Multifunctional quartz glass continuous melting furnace

A quartz glass, continuous melting furnace technology, applied in glass furnace equipment, glass molding, glass manufacturing equipment and other directions, can solve the problems of slow cooling and forming speed, insufficient reaction, etc., to improve production efficiency, high practical value, speed up cooling The effect of forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

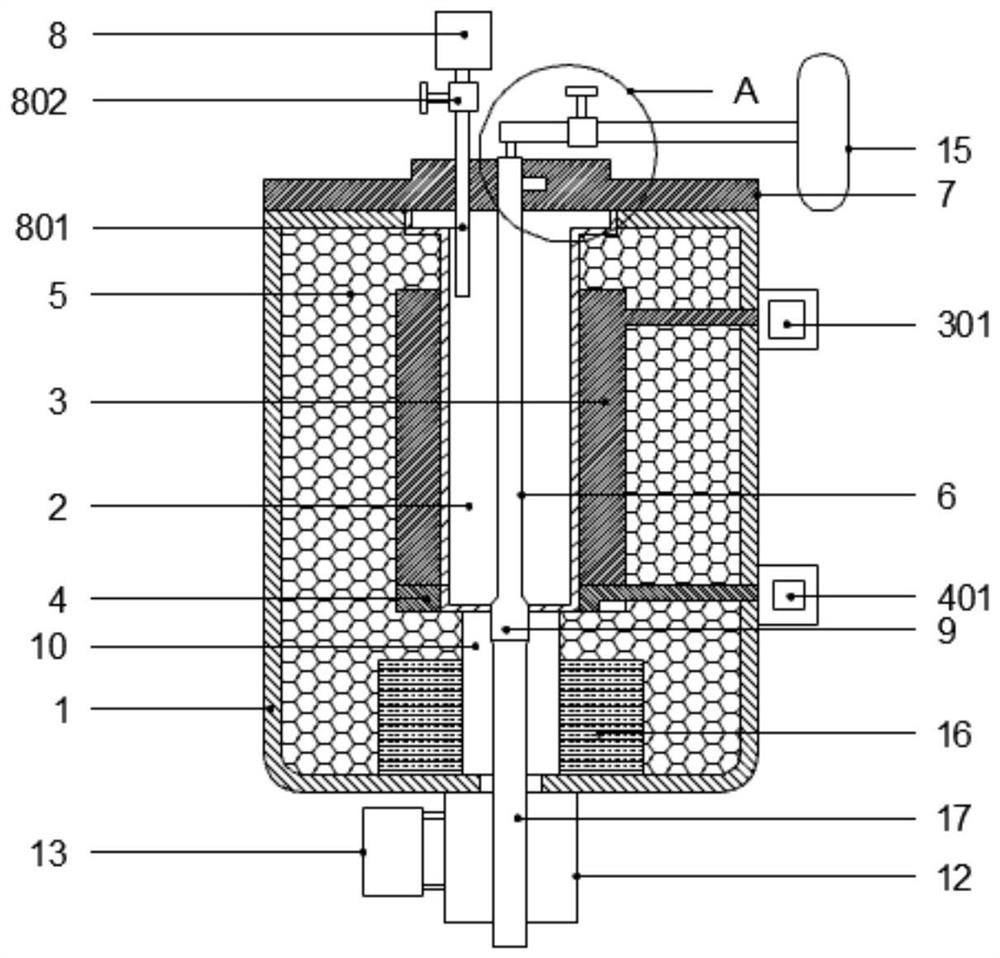

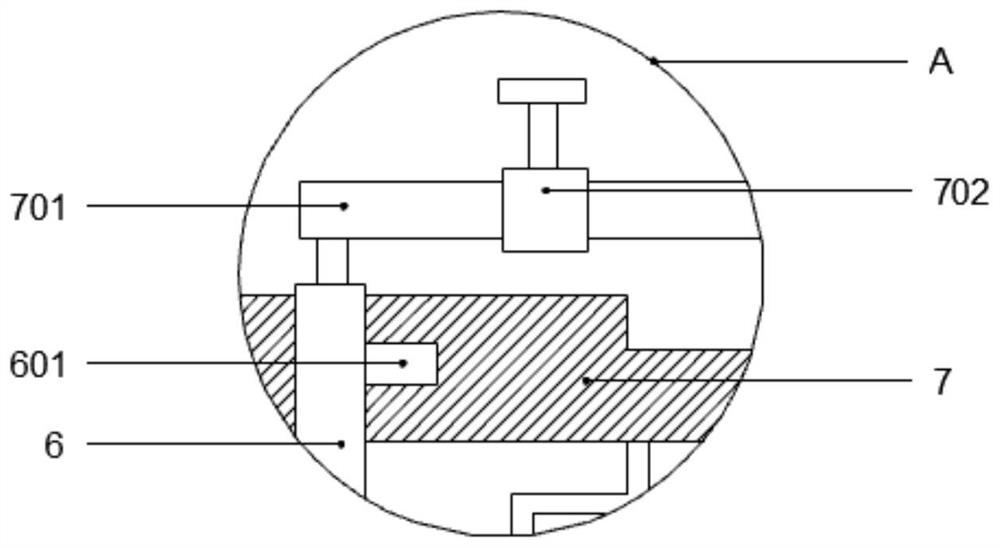

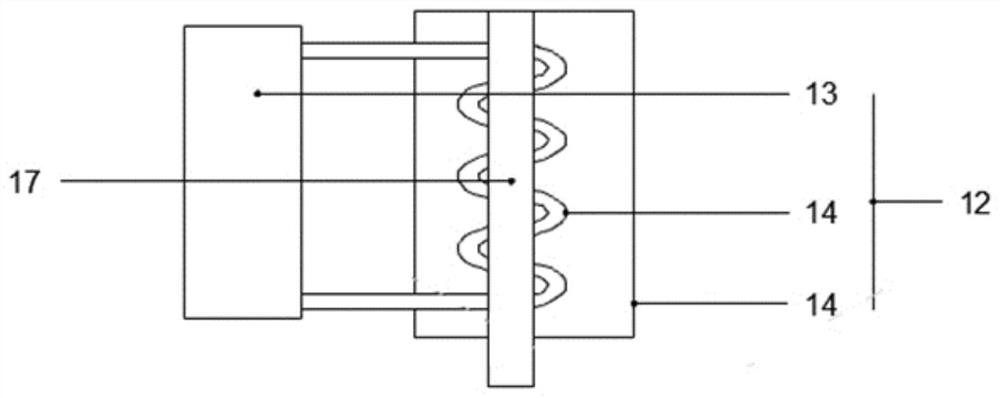

[0019] Example: such as Figure 1-3 As shown, a multifunctional quartz glass continuous melting furnace of the present invention includes a furnace body 1 and a crucible 2, a crucible 2 is fixedly installed in the furnace body 1, a first heating ring 3 and a second heating ring 4 are fixedly installed outside the crucible 2, The outer side of the first heating ring 3 and the second heating ring 4 is provided with an insulating layer 5, and the inside of the crucible 2 is provided with a core rod 6, a pressure sensor 601 is fixedly connected to one side of the core rod 6, and a furnace cover 7 is fixedly connected to the top of the core rod 6 And the air pipe 701, the top of the furnace cover 7 is connected with the feeder 8, the bottom end of the core rod 6 is fixedly provided with a molding die 9, the bottom end of the molding die 9 is provided with a molding outlet 10, and the bottom end of the molding outlet 10 is fixedly installed with a cooling device 11 , the cooling dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap