CNC machine tool rapid tool setting device

A technology of CNC machine tools and tool setting devices, which is applied to automatic control devices, feeding devices, metal processing machinery parts, etc., can solve the problems of troublesome operation, affecting production progress, low work efficiency, etc. The effect of preventing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

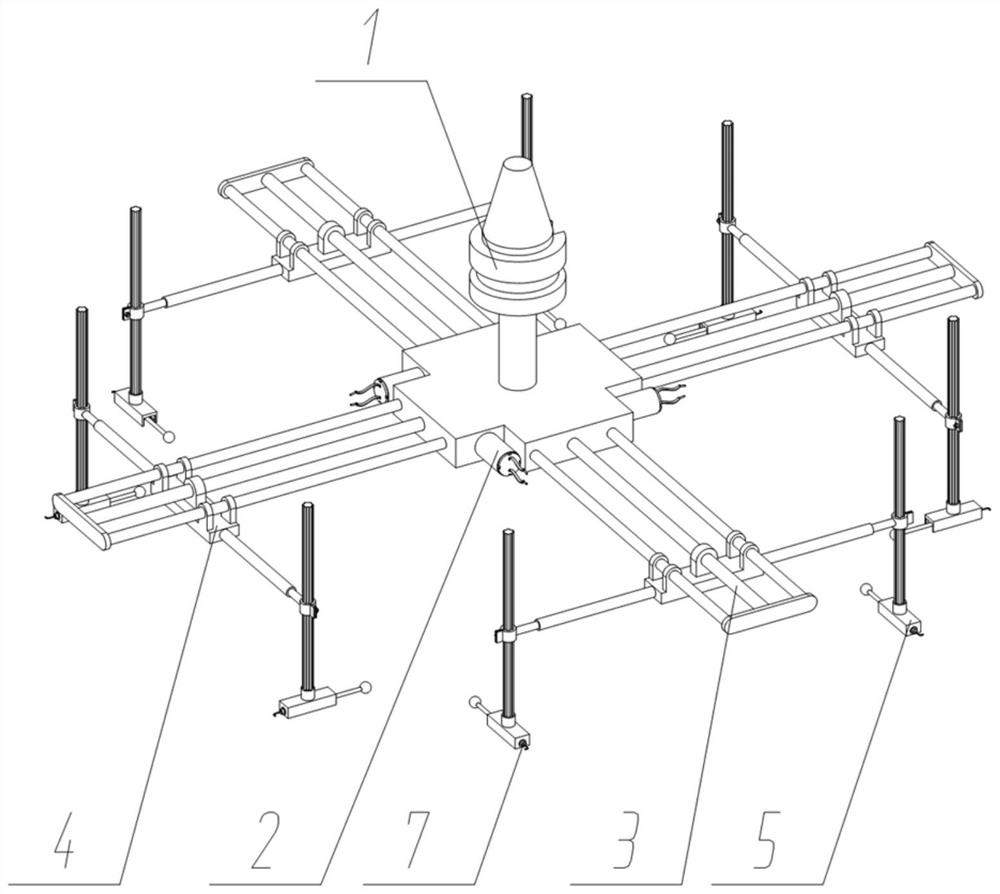

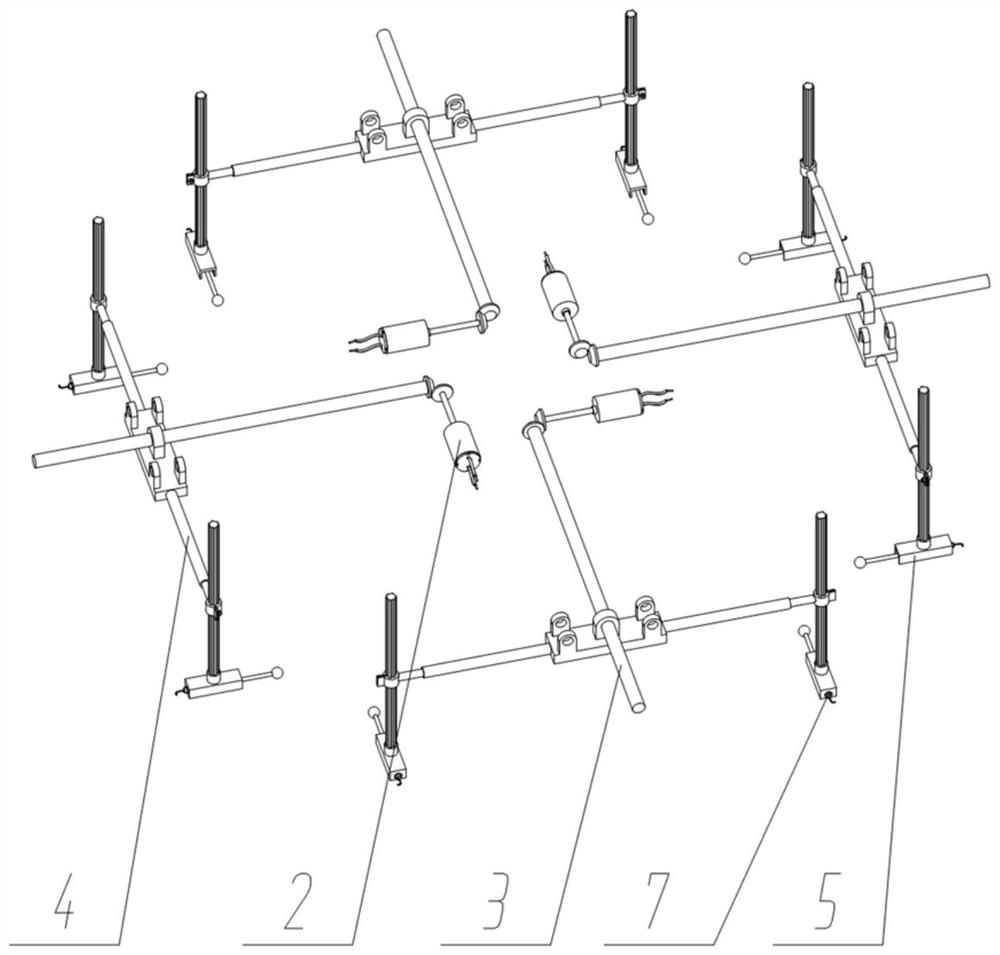

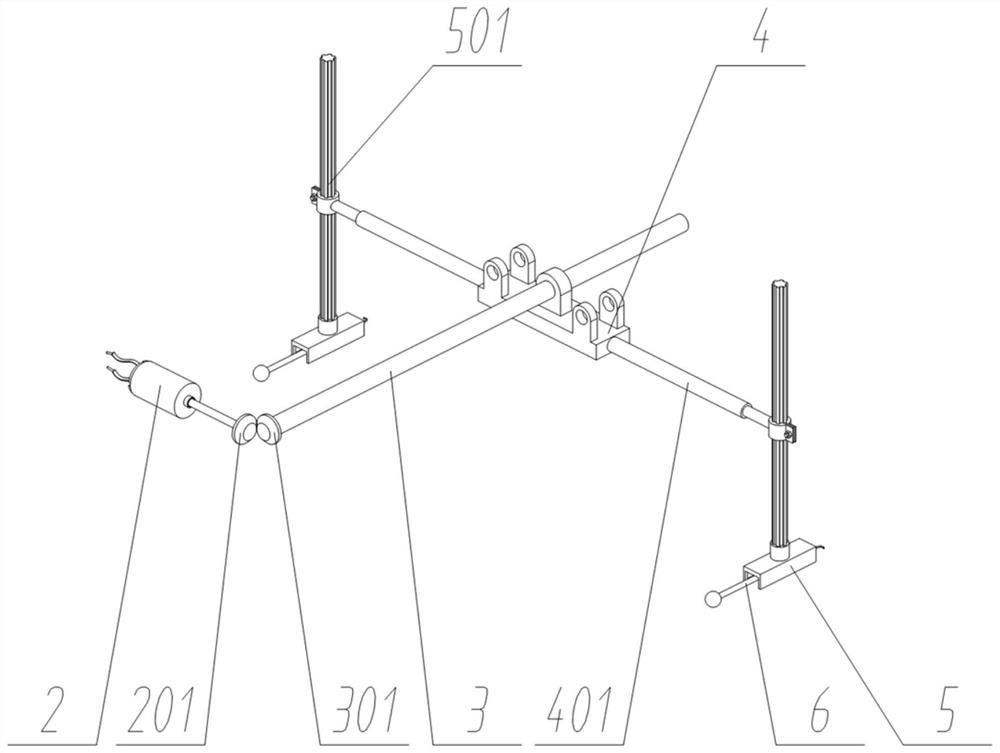

[0028] see Figure 1 to Figure 9 , a kind of embodiment that the present invention provides: CNC numerical control machine tool fast tool setting device, comprises mounting part 1; The lower circumferential array of mounting part 1 is slidably connected with four sets of sliding parts 4; The lower circumferential array of mounting part 1 is fixedly connected with four A group of power devices 2; four sets of sliding drive parts 3 are connected to the lower circumferential array of the mounting part 1; a group of lifting parts 5 are vertically slidingly connected to the left and right sides of each group of sliding parts 4; the bottom of the lifting part 5 is slidingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com