A kind of production method of composite fiber automobile carpet

A technology of composite fibers and production methods, which is applied in chemical instruments and methods, special positions of vehicles, synthetic resin layered products, etc. Lightweight and other issues, to achieve the effect of improving work efficiency, reducing weight, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

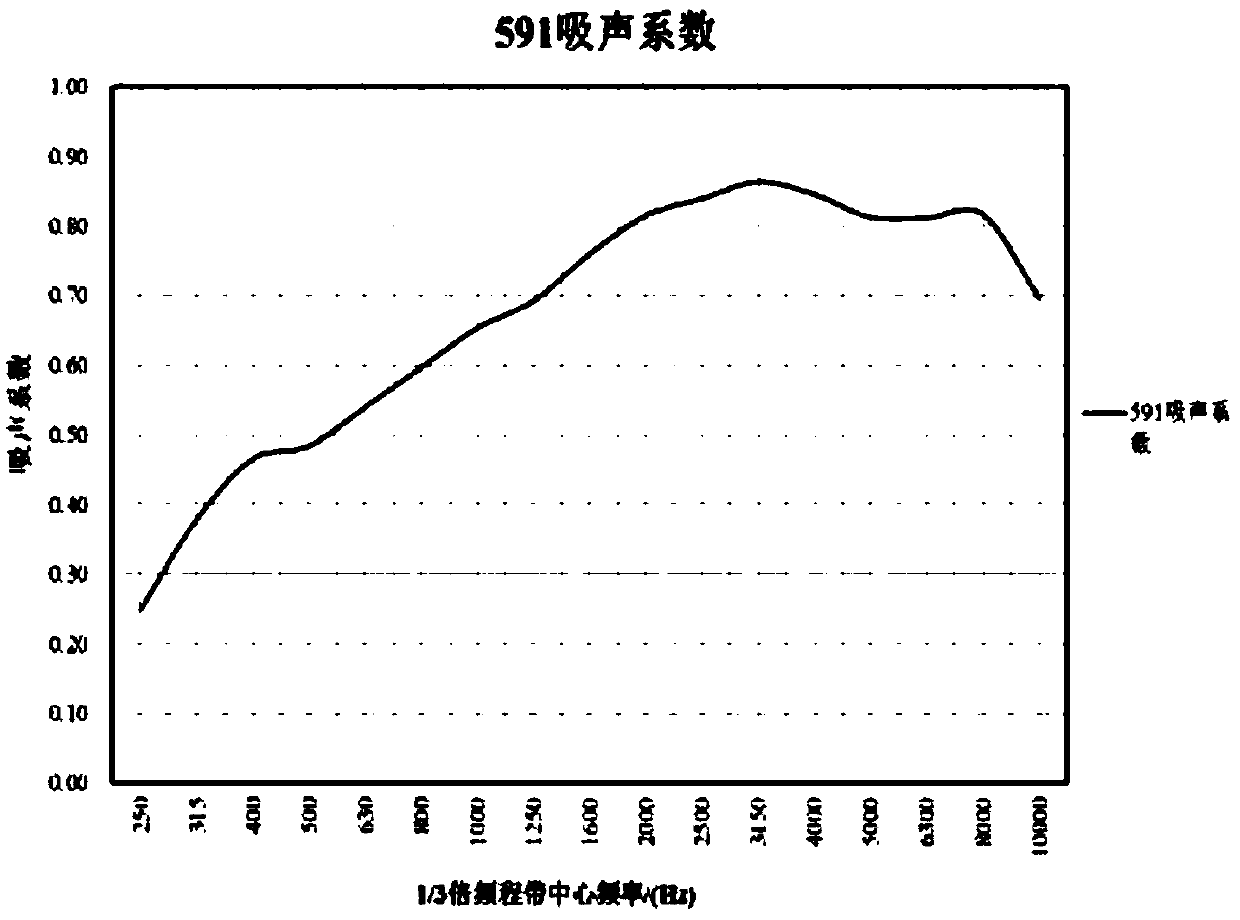

[0028] Produce Dongfeng Nissan 591 car carpet (black), its specification is: 2100mm×1650mm, its production method is as follows:

[0029] a. A composite fiber material composed of PET fluff layer, PET-P layer, low-melting point PET layer and PET coating is selected, and the weight of the composite fiber material is 1400g / m 2 , the thickness of the composite fiber material is 10mm, a piece of EVA heavy coating material is placed on the PET coating of the composite fiber material, and the weight of the EVA heavy coating material is 1800g / m 2 , the thickness of EVA heavy coating material is 1mm, obtains carpet substrate;

[0030] b. Put the carpet substrate into an oven for heating. When heating, the temperature of the upper oven is controlled at 320°C, the temperature of the lower oven is controlled at 230°C, and the drying time is controlled at 70 seconds;

[0031] c. Put the heated carpet base material between the upper mold and the lower mold of the compression molding machi...

