Cement rotary kiln power consumption prediction method based on convolution-gating recurrent neural network

A technology of cyclic neural network and cement rotary kiln, which is applied in the field of power consumption prediction of cement rotary kiln, can solve the problems of multi-variable cement firing, difficult to establish mechanism model, time-varying time delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

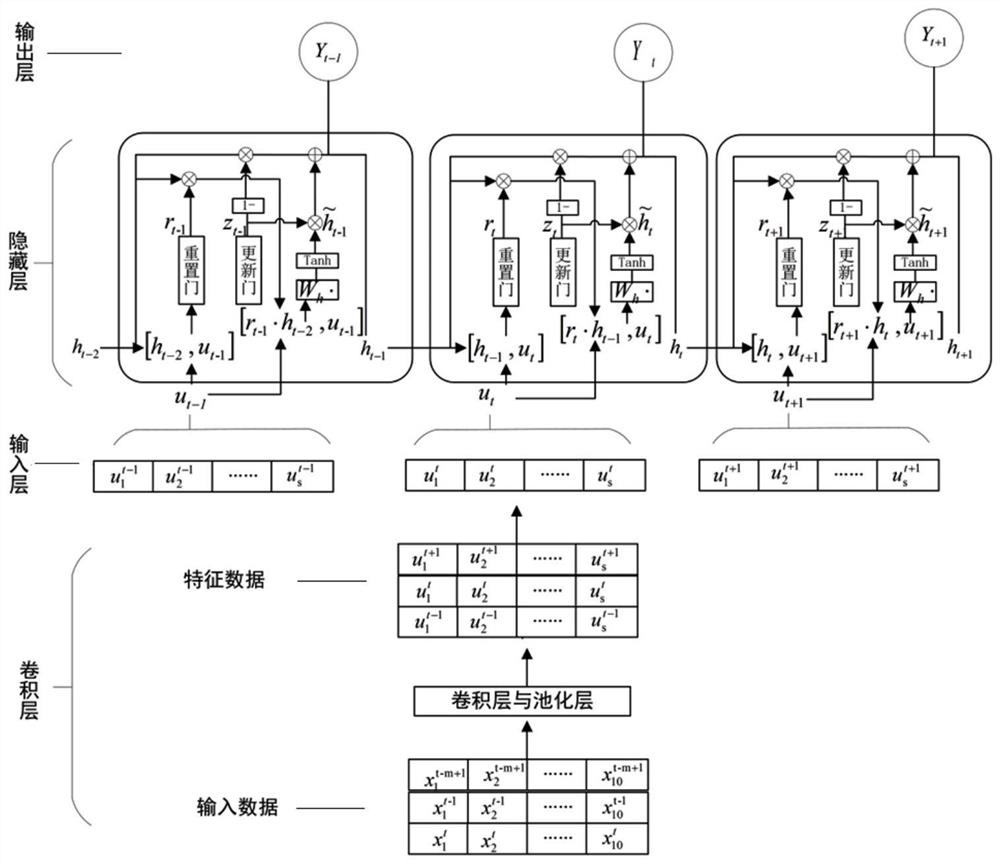

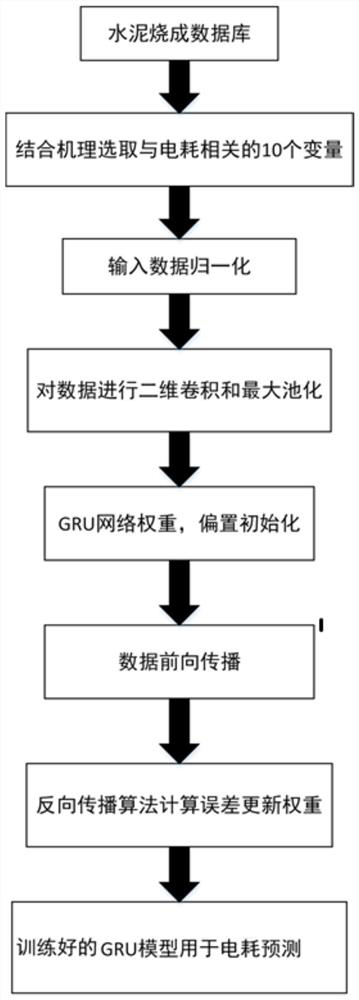

[0067] The present invention is aimed at the characteristics of the complexity, randomness and dynamic time-lag of the cement firing process, it is difficult to use traditional mathematical methods to establish an accurate power consumption prediction model, and the existing research methods in this technical field have their own limitations It is difficult to solve the problem of time-varying time delay and coupling between variables. A method for predicting power consumption of cement rotary kiln based on gated recurrent neural network was developed.

[0068] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0069] Such as figure 1 As shown, a method for predicting power consumption of cement rotary kiln based on gated cyclic neural network includes the following steps:

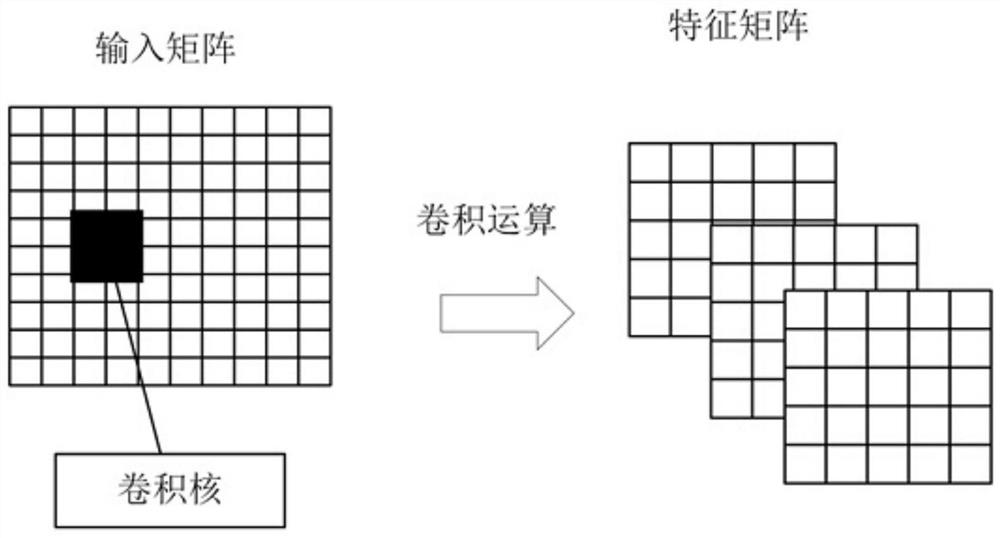

[0070] Step 1: Analyze the entire cement firing production process, select 10 input variables related to power consumption, and normalize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com