Detergent box assembly and washing machine

A detergent box and washing machine technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problem of residual washing powder powder, etc., and achieve the effect of improving the dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

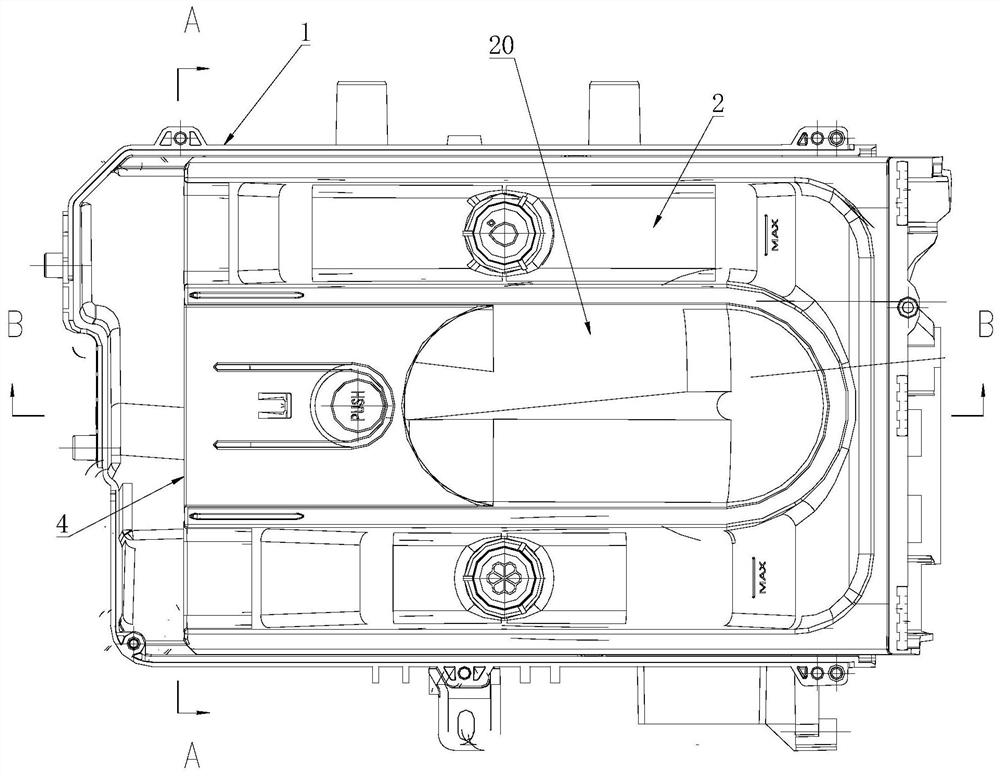

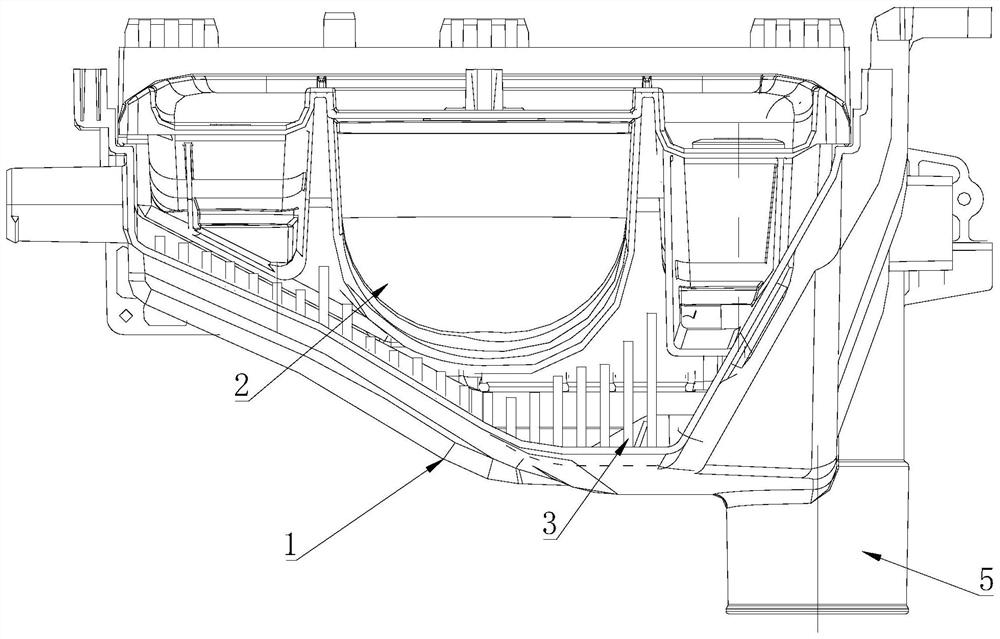

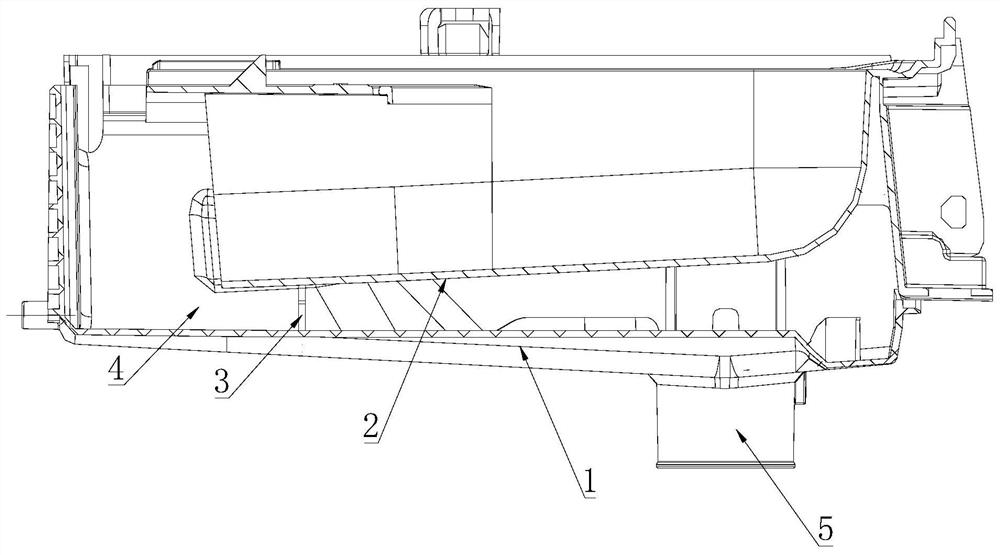

[0037] Such as Figure 1 to Figure 3 As shown, in the embodiment of the present invention, an intercepting device is provided between the bottom wall of the water inlet box 1 and the bottom wall of the detergent box 2 to divert and block the water flow through, so as to intercept the block-shaped detergent additives wrapped in the water flow. 3. The retaining device 3 includes at least one row of water-retaining ribs, a water flow channel for water flow is formed between adjacent water-retaining ribs, and the side of the water-retaining ribs impacted by the water flow blocks block-shaped detergent additives.

[0038] In this embodiment, the arrangement direction of the water retaining ribs is perpendicular to the communication direction of the water inlet 4 and the water outlet 5, please refer to figure 2 with image 3 , which is a preferred embodiment of the present invention, figure 2 with image 3 The retaining device 3 includes a row of retaining ribs.

[0039] In this...

Embodiment 2

