Gravure roller containerization storage bracket

A gravure roll and warehousing technology, which is applied to detachable cabinets, household appliances, furniture parts, etc., can solve the problems of high labor intensity and manpower, and achieve the effect of saving plant area and solving automatic logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

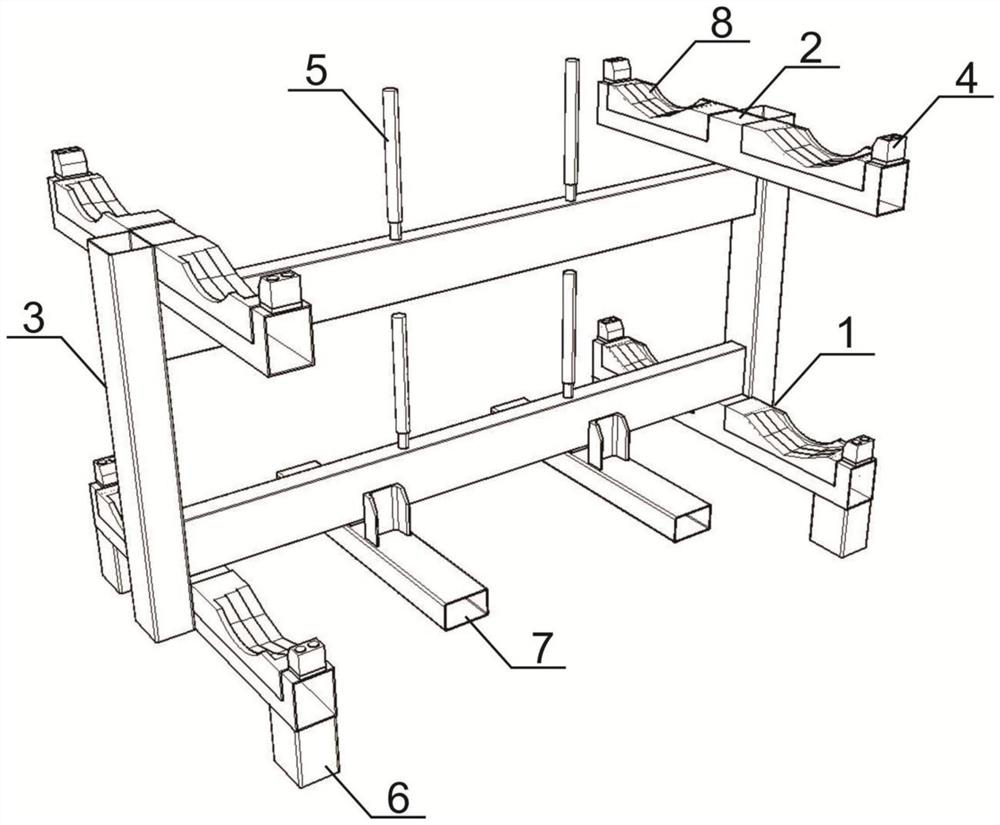

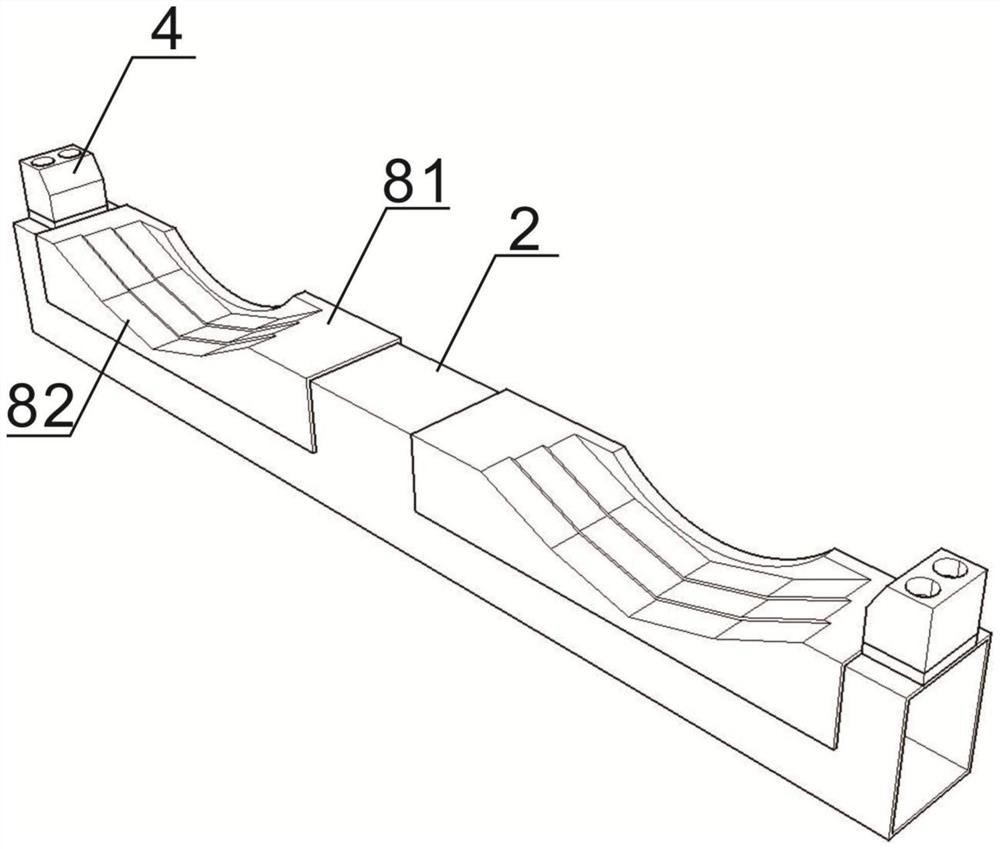

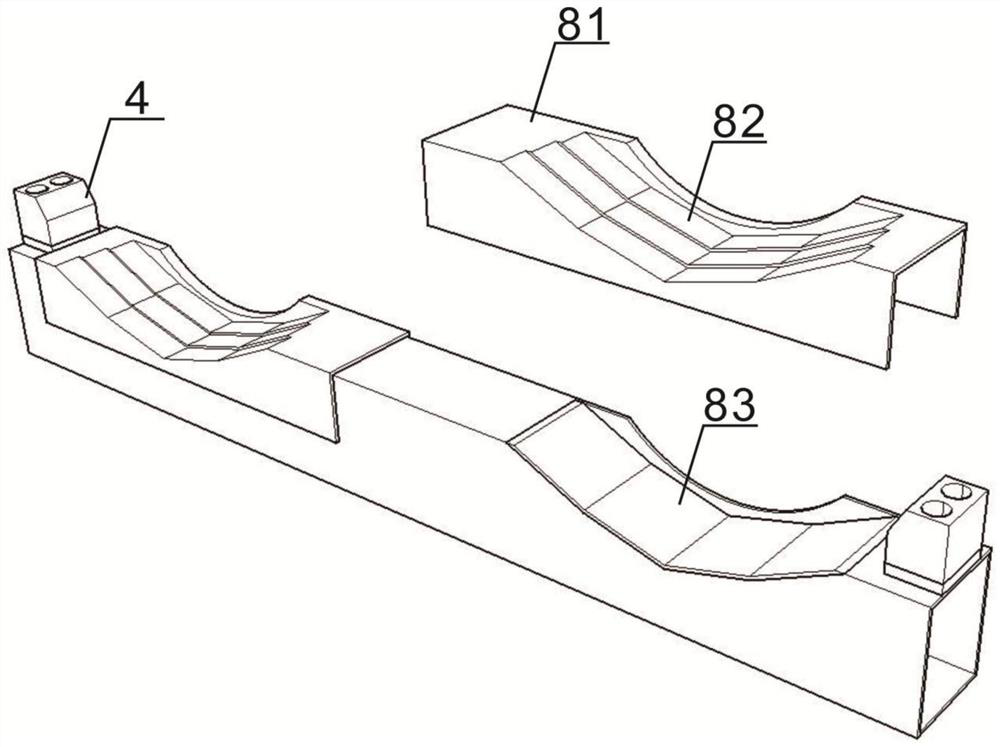

[0023] see Figure 1-6 , the present invention provides a technical solution: a gravure roller container storage bracket, including a lower shelf 1 and an upper shelf 2, the upper shelf 2 is located directly above the lower shelf 1, and is connected to the lower shelf 1 through a middle connecting shelf 3, so that The entire storage bracket is roughly in the shape of an "I"; two storage positions are respectively set on the lower shelf 1 and the upper shelf 2, and each storage position includes two symmetrically distributed end positioning parts 8; the end positioning The part 8 includes a support platform 82 with a low middle part and high sides and a strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com