Safflower carthamus filament snap-in parallel harvesting robot

A picking robot and integrated technology, applied in picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as irregular distribution of flower balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

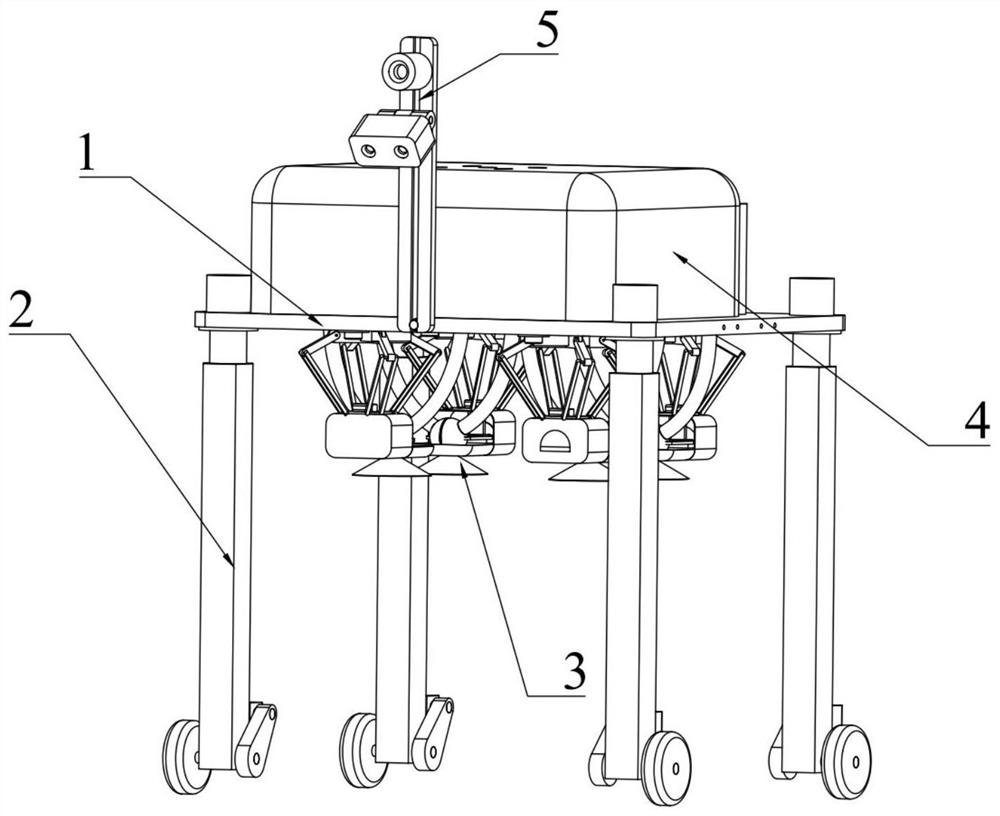

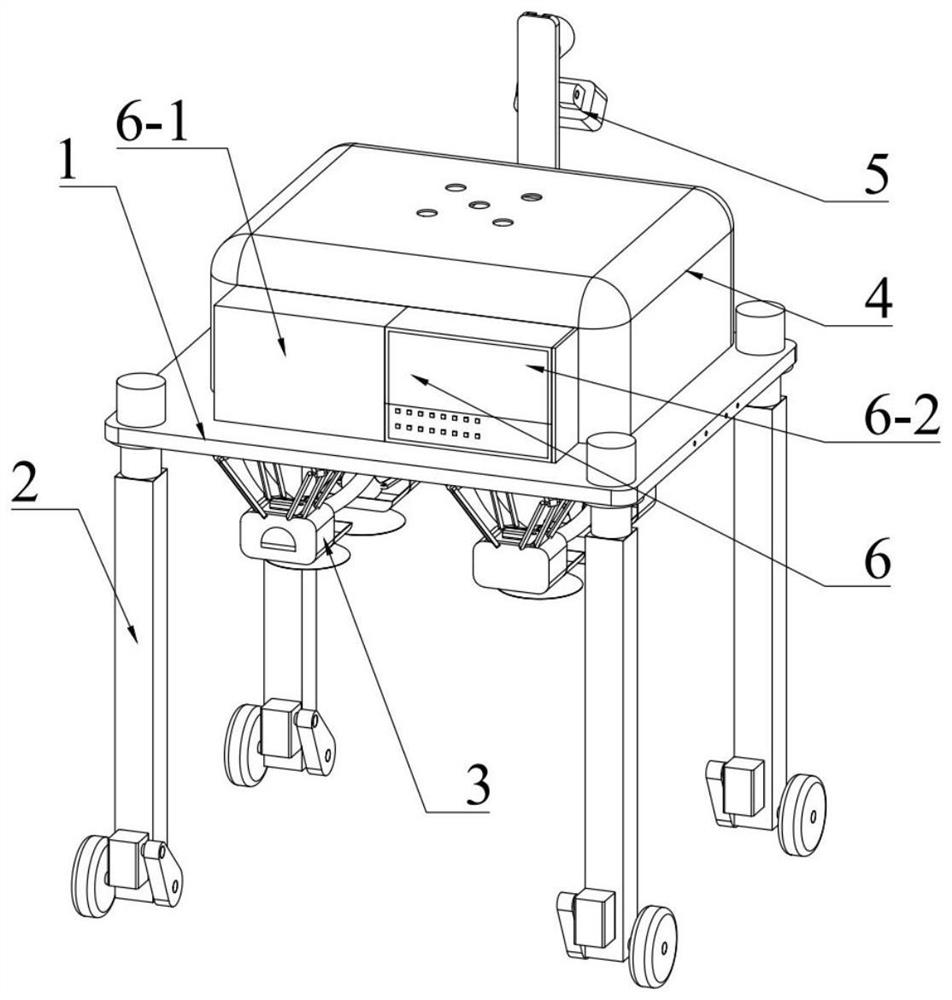

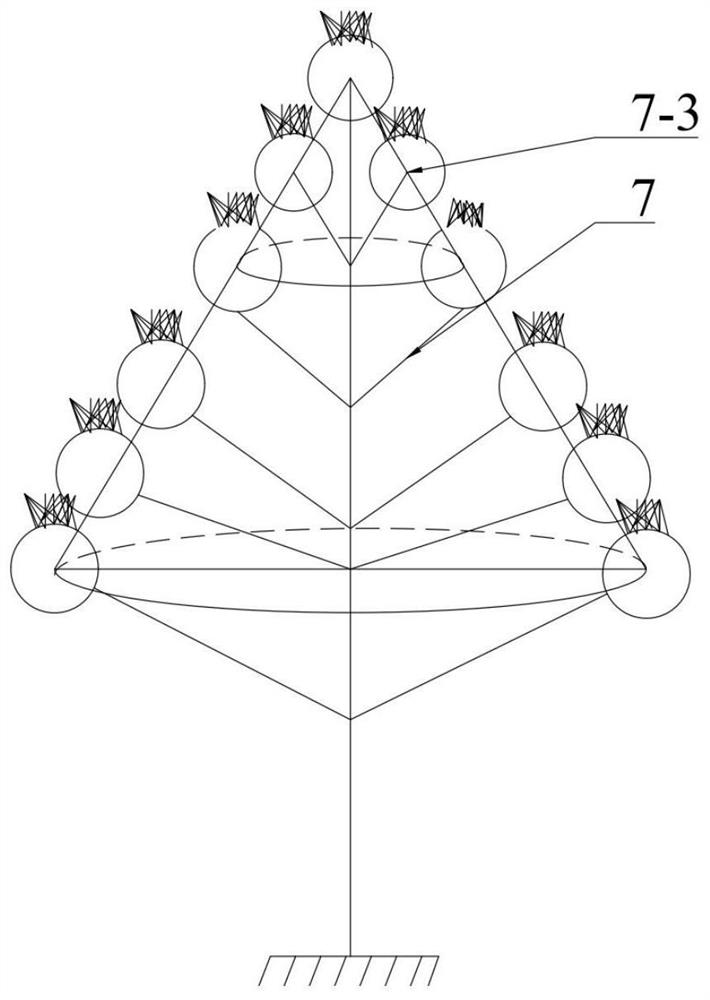

[0064] Such as Figure 1-2 As shown, a safflower filament occlusal parallel picking robot includes a mobile platform 1, an omnidirectional independent steering wheel 2, an occlusal parallel picking device 3, a filament collection box 4, a visual navigation recognition system 5 and an electric control system 6.

[0065] Four omni-directional independent steering wheels 2 are fixedly connected to the four corners of the horizontally arranged rectangular mobile platform 1 respectively, and have independent steering capabilities, so that the mobile platform 1 is located above the safflower plant during picking operations; the occlusal parallel picking Device 3 is affixed to the lower end surface of mobile platform 1; Described filigree collecting box 4 is positioned at the upper end surface of mobile platform 1; Described visual navigation recognition syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com