Stirring device for barreled water barrel production

The technology of a stirring device and a water bucket is applied in the field of barreled water bucket processing and production equipment, which can solve the problems of clogging, no preheating effect, slow feeding, etc., and achieves the effect of maintaining heating action, novel structure, and accelerating feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

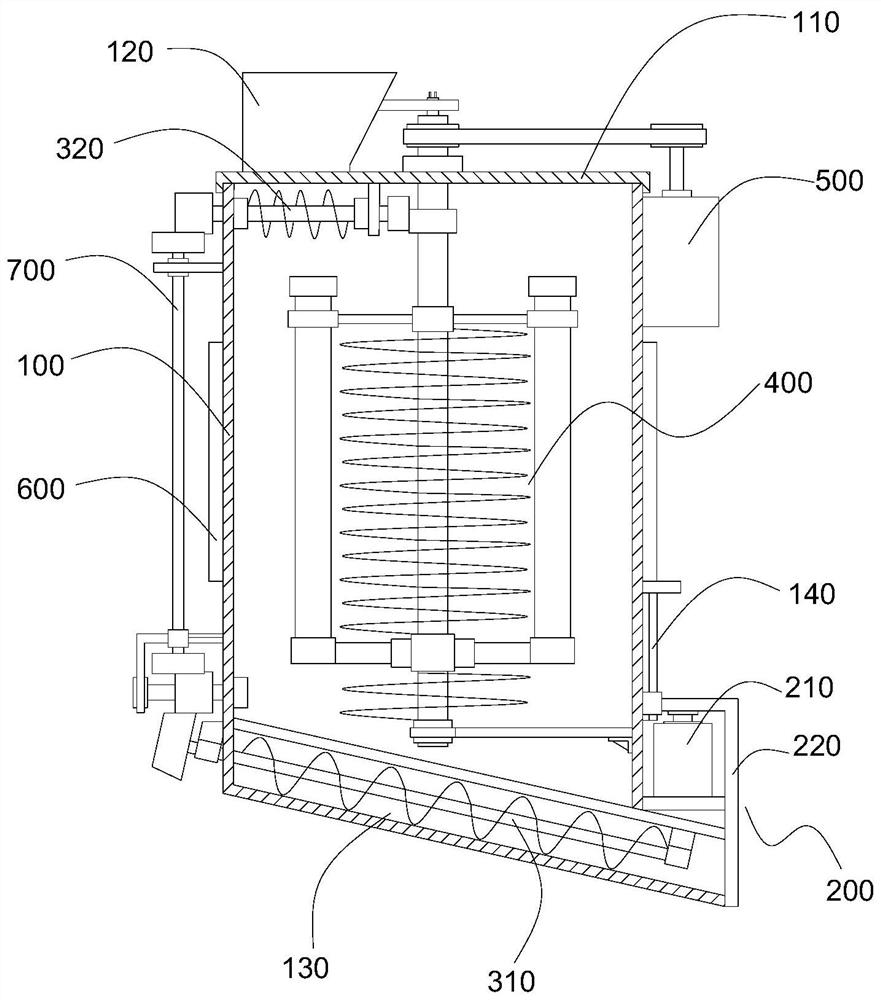

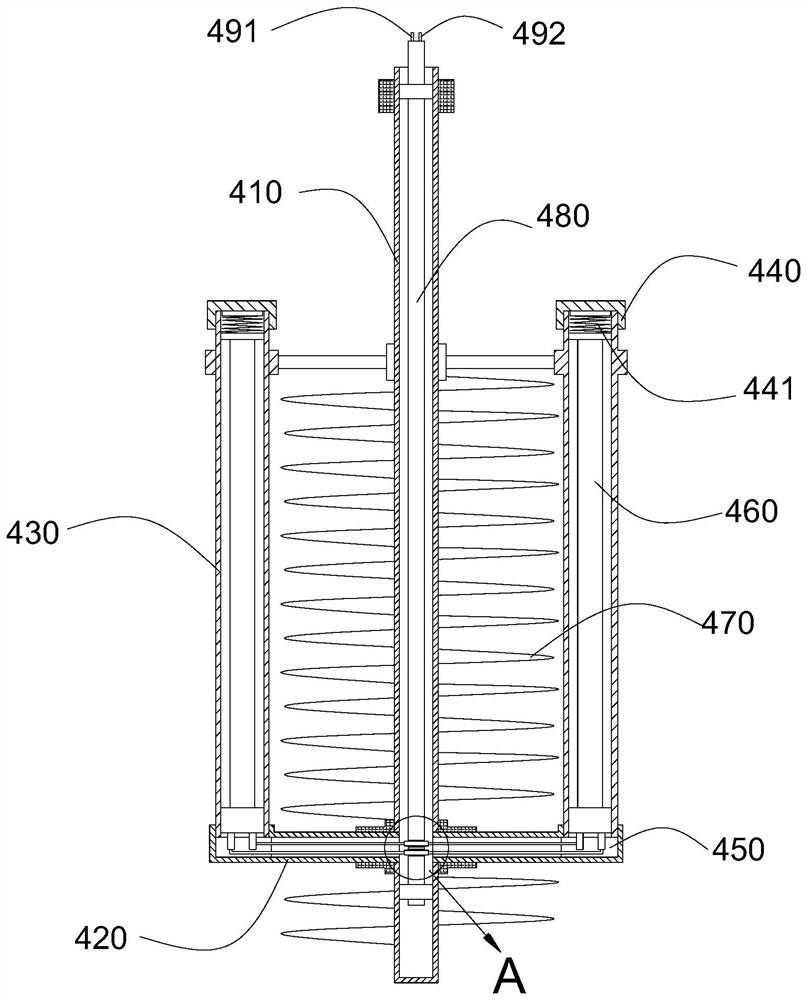

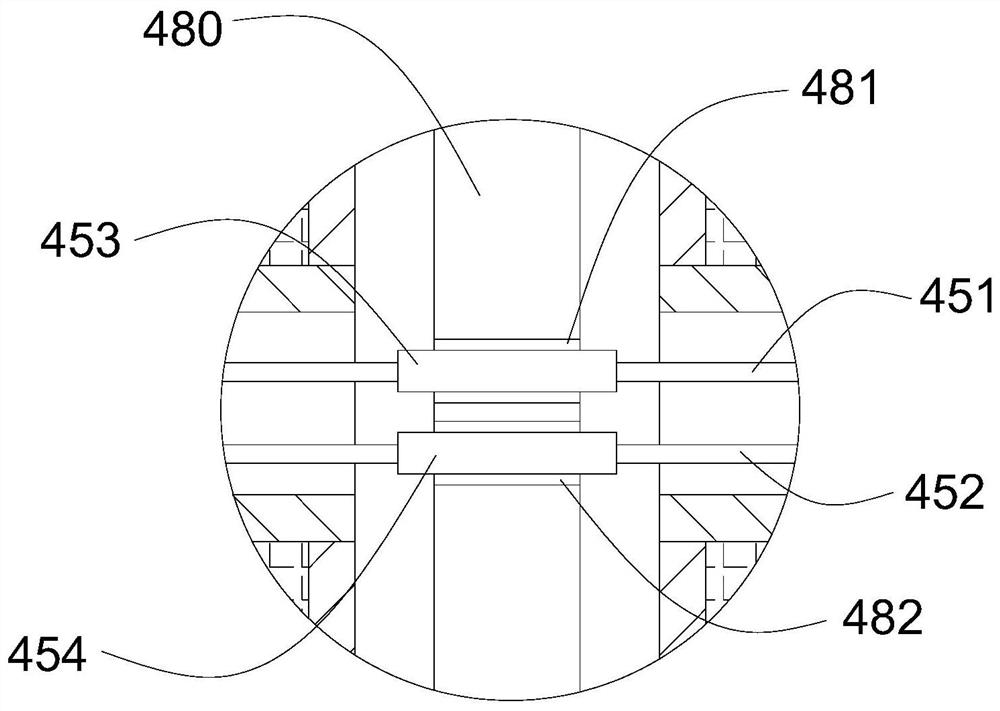

[0019] like Figure 1 to Figure 3 As shown, in the specific embodiment of the present invention, there is disclosed a stirring device for the production of barreled water barrels, which includes a barrel body 100 with an open top, a barrel cover 110 on the top of the barrel body 100, and a barrel cover 110 A hopper 120 is provided, and the bottom of the barrel body 100 protrudes downward to form a lower trough 130, which passes through the center of the bottom of the barrel body 100, and the lower end of the lower chute 130 is inclined and opened to form a Outlet, the outer side of the outlet is provided with a blocking structure 200, the blocking structure 200 is used to open or close the outlet; the first spiral stirring shaft 310 is installed in the lower trough 130 , the first spiral stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com