Silicon carbide epitaxial growth device

A technology of epitaxial growth and silicon carbide, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of unstable flow control, reduced branch flow, complex structure, etc., and achieve the goal of improving equipment safety and control The effect of increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present application and not limit the scope of the present application. The implementation conditions adopted in the examples can be further adjusted as the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

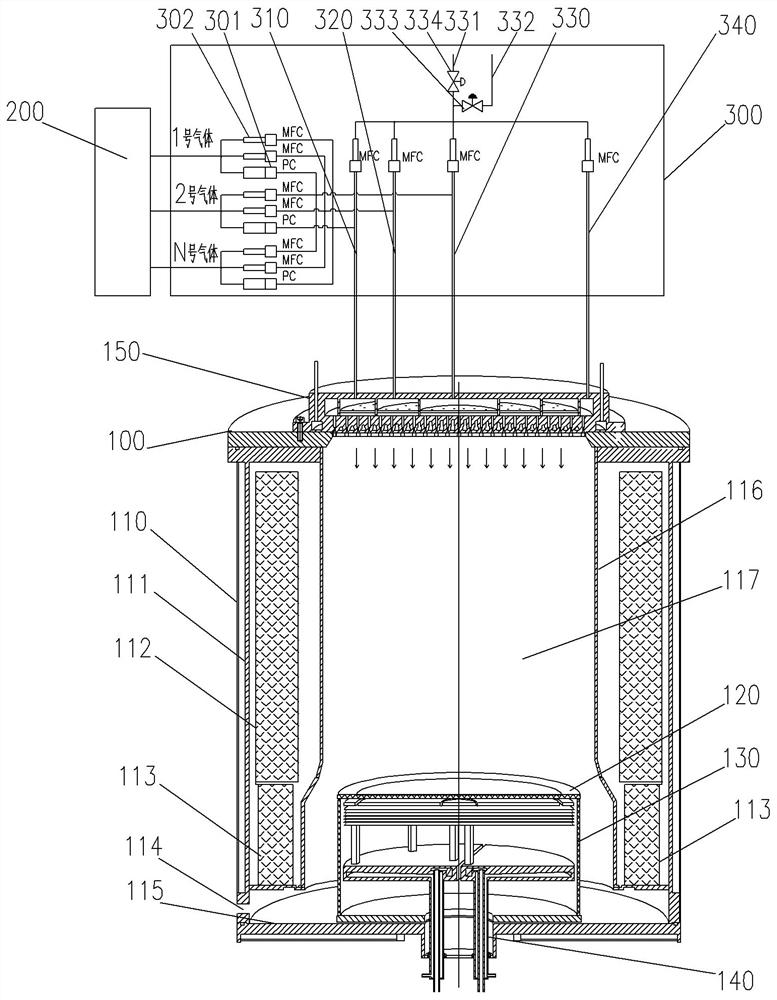

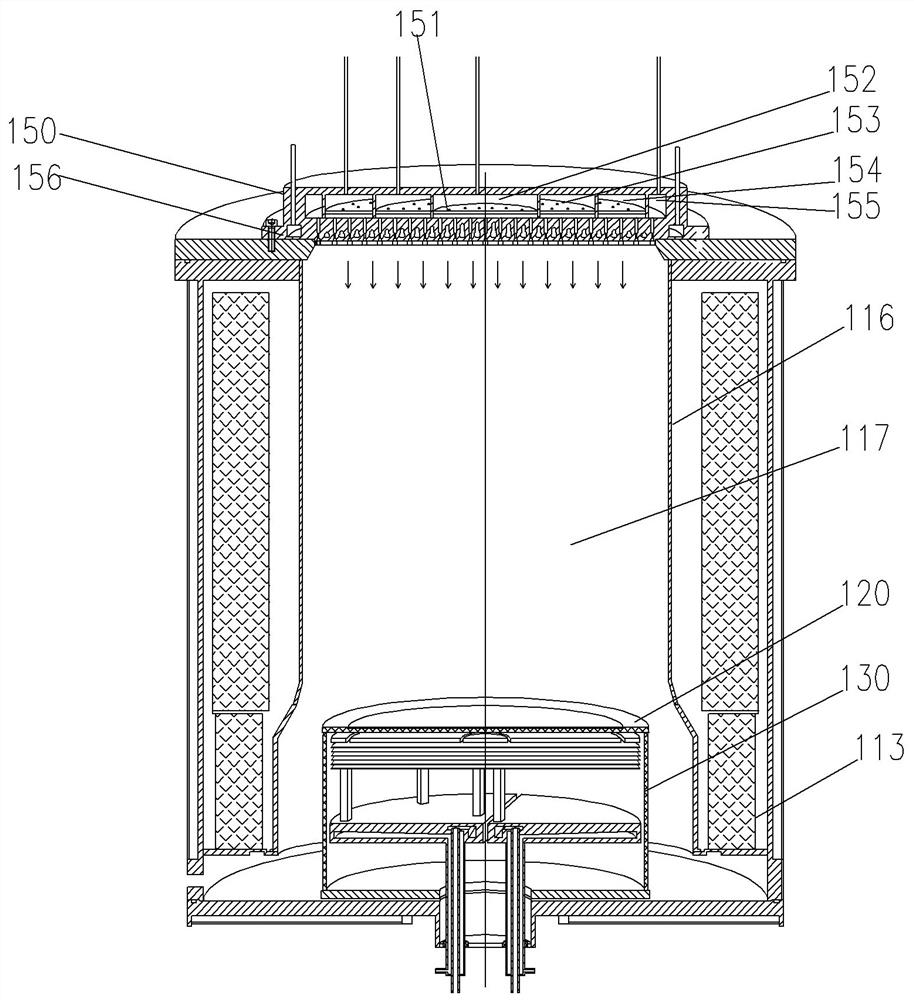

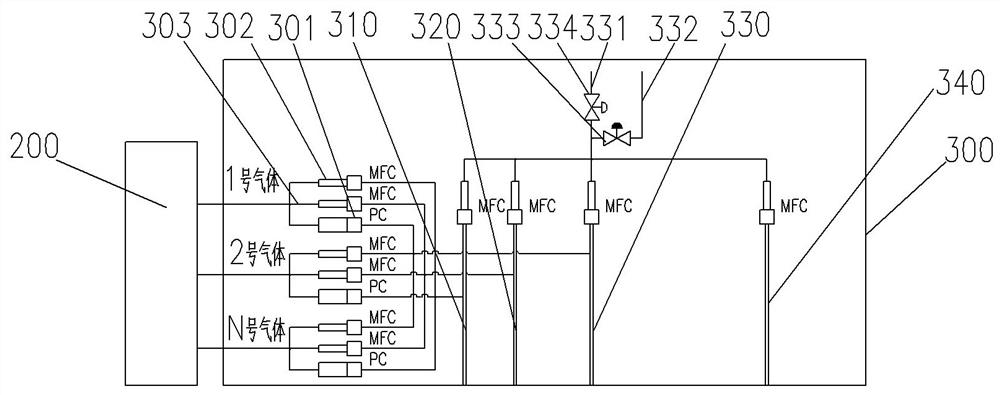

[0045] The present application proposes a silicon carbide epitaxial growth device, which includes: a reaction module, a multi-chamber shower head device is installed on the reaction module, and the multi-chamber shower head device is connected to a gas supply system, and the gas supply system includes : front-end module and back-end module, the front-end module is used to access the reaction gas, the output of the front-end module is connected to the back-end module, the gas path of the back-end module is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com