A fireproof insulation board and its preparation process

A fire-resistant insulation board and a preparation technology, which is applied in the field of building materials, can solve the problems of low thermal conductivity of nest-type thermal insulation boards, difficulty in ensuring later strength, and insufficient toughness of insulation boards, etc., to achieve superior heat reflection performance and improve construction efficiency , the effect of excellent thermal resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

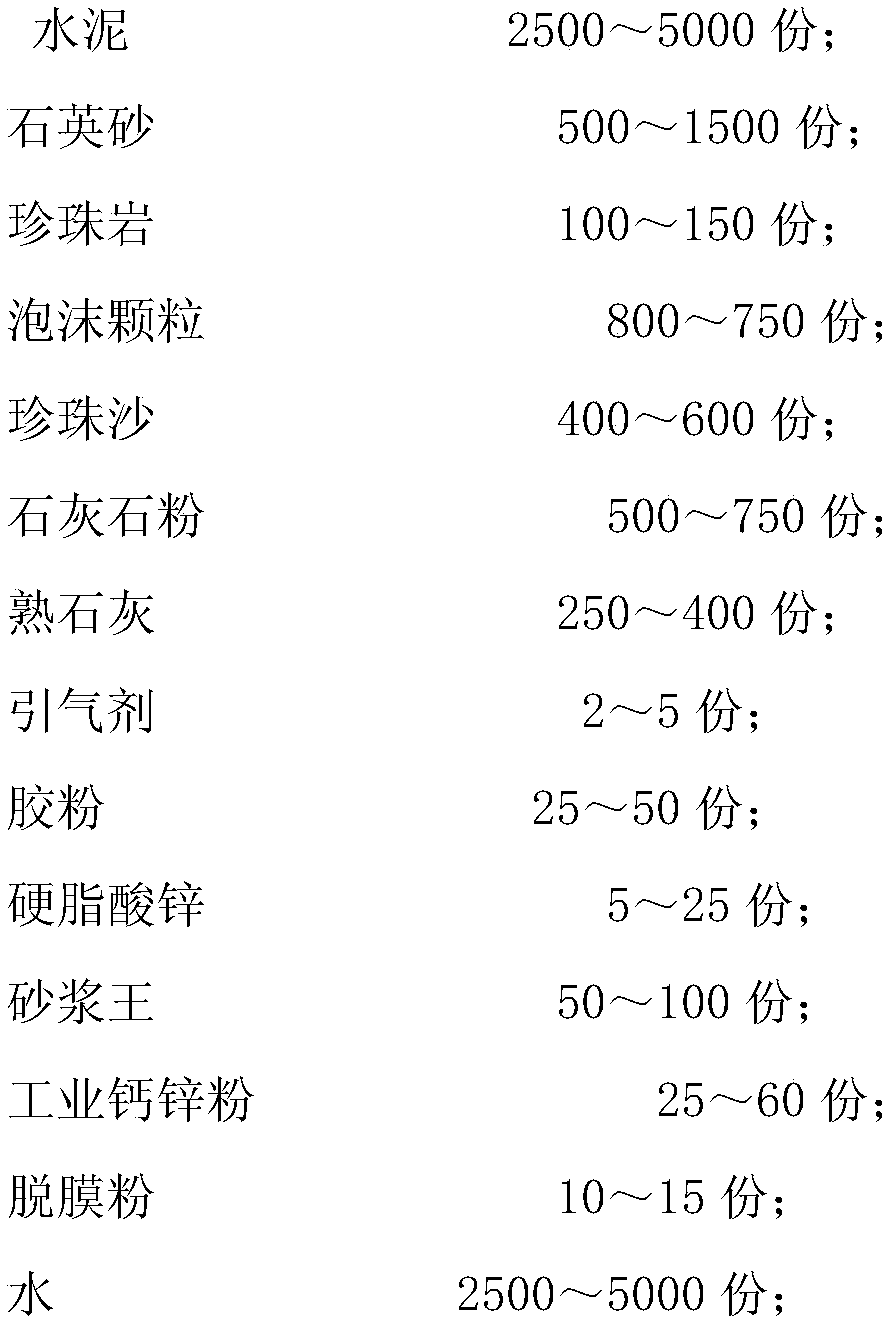

[0036] A fireproof insulation board, which includes the following components (unit: g / m 2 ):

[0037] Cement 2500;

[0038] Quartz sand 1250;

[0039] Perlite 115;

[0040] Foam particles 550;

[0041] Pearl sand 400;

[0042] limestone powder 500;

[0043] Slaked lime 300;

[0044] Air-entraining agent 2;

[0045] Rubber powder 25;

[0047] Mortar King 50;

[0048] Industrial calcium zinc powder 30;

[0049] Release powder 10;

[0050] Water 2500.

[0051] Wherein each raw material is from conventional commercially available products, and will not be repeated here.

[0052] The technological process of the fireproof insulation board includes:

[0053] 1) One-time stirring fermentation: put the weighed raw materials into the mixing equipment and stir them evenly, and the one-time stirring fermentation is completed when the mixed slurry changes from off-white to gray-black and the volume expands and bubbles;

[0054] 2) Secondary vibrati...

Embodiment 2-5

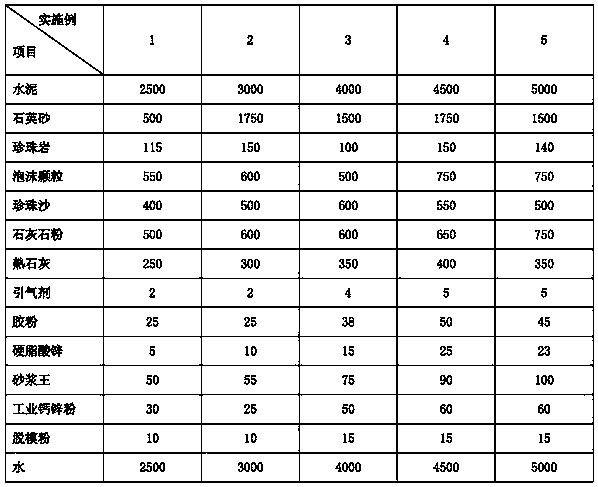

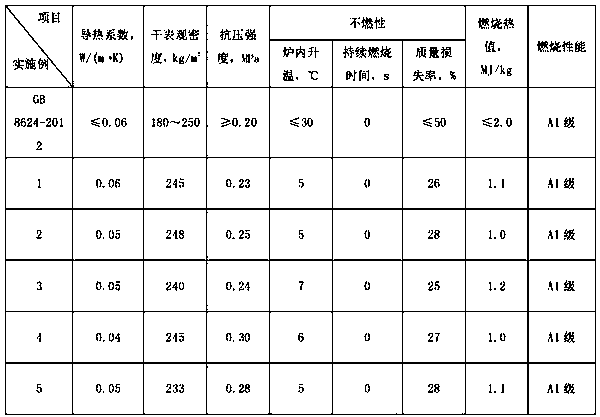

[0057] Embodiment 2-5 adopts the raw material and processing technology identical with embodiment 1, and difference is that the consumption of each composition is different in the raw material, and the formula of each embodiment is as shown in table 1:

[0058] Table 1

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com