Production process of plastic glue

A production process and glue technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of complex production process, non-conventional production equipment, complex basic reaction principle, etc., to facilitate production The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present invention provides such as Figure 1-4 A kind of production technology of plastic glue, comprises the steps:

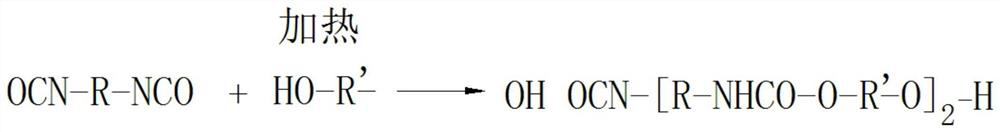

[0021] S1: Production and preparation of plastic A-type glue, standby, the raw materials of the plastic A-type glue include polyether polyol, paraffin and MDI;

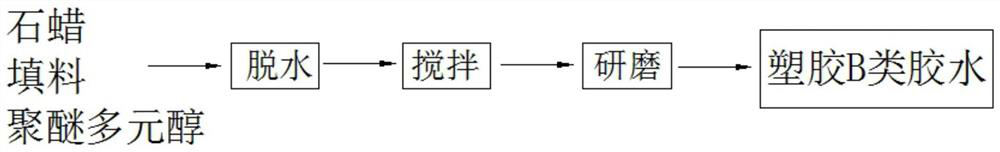

[0022] S2: Production and preparation of plastic B-type glue, standby, the raw materials of the plastic B-type glue include polyether polyol, paraffin and filler;

[0023] S3: Pellet Production:

[0024] After mixing raw stone powder and rubber granules, the rubber is mixed by an internal mixer, and the semi-finished rubber is extruded by an extruder, and then enters a steam vat for vulcanization to heat up the rubber and cross-link the rubber molecules. Its structure changes from a linear structure to a net-like body structure, and products with certain physical and mechanical properties are obtained, and then enter the crusher to be crushed into finished particles.

[0025] Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com