A trolley three-stage pouring working method

A working method and technology of pouring method, which are applied to earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of small size of pouring nozzle, not considering the problem of concrete flow, precise control of difficult pouring amount, etc., so as to reduce redundancy. Effects of parts and volume, increased cleaning cycle time, reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

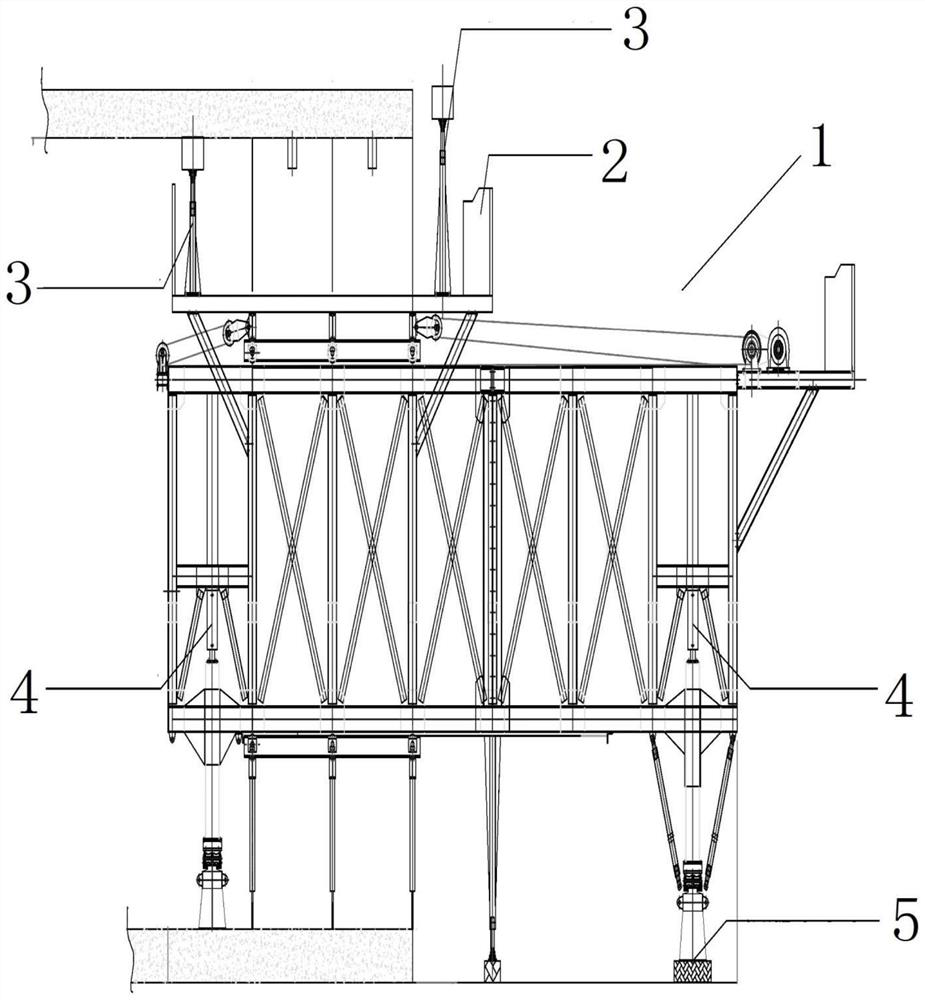

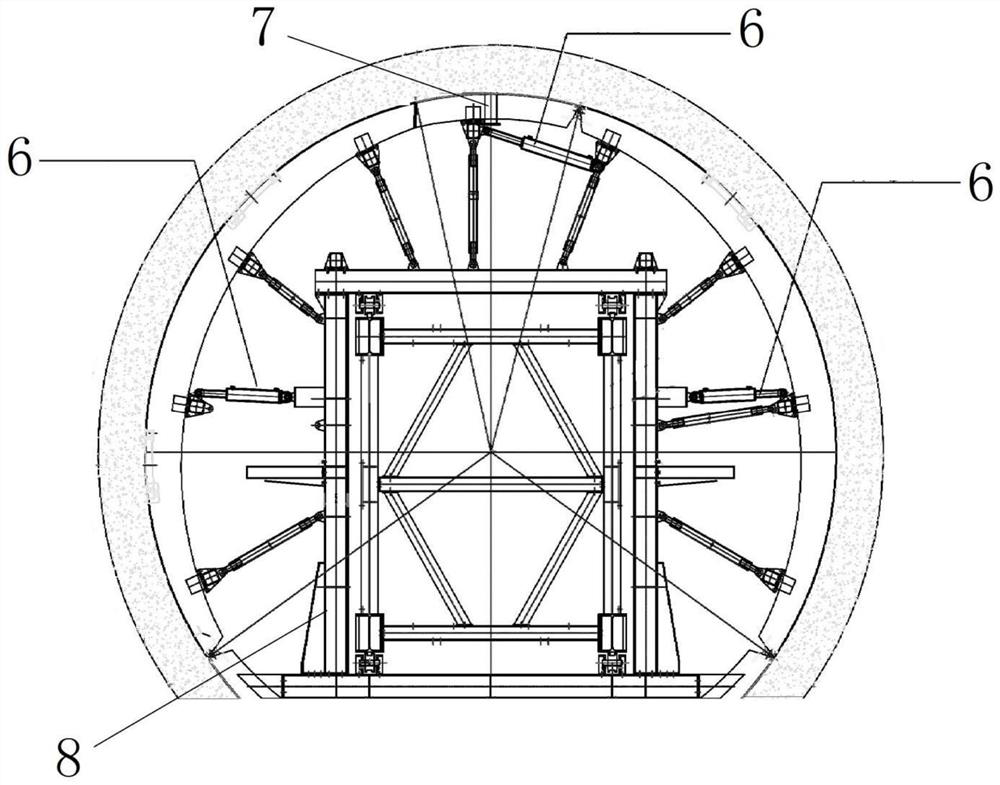

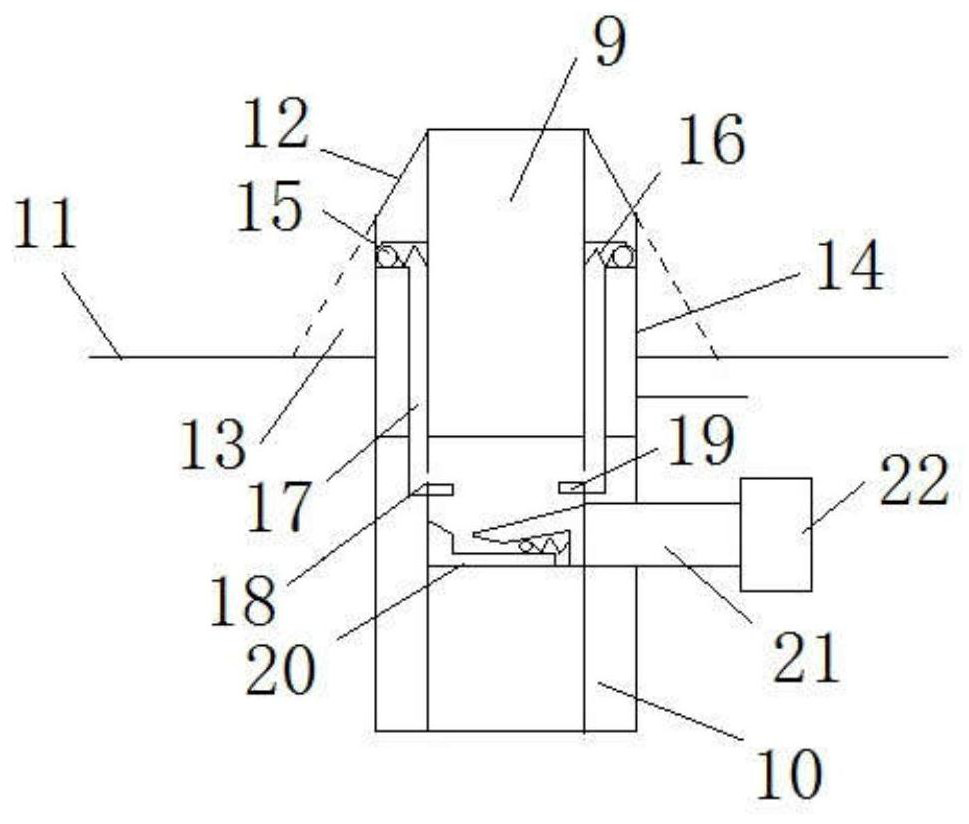

[0048] As shown in the figure: a three-stage pouring method for a trolley, the working method includes a trial pouring method, a three-stage pouring method, and a cleaning method; the trolley is a needle beam trolley, and the needle beam trolley includes: Hydraulic source, anti-floating jack, vertical oil cylinder, support, demoulding oil cylinder, concrete pouring assembly, trolley main body, control module; the concrete pouring assembly includes a pouring joint, a pouring valve, and the pouring joint includes a drainage surface, a lift High area, pressure relief element, pressure relief spring, pressure relief channel; the drainage surface guides the oblique flow of concrete so that a shielding area appears on the pouring surface, and the pressure relief channel includes a pouring joint section and a pouring valve section; the pouring A discharge port is provided at the end of the valve section, and the pouring valve includes a sealing plate, a valve plate, a valve stem, a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com