Polyurethane-based composition

A composition and polyurethane technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as low reactivity, limited mechanical properties, and extrusion difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

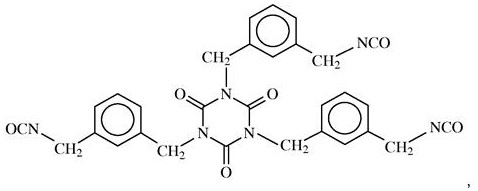

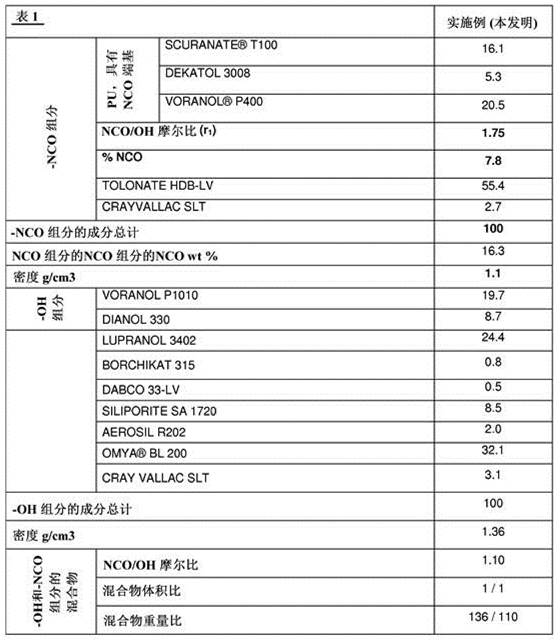

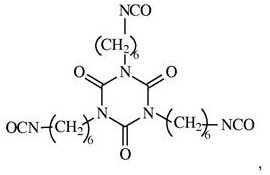

[0331] Embodiment 1:-Preparation of NCO component:

[0332] 1.A. Preparation of polyurethane (PU) with NCO end groups :

[0333] The polyurethanes PU with NCO end groups used in the following examples were prepared using the various ingredients given in Table 1 . The amount of one or more diisocyanates and one or more polyols used (expressed as weight percent of the commercial product relative to the weight of the -NCO component) corresponds to an NCO / OH molar ratio (r1) of about 1.75, as shown in the table 1.

[0334] One or more diisocyanates and one or more polyols are mixed in a reactor at a temperature T1 of 65°C to 80°C, maintaining constant stirring and under nitrogen. The temperature was controlled to not exceed 82°C.

[0335] The entire mixture is kept mixing at this temperature until the hydroxyl functionality of the polyol is completely consumed.

[0336] The progress of the reaction was monitored by measuring the content of NCO groups by back-titration of dic...

Embodiment 2

[0343] Embodiment 2: Preparation of -OH component

[0344] The various components constituting the -OH component were mixed in the ratios shown in Table 1 at a temperature ranging from 20°C to 80°C in a reactor kept under constant stirring and under nitrogen.

[0345] After homogenization of the mixture (approximately 3 hours), the content of OH groups in the -OH fraction was measured in mg KOH / gram of -OH fraction (mg KOH / g).

Embodiment 3

[0346] Embodiment 3: the preparation of adhesive composition

[0347] The -NCO component prepared in Example 1 and the -OH component prepared in Example 2 were mixed.

[0348] Mixing was performed using a 50 ml double cylinder at a temperature of about 23°C.

[0349]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com