In-vehicle shoe polisher and control method thereof

A shoe-shining machine, machine and motor technology, applied in computer control, program control, general control system and other directions, can solve the problem of unable to provide shoe-shining function, etc., achieve the effect of high degree of automation and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

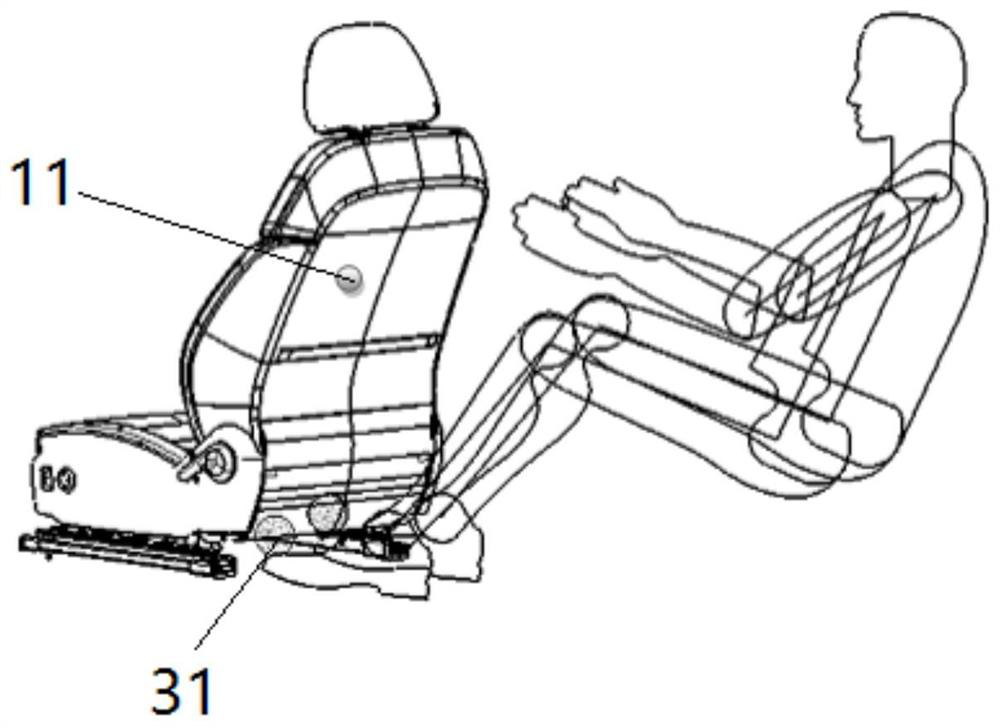

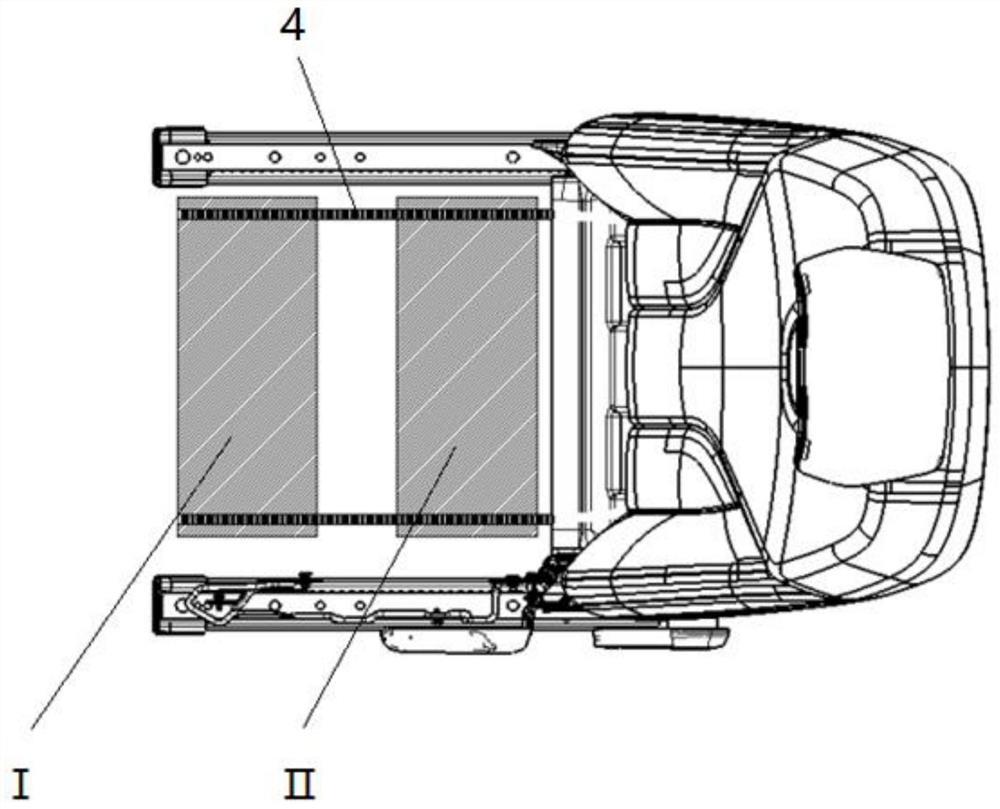

[0041] as follows figure 1 As shown, an in-vehicle shoe polisher is installed in the space below the front seat of the vehicle. The in-vehicle shoe polisher includes a total ECU module, a slide rail motor module, a shoe polisher module, a slide rail device 3, and a slide rail device Screwed to the vehicle body floor under the front seat of the vehicle and located inside the seat slide rail, such as figure 2 As shown; the shoe polisher module and the slide rail motor module are respectively screwed on the slide rail device; the main ECU module communicates with the slide rail motor module and the shoe polisher module through the CAN bus, and the main ECU module controls the slide rail motor module to drive the rubbing The shoe machine module moves along the slide rail device, and the main ECU module controls the shoe polisher module at the same time.

