A method of using gypsum slag to strengthen recovery of valuable metals in copper smelting slag

A valuable metal and smelting slag technology, which is applied in chemical engineering, industrial solid waste resource utilization, and metallurgical engineering, can solve the problems of low metal comprehensive recovery rate, long preparation process, and increased slag viscosity, and achieve valuable metal The recovery rate is high, the process is simple and easy to realize, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Gypsum slag utilizing the present invention, enhanced recovery method of copper smelting slag with a divalent metal, comprising the steps of:

[0064] (1) A gypsum slag with a reducing agent B were mixed granulated mass ratio of 5, to control particle size of about 1mm, pellets drying stand.

[0065] (2) N 2 Atmosphere to a temperature of melting the slag 20g A 1250 ℃ was added 2g pellets, controlled cooling rate after 4 ℃ / min slow cooling to room temperature, i.e., slag-obtained.

[0066] Since the present embodiment is a laboratory, and A smelting slag is cooled the slag taken from the factory, it is necessary to 20g A smelting slag in N 2 Melting atmosphere at 1250 deg.] C; in the actual process, copper slag smelting process industrially produced slag itself is the melting temperature, the temperature is generally 1180 ~ 1320 ℃, so that no further heat can be directly processed, and is usually 20 ~ 50t of dross, slag inside the natural oxygen-free environment, using th...

Embodiment 2

[0072] Gypsum slag utilizing the present invention, enhanced recovery method of copper smelting slag with a divalent metal, comprising the steps of:

[0073] (1) gypsum slag with a reducing agent A B mass ratio of 3:1 kneading tableting, tableting pressure of 2Mpa.

[0074] (2) Take 20g B in slag smelting N 2 Atmosphere, was heated to 1200 deg.] C, 3g of plaster sheeting, slowly cooled to room temperature, controlling the cooling rate of 10 ℃ / min, to give the slow cooling slag.

