Noise-removing laminating machine

A laminating machine, noise technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as high noise in mechanical operation, and achieve the effect of avoiding safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

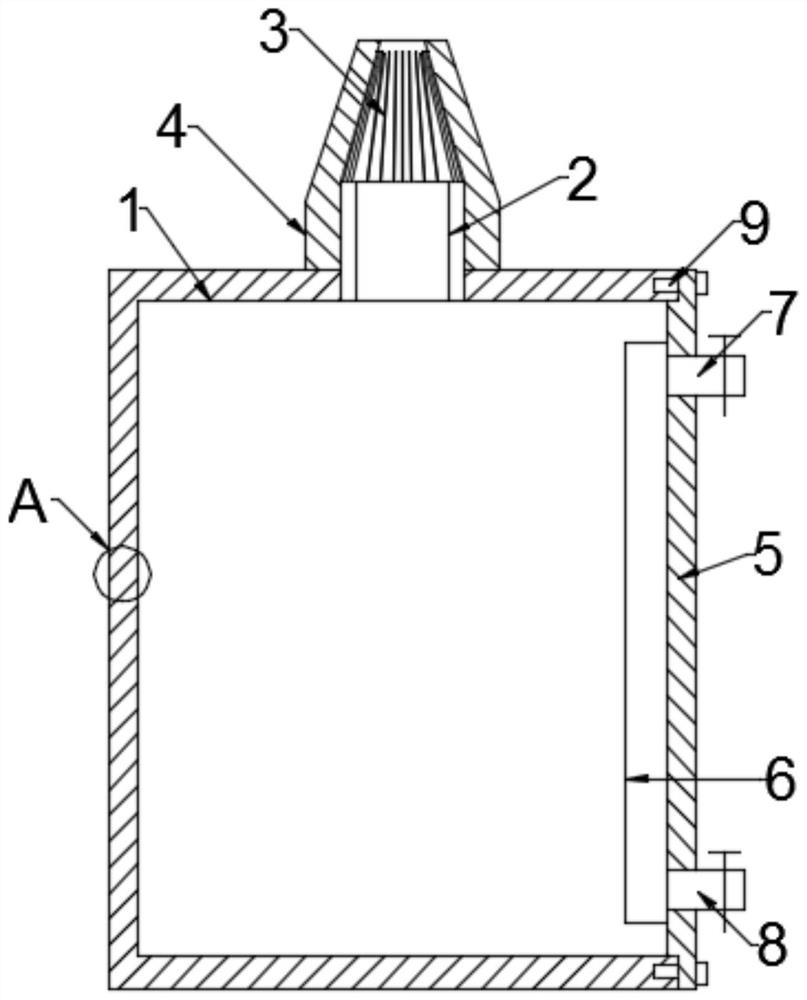

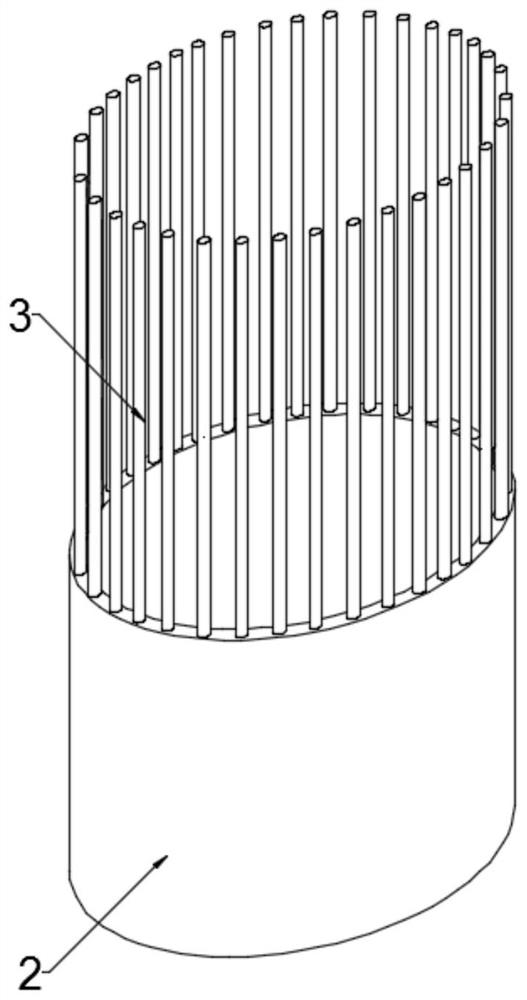

[0023] see Figure 1~3 , in an embodiment of the present invention, a noise-removing laminating machine includes a machine body 1, an access panel 5 is installed on one side of the body 1 through connecting bolts 9, and the access panel 5 is installed on the side of the body 1 There is a heat exchange type heat dissipation mechanism, the upper end of the body 1 is connected with a wiring tube 2, the wiring tube 2 is assembled and connected with a limit sleeve 4, and the side wall of the body 1 and the inspection panel 5 is embedded. There is an interlayer 10, and the interlayer 10 is filled with a sound-absorbing interlayer.