[0042] The shoe polisher module includes a shoe polisher ECU and a shoe polisher assembly. The shoe polisher ECU is connected to t...

Embodiment 2

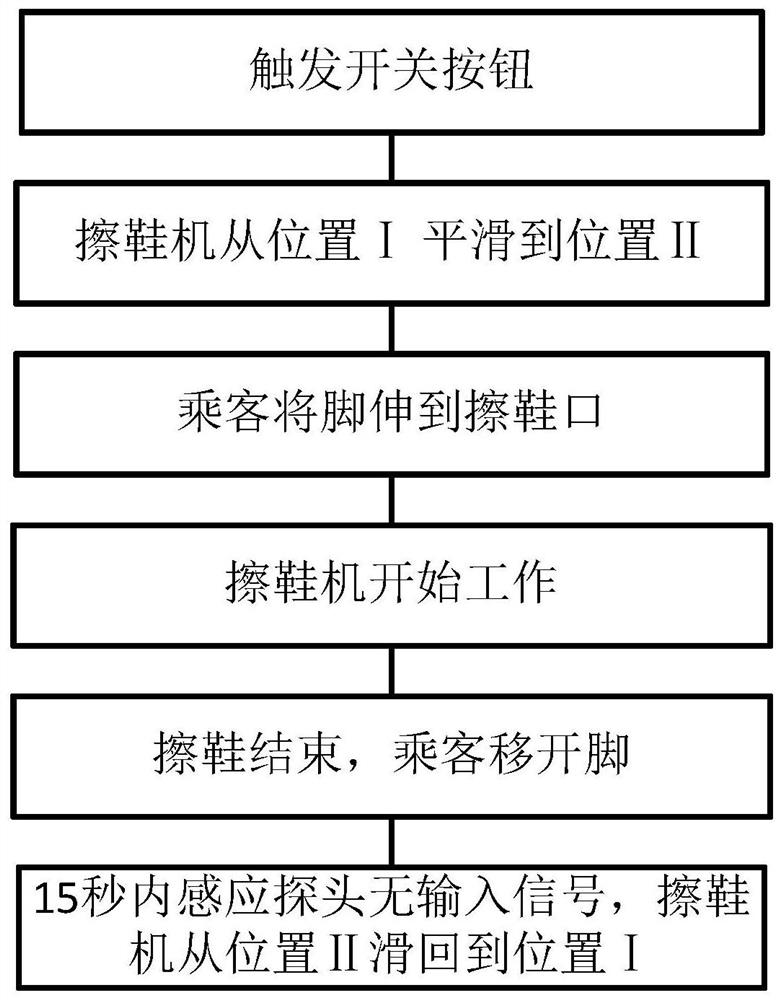

[0052] A control method of shoe polisher in car:

[0053] When the passenger triggers the shoe polisher switch on the back of the front seat, the shoe polisher switch transmits the signal to the main ECU through the CAN bus;

[0054] The main ECU transmits signals to the slide rail motor ECU through the CAN bus;

[0055] After receiving the signal, the slide rail motor ECU sends a command to the slide rail motor, and the slide rail motor drives the shoe polisher to slide along the track from position I at the front of the seat to position II at the rear of the seat.

[0056] Passengers stretch their feet to the shoe polisher port, and the infrared sensor located at the shoe polisher port transmits the signal to the main ECU after detecting a signal input;

[0057] The main ECU transmits a signal to the shoe polisher ECU through the CAN bus, and the shoe polisher ECU instructs the shoe polisher motor to start the shoe polish work.

[0058] After the shoe shine, the passenger retracts his ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com