Heating surface embedded system applicable to mixed burning of lignite in various proportions in supercritical boilers

A supercritical boiler and embedded system technology, applied in the field of heating surface systems, can solve the problems of poor fuel flexibility, reduce the difficulty of manufacturing and assembly, facilitate refined design, and protect people's livelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

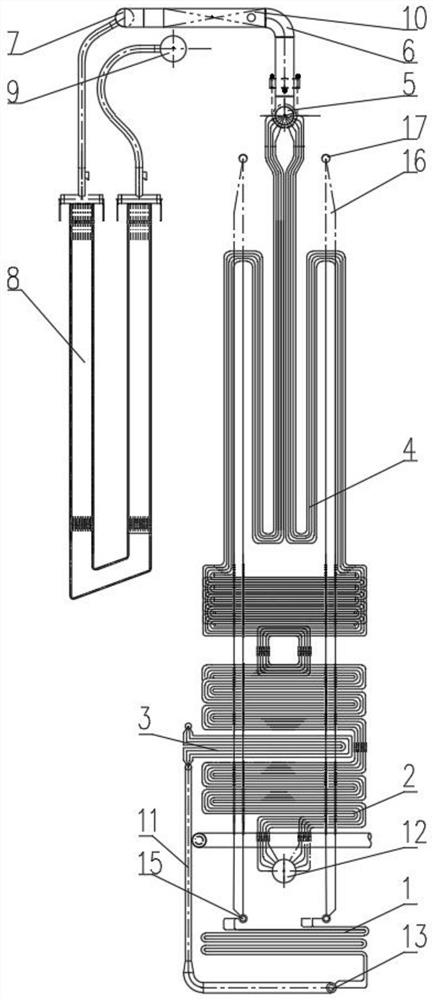

[0023] Specific implementation mode one: combine figure 1 Describe this embodiment, a heating surface embedded system that can adapt to the mixed combustion of lignite in various proportions of supercritical boilers in this embodiment, including a horizontal low-temperature reheater 2, an embedded economizer 3, and a vertical low-temperature reheater 4. Low re-export header 5, last re-entry header 7, final reheater 8, last re-export header 9, low re-entry header 12 and economizer inlet header 13, economizer The inlet header 13 is connected to the inlet of the embedded economizer 3 through the economizer pipeline 11, and the outlet of the embedded economizer 3 is connected to the distribution header of the water wall;

[0024] The low re-inlet header 12 is connected to the inlet of the horizontal low-temperature reheater 2, the outlet of the horizontal low-temperature reheater 2 is connected to the inlet of the vertical low-temperature reheater 4, and the outlet of the vertical...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 This embodiment is described, which is a heating surface embedded system that can adapt to the mixed combustion of various proportions of lignite in a supercritical boiler. The embedded economizer 3 is embedded and installed in the horizontal low-temperature reheater 2 .

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 Describe this embodiment, a heating surface embedded system that can adapt to the mixed combustion of lignite in various proportions of supercritical boilers in this embodiment, the inlet header 13 of the economizer is connected to the economizer 1, and the embedded economizer 3. Parallel connection with economizer 1 through economizer inlet header 13, economizer 1 is connected with hanging pipe inlet header 15, hanging pipe inlet header 15 is connected with hanging pipe outlet header 17 through hanging pipe 16 Connection, water enters the economizer inlet header 13 from the water supply pipe, and the water is divided into two paths in the economizer inlet header 13: one part enters the lower part of the economizer 1, enters the hanging pipe inlet header 15 after heating and It flows through the hanging pipe 16 and enters the outlet header 17 of the hanging pipe. The hanging pipe 16 is used for load-bearing and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com