Embodiment 2

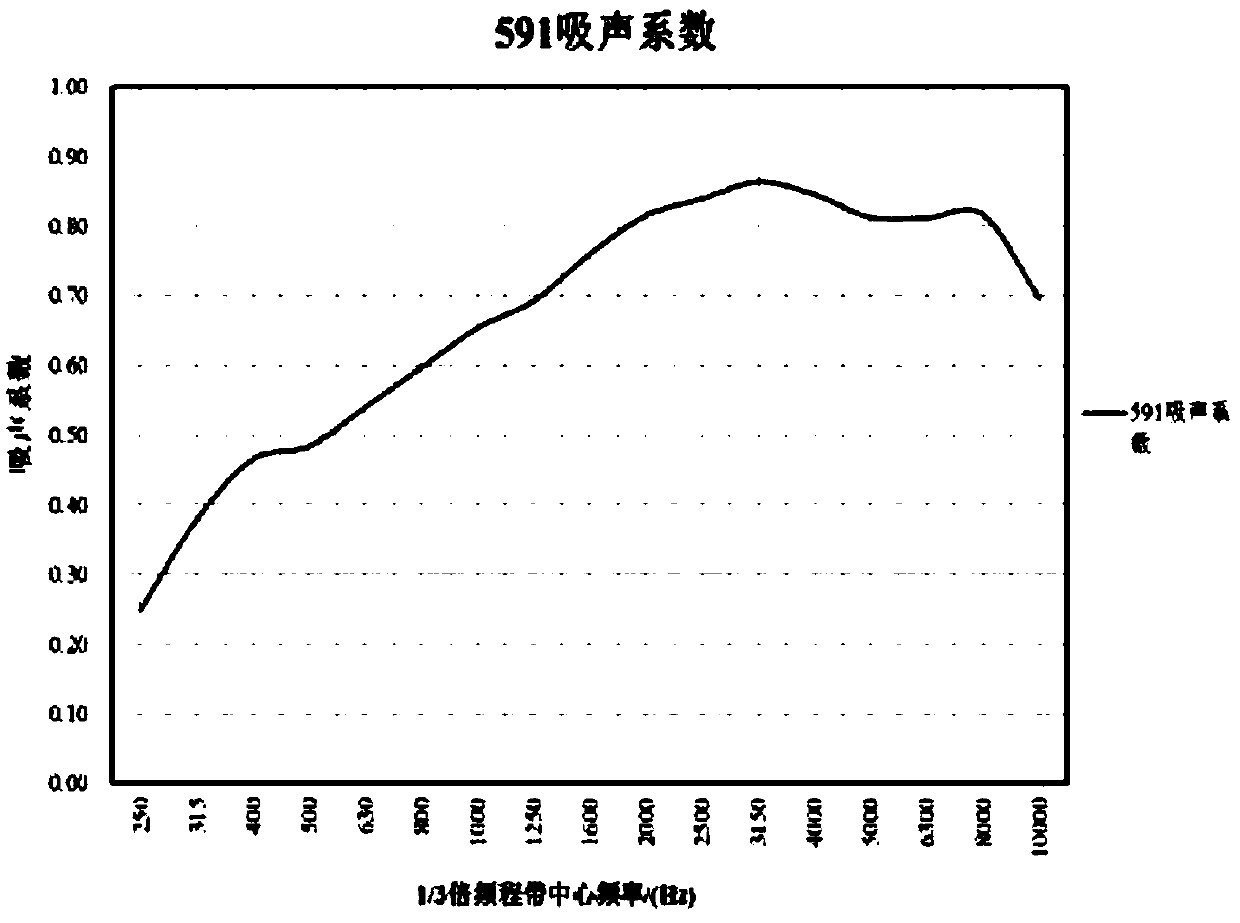

[0038] Produce Dongfeng Nissan 591 car carpet (beige), its specification is: 2100mm×1650mm, its production method is as follows:

[0039] a. A composite fiber material composed of PET fluff layer, PET-P layer, low-melting point PET layer and PET coating is selected, and the weight of the composite fiber material is 1700g / m 2 , the thickness of the composite fiber material is 15mm, a piece of EVA heavy coating material is placed on the PET coating of the composite fiber material, and the weight of the EVA heavy coating material is 2200g / m 2 , the thickness of EVA heavy coating material is 3mm, obtains carpet substrate;

[0040] b. Put the carpet substrate into an oven for heating. When heating, the temperature of the upper oven is controlled at 360°C, the temperature of the lower oven is controlled at 280°C, and the drying time is controlled at 90 seconds;

[0041] c. Put the heated carpet base material between the upper mold and the lower mold of the compression molding machi...