[0046] Such as Figure 4 As shown, the difference between the embodiment of the present invention and the first embodiment is that the retaining device 3 is a plate-shaped structure, the baffle structure is perpendicular to the direction of water flow, and the plate-shaped structure is provided with water-permeable holes for the washing liquid to pass through. The aperture of the hole is relatively small, which does not allow larger pieces of washing powder to pass through, and the side of the plate structure near the detergent box 2 is adapted to the shape of the detergent box 2 .

[0047] In this embodiment, the water permeable hole is in any shape such as a circle or a strip, or a combination of multiple shapes.

[0048] In this embodiment, the plate structure is fixedly connected with the detergent box 2 or the water inlet box 1; preferably, the plate structure is integrally designed with the water inlet box 1 or the detergent box 2; at least There is a gap for water flow...

Embodiment 3

[0051] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the retaining device 3 is a filter screen, the side wall of the water inlet box 1 and / or the bottom wall of the water inlet box 1 and / or the detergent box The bottom wall of 2 is provided with hook, and the peripheral hook of filter screen is hung on the hook place on the side wall and bottom wall of water inlet box 1.

[0052] In this embodiment, the filter screen is tensioned and installed in the water inlet box 1 perpendicular to the direction of water flow.

[0053] In this embodiment, the washing liquid will generate foam after passing through the filter, and the foam will enter the washing tub along with the washing liquid, so as to improve the washing efficiency and the cleaning ratio of clothes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com