Numerically-controlled machine tool PLC control method capable of prolonging service life of machine tool spindle

A technology of machine tool spindle and CNC machine tools, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of easy burnout, affecting machining accuracy, and high maintenance cost of CNC machine tools, avoiding burnout and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

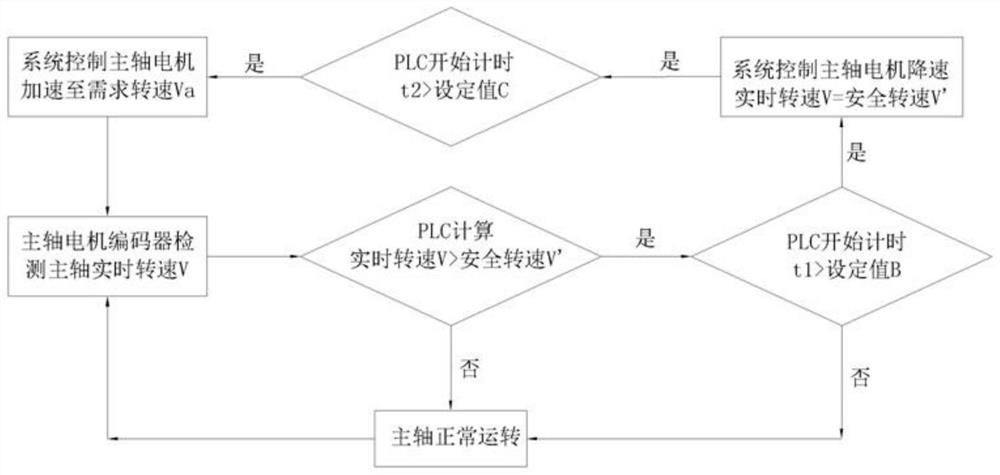

Image

Examples

Embodiment 1

[0023] Taking the BT40(150)HSK63 CNC machine tool as an example, it is divided into the following four situations

[0024] 1. When the maximum spindle speed is 10000RPM, the safe spindle speed v' is determined to be 6000RPM, the preset time B is 1 hour, and the preset time C is 30 minutes; when the CNC machine tool is running, when the spindle is running at a higher speed of 8000-10000RPM After running for a preset time B=1 hour, the PLC control system of the machine tool controls the spindle motor to slow down and controls the spindle to run at a speed less than or equal to the safe spindle speed v'=6000RPM for a preset time C=30 minutes, and then the PLC control system controls the spindle motor to increase speed, the spindle continues to run at a speed above 6000RPM, and this cycle;

[0025] 2. When the maximum spindle speed is 12000RPM, determine the safe spindle speed v' to be 10000PM, the preset time B to be 1 hour, and the preset time C to be 30 minutes; when the CNC ma...

Embodiment 2

[0029] Taking the BT50 vertical machining center as an example, there are two situations as follows

[0030] 1. When the maximum spindle speed is 6000RPM, determine that the safe spindle speed v' is 4500RPM, the preset time B is 15 minutes, and the preset time C is 30 minutes; After running for a preset time B=15 minutes, the PLC control system of the machine tool controls the spindle motor to slow down and controls the spindle to run at a speed less than or equal to the safe spindle speed v'=4500RPM for a preset time C=30 minutes, and then the PLC control system controls the spindle motor to increase speed, the spindle continues to run at a speed above 4500RPM, and this cycle;

[0031] 2. When the maximum spindle speed is 10000RPM, determine the safe spindle speed v' to be 8000RPM, the preset time B to be 15 minutes, and the preset time C to be 30 minutes; After running for 15 minutes, the PLC control system controls the spindle motor to slow down and controls the spindle to...

Embodiment 3

[0033] Take the BT50 horizontal machining center and the BT50 belt machine tool as examples, the maximum spindle speed of the two machine tools is 6000RPM, the safe spindle speed v' is set to 4500RPM and the preset time B is 15 minutes, and time C is 30 minutes ;When the machine tool is running, when the spindle runs continuously at a high speed of 4500-6000RPM for 15 minutes, the PLC control system controls the spindle motor to slow down to a spindle speed of 4500RPM, and controls the spindle to run at a speed not higher than 4500RPM for more than 30 minutes. Then the PLC control system controls the spindle to run continuously at a speed exceeding 4500RPM, and this cycle continues.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com