Feeding mechanism for vehicle cold stamping and use method of feeding mechanism

A technology of feeding mechanism and cold stamping, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of raw material deviation, jammed conveyor belt, damaged conveyor belt, etc., to prevent deviation , the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

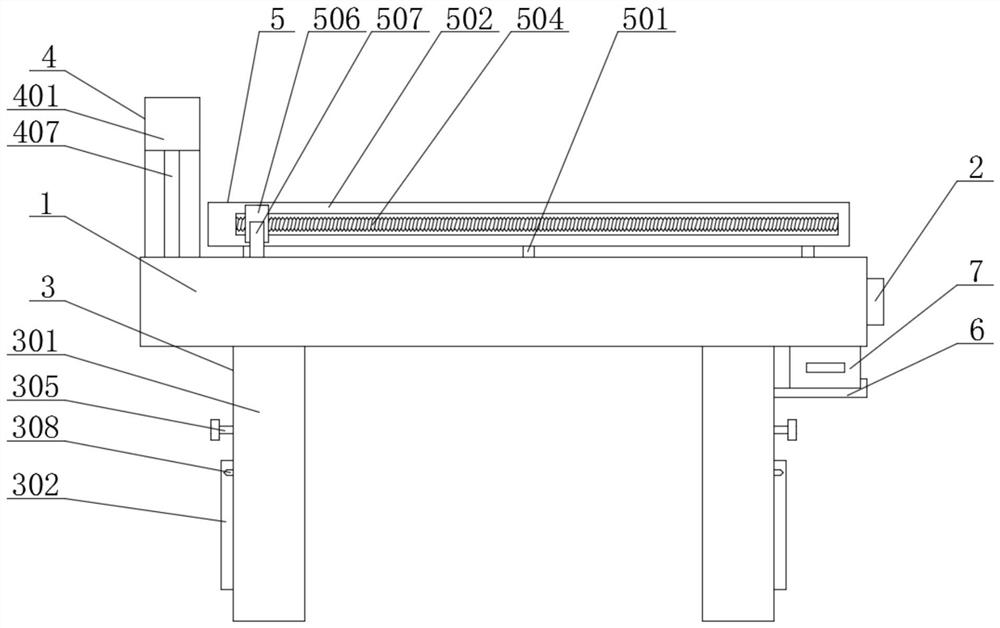

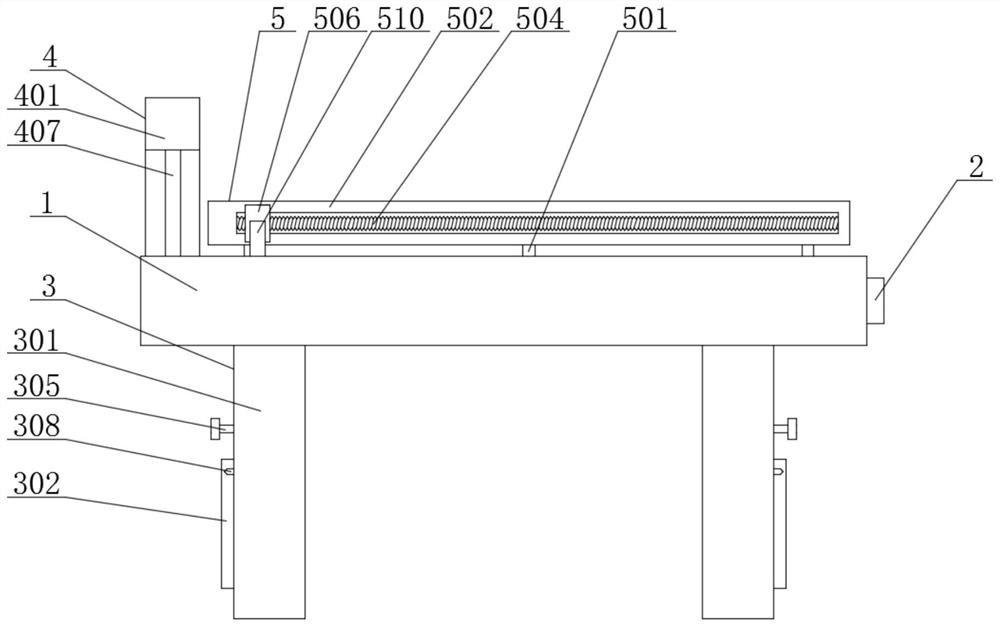

[0032] see figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution:

[0033] A feeding mechanism for cold stamping of automobiles, including a support plate 1, a lifting device 3, a limit device 4 and a cleaning device 5, a conveyor belt 8 is provided on the support plate 1, and a controller 2 is fixedly connected to the right end of the support plate 1 , the lifting device 3 includes a first leg 301 and a scale 302, the first leg 301 is fixedly connected to the support plate 1, the scale 302 is fixedly connected to the first leg 301, this arrangement can adjust the height of the support plate 1 To be more precise, the inner side of the top surface of the first leg 301 is rotationally connected with the first bevel gear 303, the outer side of the first bevel gear 303 is meshed with the second bevel gear 304, and the outer side of the second bevel gear 304 is fixedly connected with the first ...

Embodiment 2

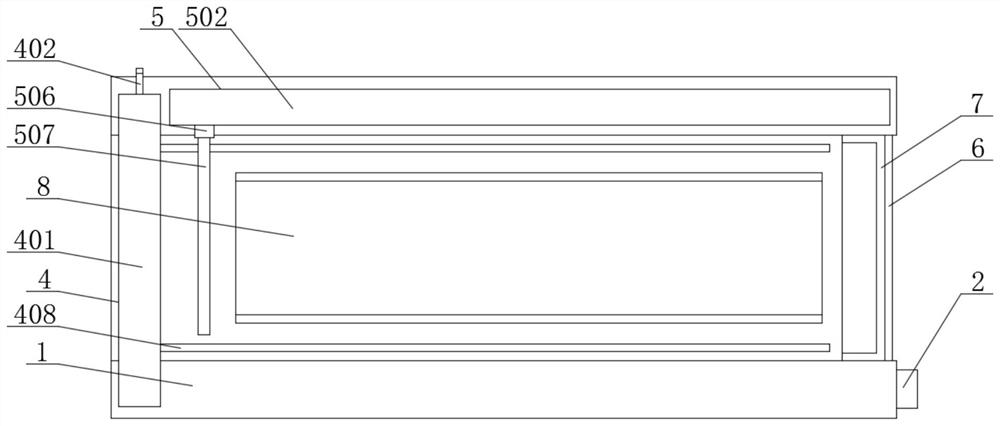

[0037] see image 3 , Figure 4 , Figure 5 and Figure 9 , the present invention provides a technical solution:

[0038] A feeding mechanism for cold stamping of automobiles, comprising a support plate 1, a lifting device 3, a limit device 4 and a cleaning device 5, the support plate 1 is provided with a conveyor belt 8, and the right end surface of the support plate 1 is fixedly connected There is a controller 2, the lifting device 3 includes a first leg 301 and a scale 302, the first leg 301 is fixedly connected to the support plate 1, and the scale 302 is fixedly connected to the first leg 301, which This setting can adjust the height of the support plate 1 more precisely, the inner side of the top end of the first leg 301 is rotatably connected with the first bevel gear 303, and the outer side of the first bevel gear 303 is meshed with the second bevel gear 304, so The outer side of the second bevel gear 304 is fixedly connected with a first handle 305, the first hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com