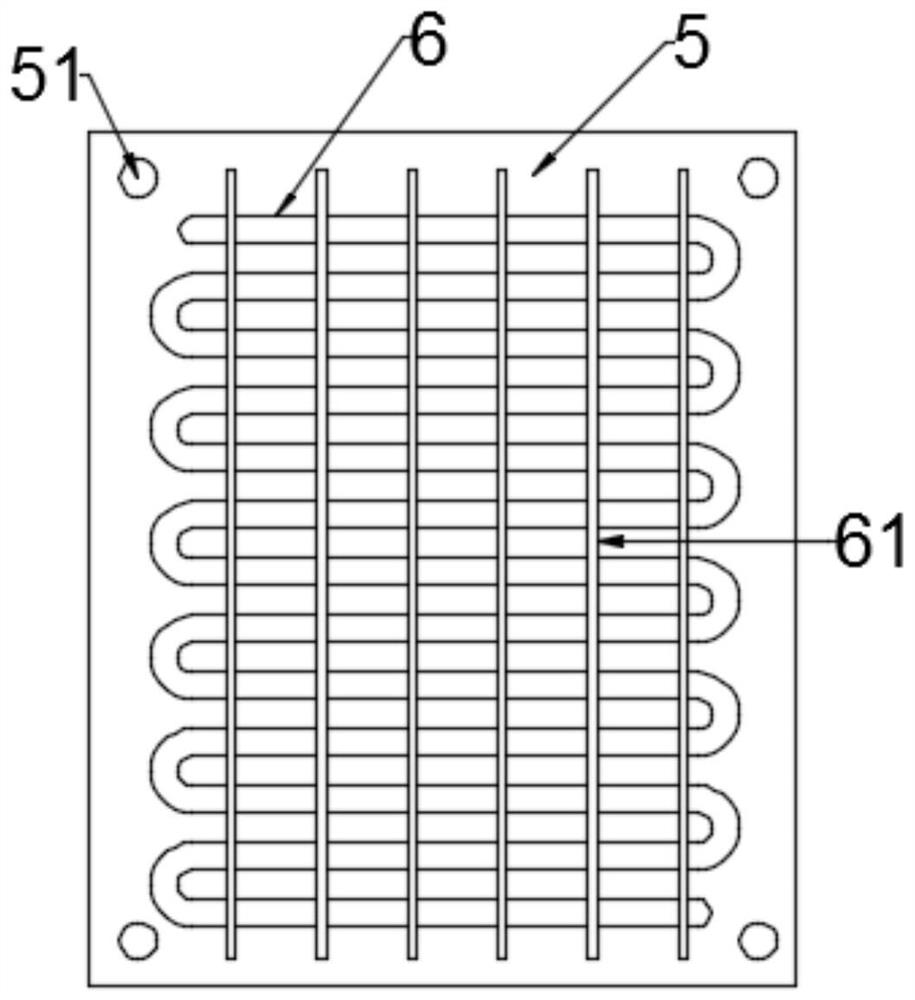

[0024] Mounting holes 51 are provided through the four top corners of the access panel 5 , and the mounting holes 51 are movably fitted with the connecting bolts 9 .

[0025] The heat exchange type heat dissipation mechanism includes a heat dissipation pipe 6, and the heat dissipation pipe 6 is attached to the side of the inspection panel 5. The periphe...

Embodiment 2

[0030] see Figure 4 , in the embodiment of the present invention, a kind of noise-removing laminating machine, on the basis of embodiment 1, described sound-absorbing interlayer comprises filling inner core 12, and described filling inner core 12 is the foam plate of honeycomb structure, and described The filling inner core 12 is filled and arranged in the interlayer 10, so that the weight of the device shell can be reduced and the noise reduction effect can be improved at the same time.

[0031] The interlayer 10 is also fixedly connected with a reinforcing plate 11, the reinforcing plate 11 is a continuously bent aluminum alloy plate, and the bent corners of the reinforcing plate 11 are respectively connected to the two side walls in the interlayer 10 to reinforce The arrangement of the plate 11 can support the interlayer 10 to improve the structural stability of the machine body 1, which is safer and more practical in use.

[0032] The standard parts used in the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com