Glass greenhouse system utilizing light guide shutter insulation board

A glass greenhouse and thermal insulation board technology, which is applied in the agricultural field, can solve the problems of restricting the thickness of the curtain, the large heat dissipation surface of the glass greenhouse, and increasing the heat conduction coefficient, so as to reduce the long-wave radiation heat loss, reduce the penetration heat loss, and improve the temperature control ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

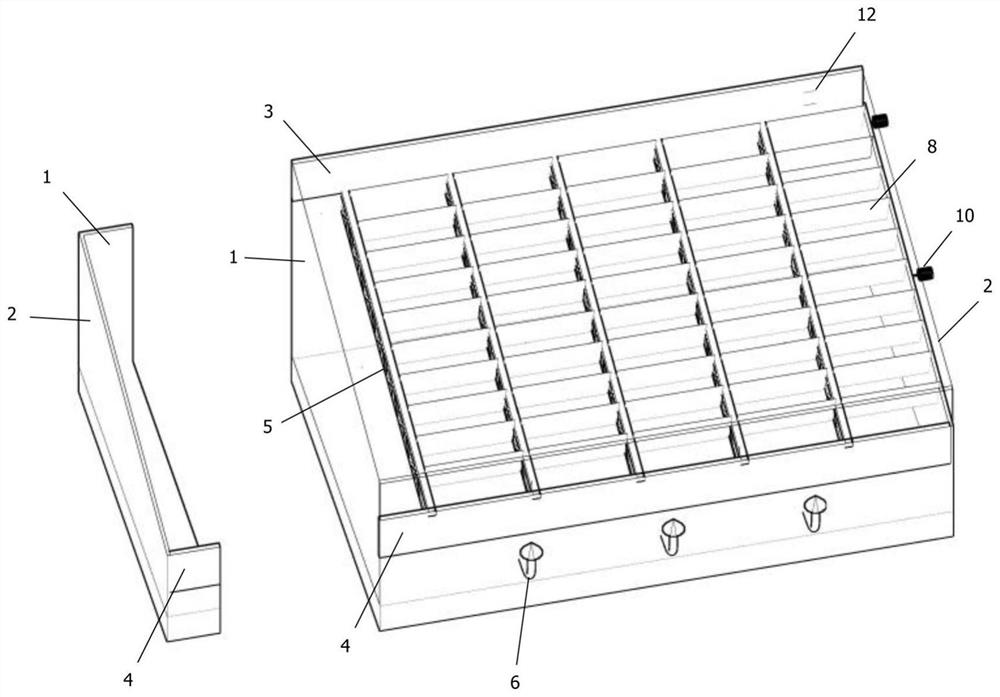

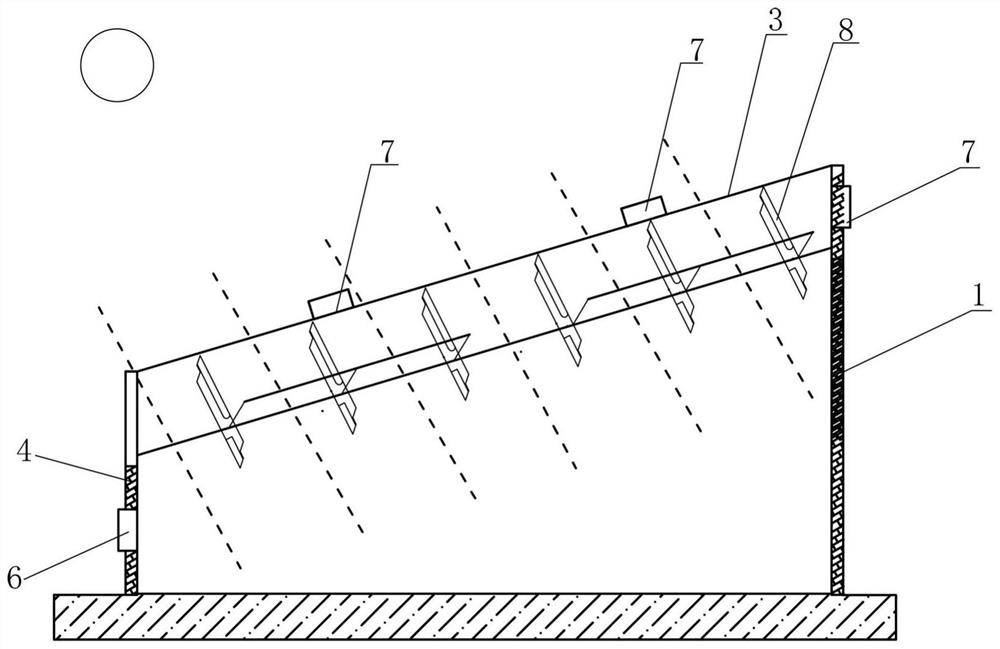

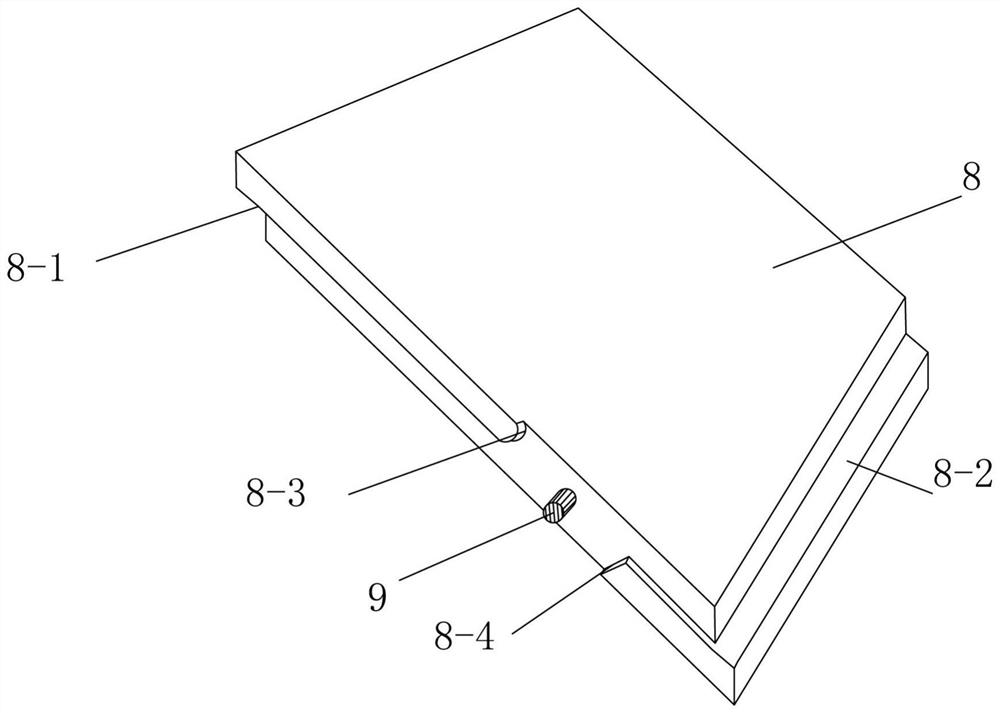

[0044] refer to figure 1 , figure 2 , the glass greenhouse system of the present invention comprises a thermal insulation north wall 1, a thermal insulation east and west gable wall 2, a single-slope glass daylighting ceiling 3 high in the north and low in the south, a glass daylighting south wall 4, a truss 5 carrying the glass ceiling, and trusses distributed in the greenhouse Pillar (not shown), ventilation air inlet 6, ventilation air exhaust outlet 7, the improvement that is done is: the louver type heat preservation, temperature regulation, the louver type heat preservation that useful insulation material rotatable light guide louver insulation board 8 is formed near the position of glass daylighting ceiling The inner ceiling of the light adjustment, the length of the light-guiding louver insulation boards 8 that make up the ceiling is in the east-west direction, and the light-guiding louver insulation boards 8 that are neatly arranged from the top of the slope to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com