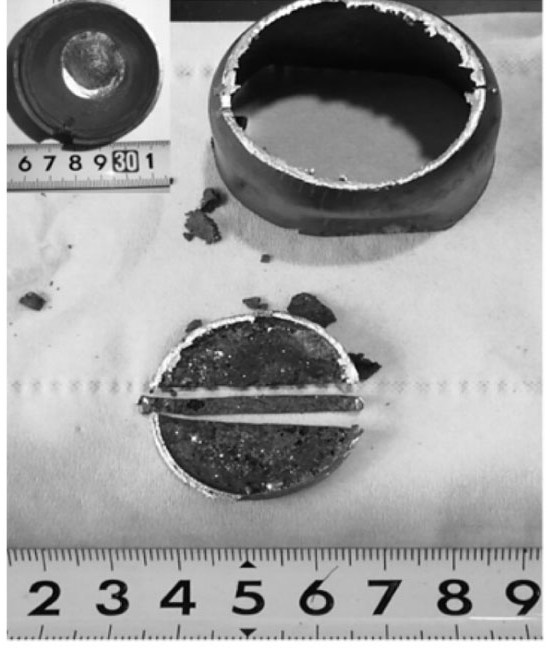

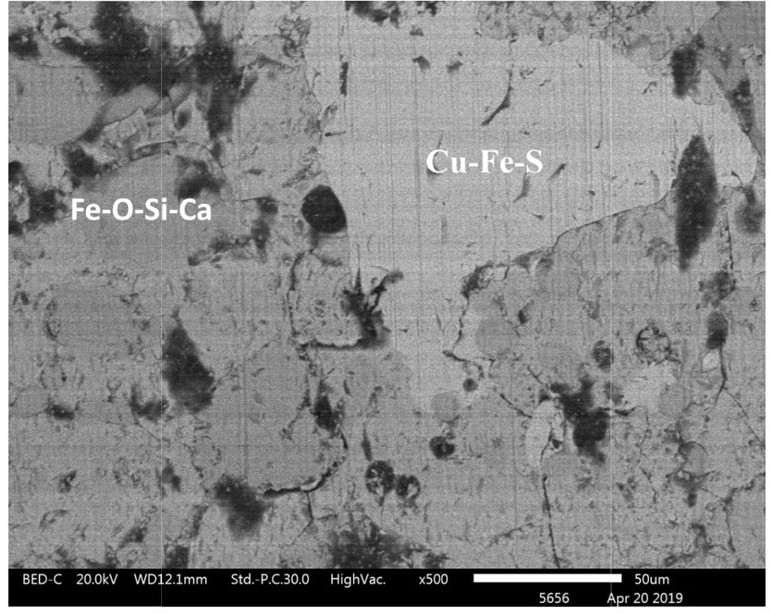

[0075] The resulting sample Figure 4 Shown completely melted slag and iron is deposited at the bottom of the crucible, loose surface structure of the sample produced by the reaction CO 2 And other gases escape formed. Original sample and slowly cooled slag directly detected by XRD Example 2 resulting slag-embodiment, the results obtained Figure 5 , The metallographic sample preparation the samples were analyzed by SEM, the results obtained Image 6 Indicated.

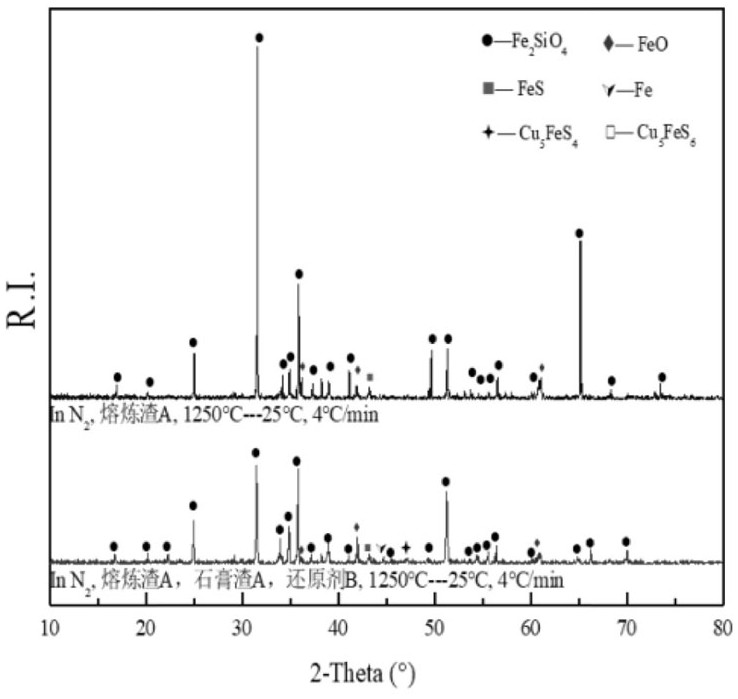

[0076] Figure 5 The XRD detection results sh...

Embodiment 3

[0079] A method of using gypsum slag to reagent in recovery of copper mesencing slums in the use of plasma slag, including the following steps:

[0080] (1) Powering the gypsum slag B and the reducing agent B in mass ratio of 1: 1, the ball is 2 mm.

[0081] (2) Take 20G Solution 14 in N 2 The atmosphere was warmed to 1250 ° C, add 4 g of the ball, slowly cooled to room temperature, and the cooling rate was 2 ° C / min, that is, the cold slag was obtained.

[0082] The sample Figure 7 As shown, the slag is completely melted and deposited at the bottom of the cast iron, and the sample surface loose structure is generated by the reaction. 2 Waiting for gas escape. The original slag direct cache sample and the cache residue obtained from Example 3 were subjected to XRD detection. Figure 8 As shown, the sample is metapped by the sample, and the results are analyzed by SEM. Figure 9 Indicated.

[0083] Figure 8 The XRD detection result shows that CASO is not detected by a slow-cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com