Embodiment 3

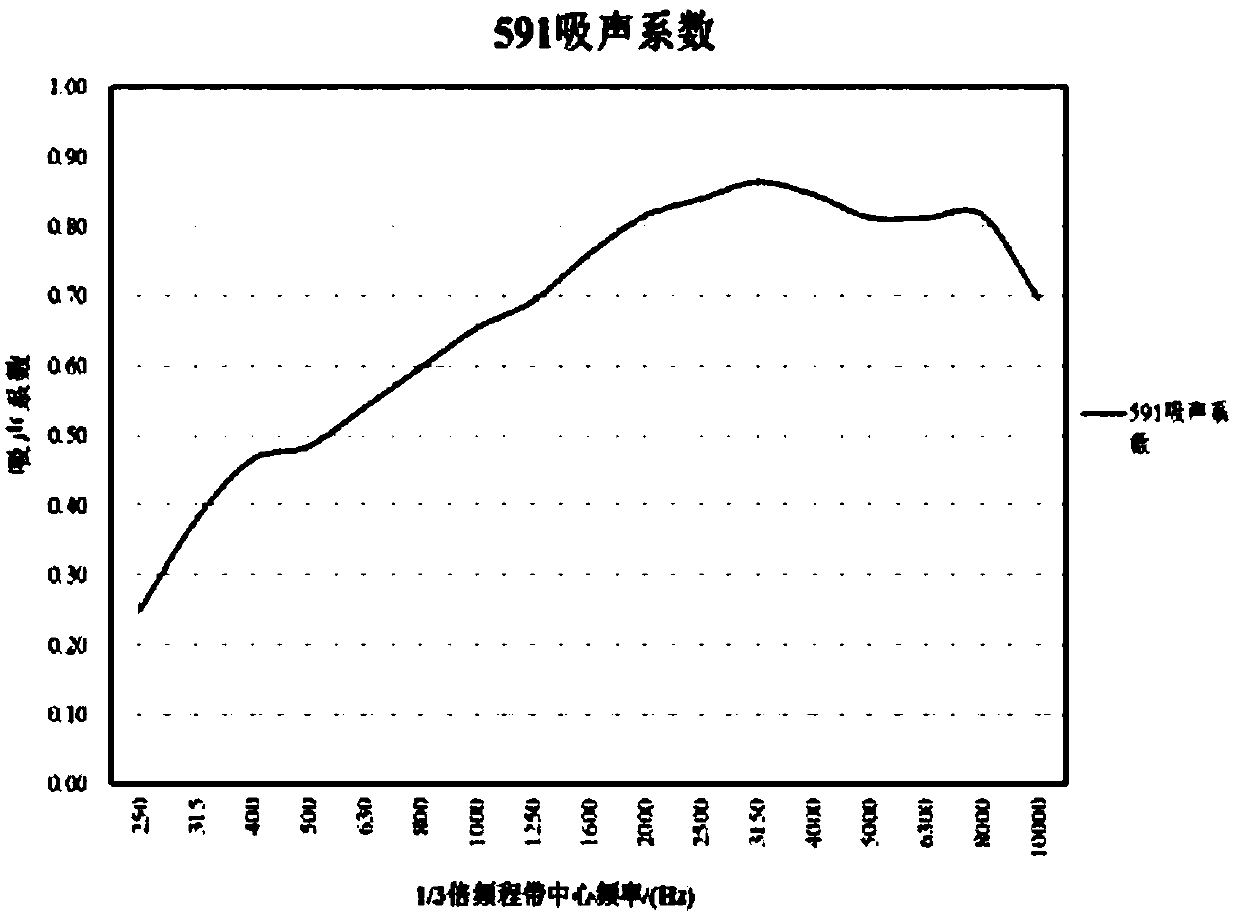

[0048] Produce Dongfeng Nissan 591 car carpet (gray), its specification is: 2100mm×1650mm, its production method is as follows:

[0049] a. A composite fiber material composed of PET fluff layer, PET-P layer, low-melting point PET layer and PET coating is selected, and the weight of the composite fiber material is 1550g / m 2 , the thickness of the composite fiber material is 12mm, a piece of EVA heavy coating material is placed on the PET coating of the composite fiber material, and the weight of the EVA heavy coating material is 2000g / m 2 , the thickness of EVA heavy coating material is 2mm, obtains carpet substrate;

[0050] b. Put the carpet substrate into the oven for heating. When heating, the temperature of the upper oven is controlled at 320~360°C, the temperature of the lower oven is controlled at 250°C, and the drying time is controlled at 80 seconds;

[0051] c. Put the heated carpet base material between the upper mold and the lower mold of the compression molding mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com