Novel plastic extruding machine with high product forming rate for manufacturing PVC (Polyvinyl Chloride) pipeline and method

A forming rate and extrusion machine technology, applied in the field of new extruders, can solve the problems of easy deformation of pipelines, affecting the quality of finished products, and lack of uniform mixing, so as to achieve reasonable structure, reduce friction, and prevent raw materials from clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

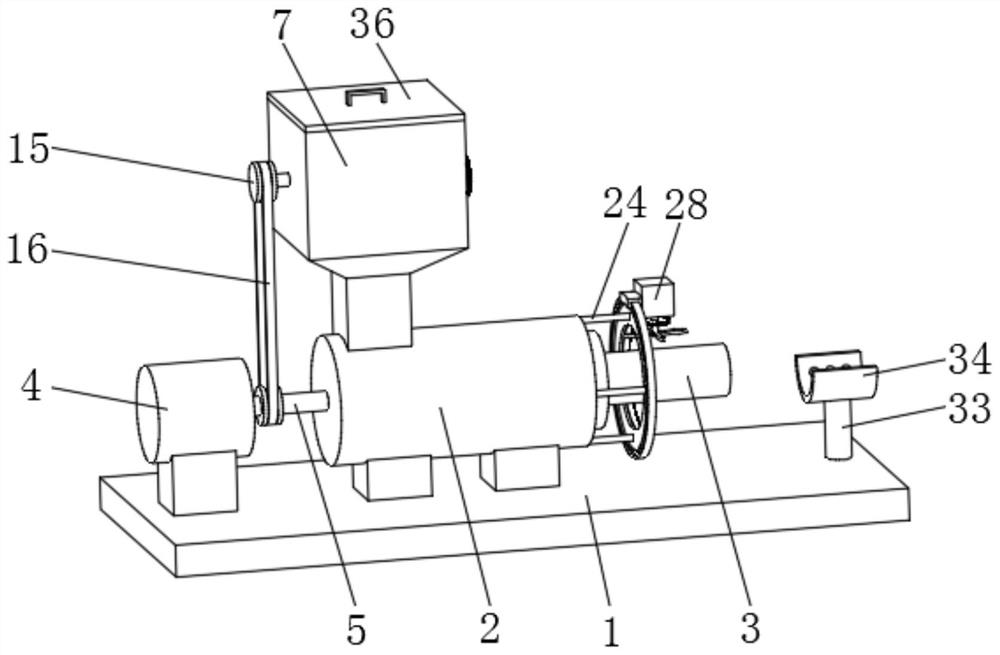

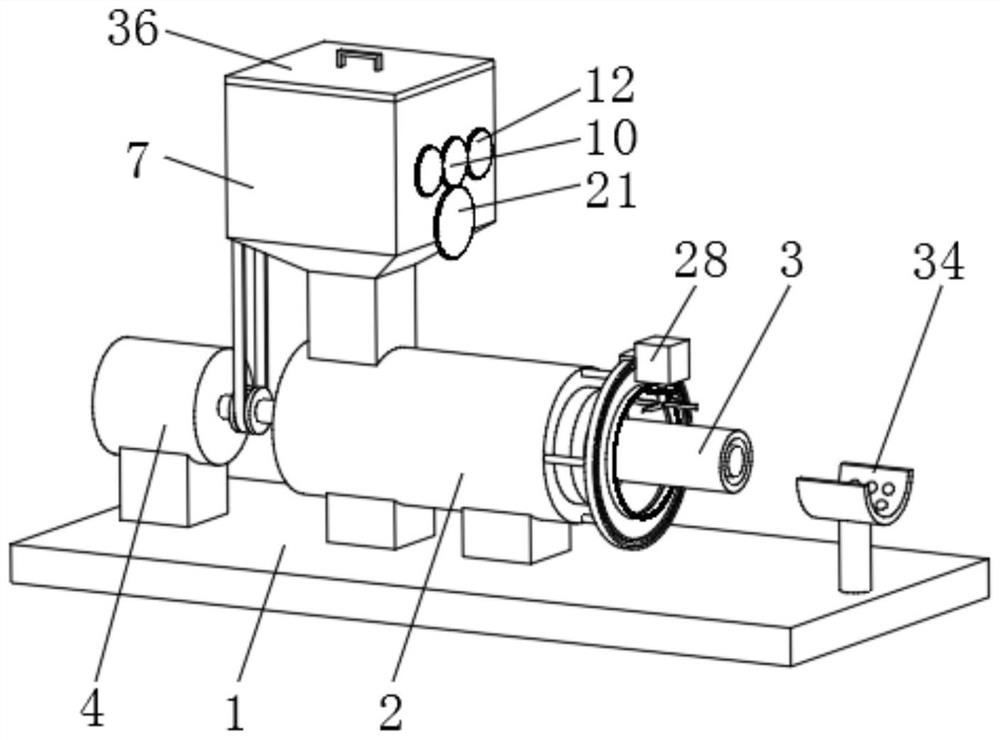

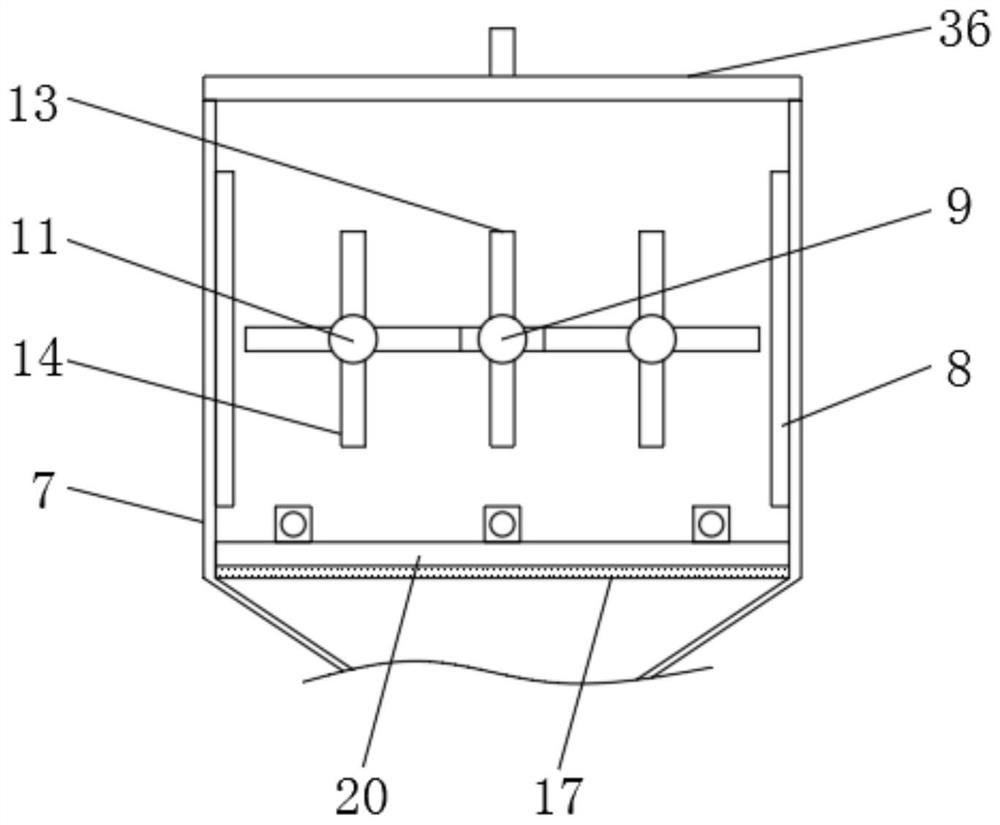

[0042] Example: Reference Figure 1-8 A new extruder with high product forming rate for PVC pipe manufacturing is shown, including a base 1, which can be any base structure in the prior art, such as a metal bottom plate.

[0043] The top side of the base 1 is fixedly installed with an extruder barrel 2 through a support platform, and the extruder barrel 2 can be any metal cylinder in the prior art, which is fixed by screwing the support platform with the top side of the base 1 .

[0044] One side of the extruder barrel 2 is fixedly installed with an extrusion pipe die 3, the extrusion pipe die 3 can be any pipe die structure in the prior art, and it is screwed to one side of the extruder barrel 2 for fixing .

[0045] The top side of the base 1 is fixedly installed with a drive motor 4 through the base, and the drive motor 4 can be any motor structure in the prior art, for example, the model is: 5IK120RGN, which is screwed through the base and the top side of the base 1. fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com