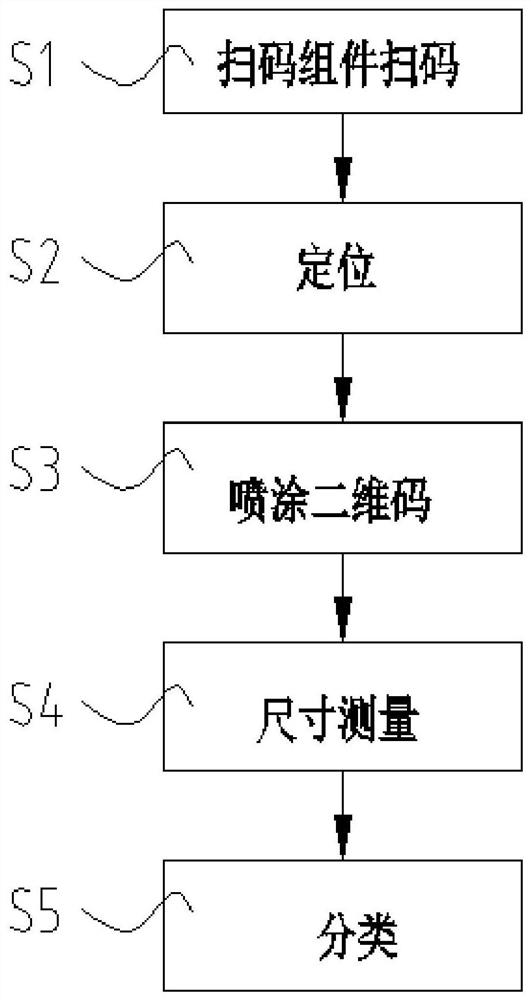

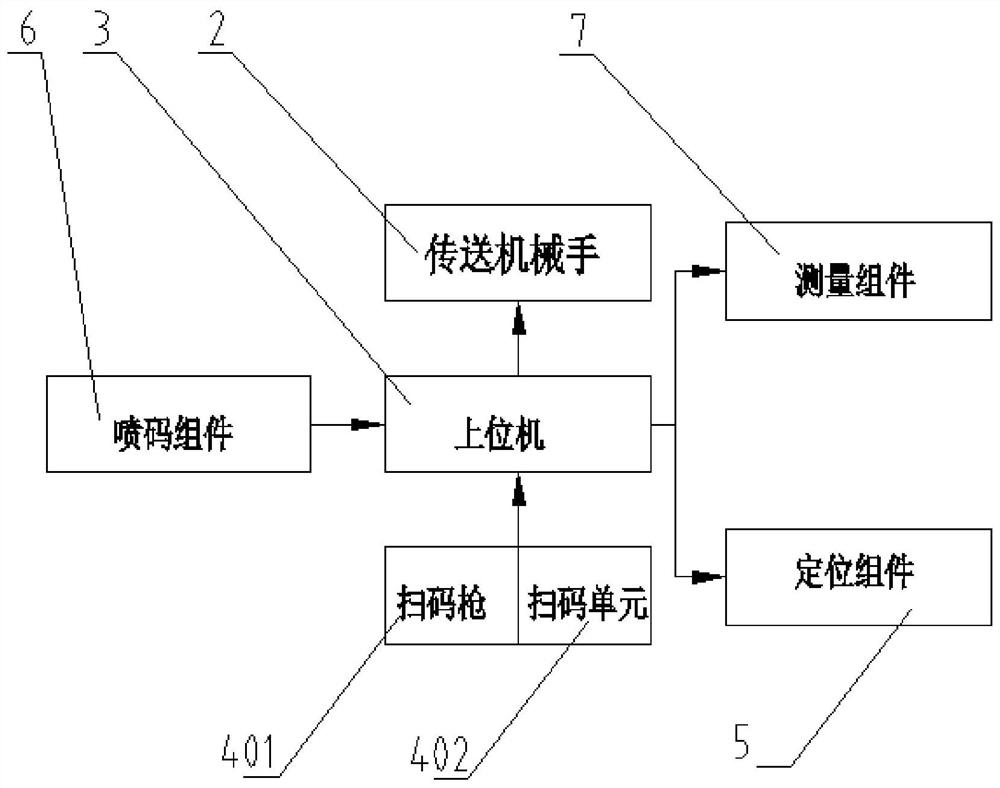

Standard sample size measurement method, system and application

A standard sample and measurement system technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as inability to classify samples, and achieve the effect of reducing time and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

