Assembling method of counter-force composite sports bicycle

An assembly method and sports car technology, which can be applied in transportation and packaging, vehicle parts, rider driving, etc., can solve the problems of inability to match the pushing and pulling torque of both hands and the pedaling torque of both legs, wear and tear, low work efficiency, and the riding process. Uncomfortable and other problems, to achieve the effect of beautiful riding posture, long service life and improved turning safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

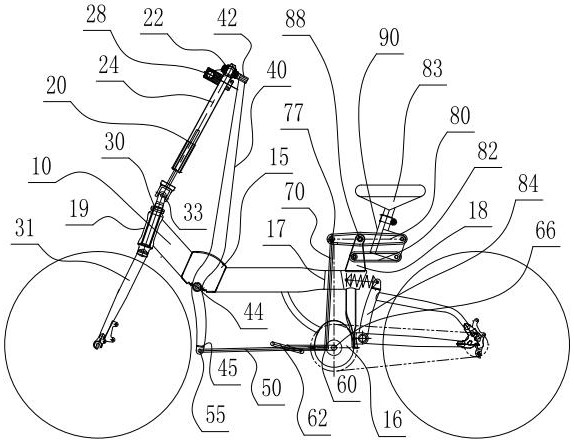

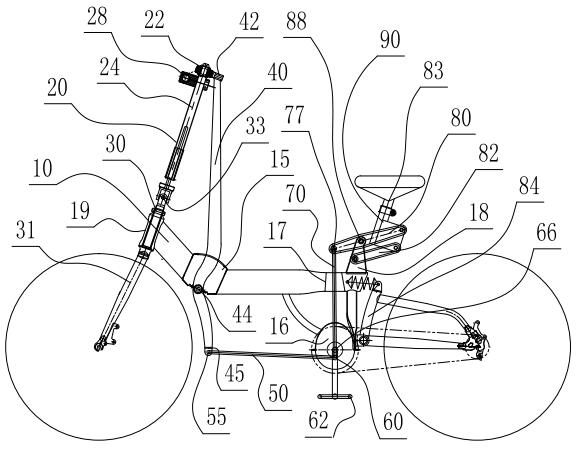

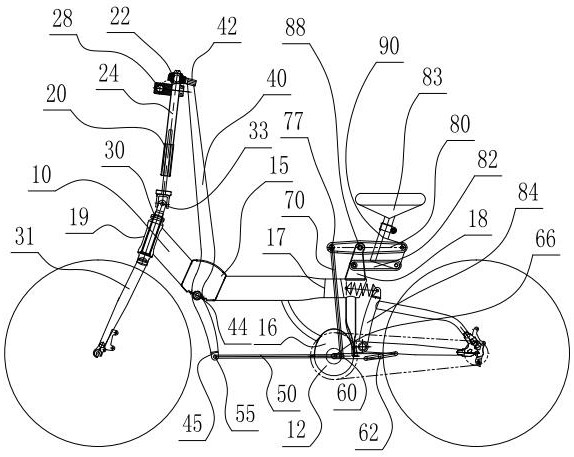

[0078] Figure 9 The front fork assembly 31 is omitted at least a conventional front wheel and front wheel brakes.

[0079] Figure 18 The rear fork assembly 84 is omitted at least as well as conventional ratchet sprocket wheel and rear wheel brakes with.

[0080] A reaction force motor complex car assembly comprising a frame assembly 10, a telescopic steering assembly 20, the front fork assembly 31 and a rear wheel fork assembly 84, carriage assembly 10 is rotatably fixed to the front end of the front fork assembly 31, carriage assembly 10 a rear end fixedly connected to a rear wheel fork assembly 84, as an improvement:

[0081] The upper end of the front fork assembly 31 is provided with an outer threaded through tube 39, through hole 39 threaded through the outer tube is removably fixed vertical core assembly 30, the main beam of the frame assembly 10 is provided with a reaction tube frame 15 , the reaction tube 15 may pivot block fixed to the reaction force of the oscillating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com