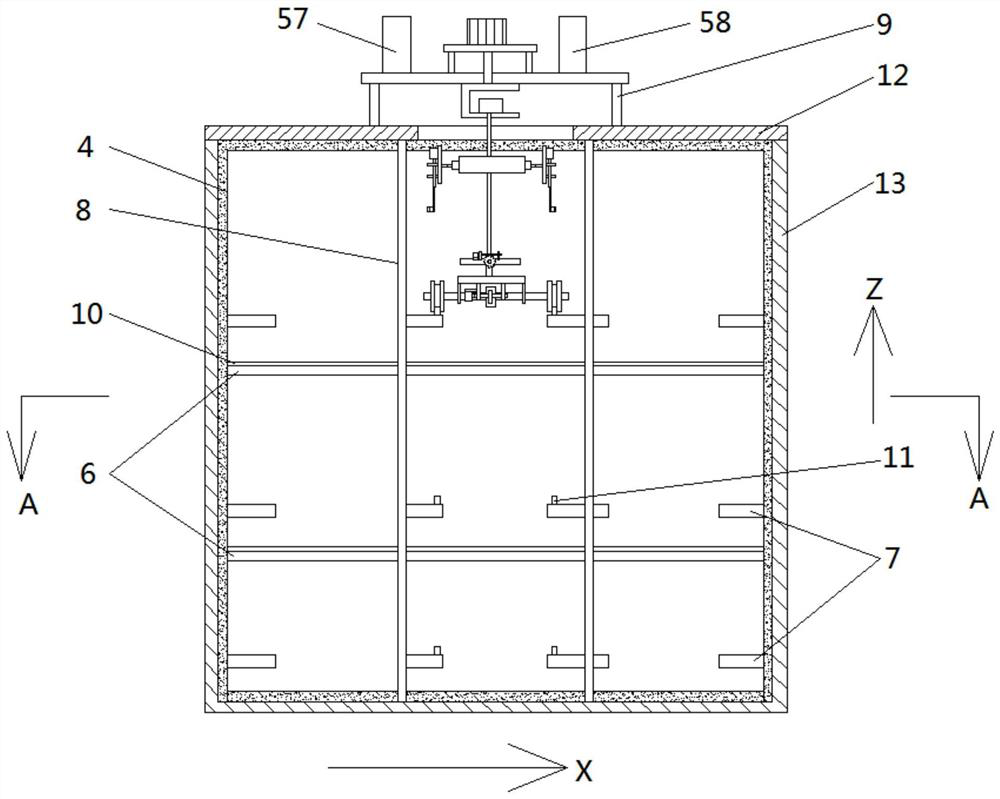

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

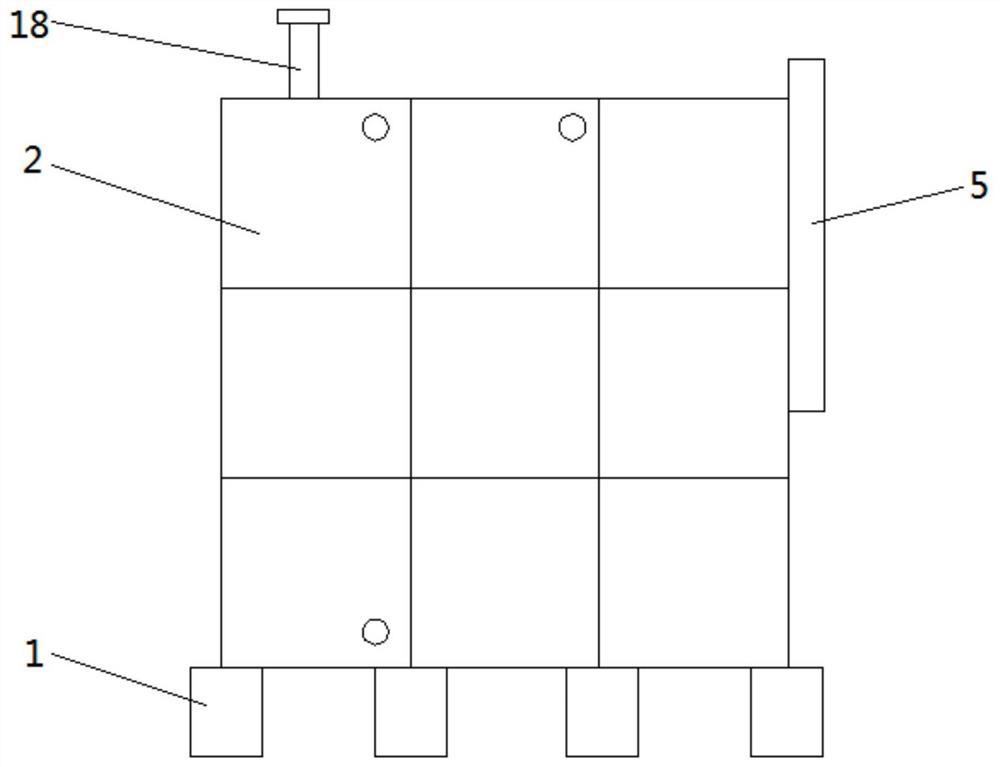

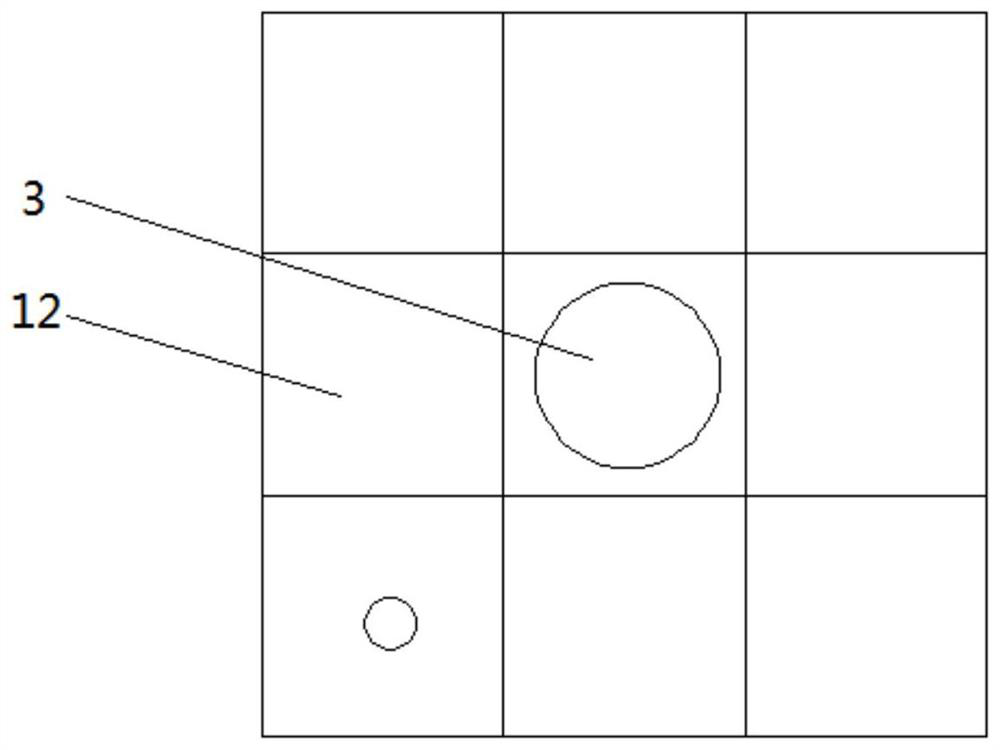

[0031] A secondary water supply domestic water tank with automatic cleaning function, comprising a concrete foundation 1, a water tank body 2 installed on the concrete foundation 1, a manhole cover detachably installed on the top of the water tank body 2 and located at the center of the water tank body 2 3. The external ladder 5 installed on the water tank body 2, the support frame 4 welded in the water tank body 2 and located on each side of the water tank body 2, and the multi-row transverse tie rods 6 welded in the water tank body 2 and distributed along the Z direction , the multi-row longitudinal tie rods 7 welded in the water tank body 2 and distributed along the Z direction, located below the transverse tie rods 6, the support rods 8 welded in the water tank body 2 and parallel to the Z direction, distributed in a matrix of multiple rows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com