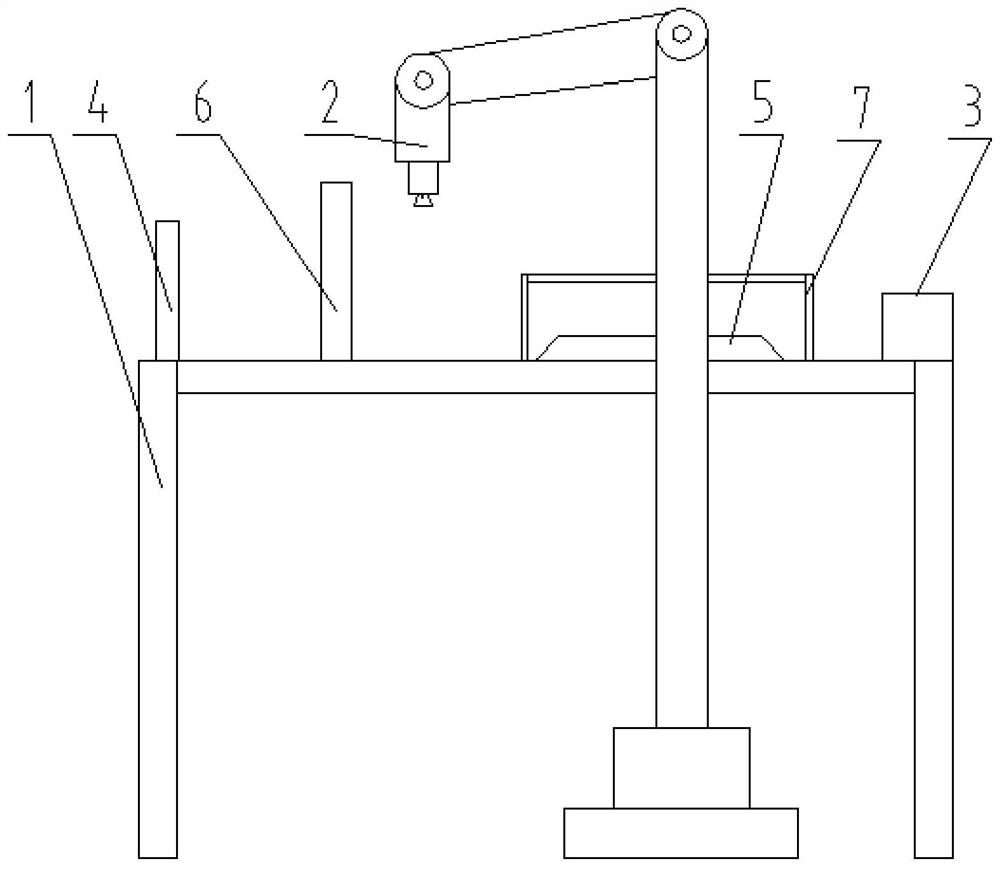

[0061] Embodiment 1: Since the sample 8 needs to be measured after the fixing assembly 5 is fixed, if the laser head is used for linear scanning measurement, the sample 8 needs to be fixed to prevent the sample 8 from moving and affecting the measurement result.

[0062] In actual work, such as Figure 5-6 , the measuring component 7 can measure the length, width and thickness of the sample 8 through the laser distance measuring unit; at the same time, in the process of using the laser distance measuring, in order to ensure the accuracy of the measurement result, the sample 8 is at rest through the fixed component 5 State, while the laser distance measuring unit on the measurement component 7 can move linearly, and measure the size data of the sample 8 by scanning.

[0063] Specifically, the fixing assembly 5 includes a base plate 501, a negative pressure unit 502, and a positioning unit 503 which are arranged on the frame 1 through bolts; wherein, the edge of the base plate ...

Embodiment II

[0071] Embodiment II: as Figure 10-11 , in actual work, the measurement component 7 can measure the length, width and thickness of the sample 8 through the CCD; since the CCD is used to measure the size of the object without linear motion, the sample 8 can be placed at a designated position.

[0072] In order to complete the CCD size measurement, the fixed assembly 5 includes a transparent bottom plate 501, a positioning unit 503 and an illumination unit arranged on the frame 1; the measurement assembly 7 includes a CCD linear array 704; wherein, the bottom plate The edge of 501 is provided with a row of at least two positioning units 503; wherein, the positioning unit 503 cooperates with the positioning device on the transfer manipulator 2, and is used to place the sample 8 in the object field of view of the imaging objective lens and place the CCD The linear array image sensitive surface is set on the best image plane position of the imaging objective lens, and the measurem...

specific Embodiment III

[0076] Specific embodiment III: Of course, in the process of specific implementation, it is also possible to adopt the mixed use of linear scanning method and CCD linear array 704 .

[0077] As: the fixed assembly 5 includes a transparent bottom plate 501, a positioning unit 503 and an illumination unit arranged on the frame 1; the measurement assembly 7 includes a CCD linear array 704 for measuring the length and width of the sample 8, The first sliding rail mechanism 701 for measuring the thickness of the sample 8;

[0078] Wherein, the edge of the bottom plate 501 is provided with a row of at least two positioning units 503 and cooperates with the positioning device on the transfer manipulator 2 for placing the sample 8 in the object field of view of the imaging objective lens and placing the CCD linear array The image sensitive surface is set on the best image surface position of the imaging objective lens, and the measurement is completed through the illumination of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com