Wall holing waste liquid collection device and construction method

A waste liquid collection and wall technology, which is applied in construction, building structure, construction material processing and other directions, can solve problems such as pollution, and achieve the effect of solving pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

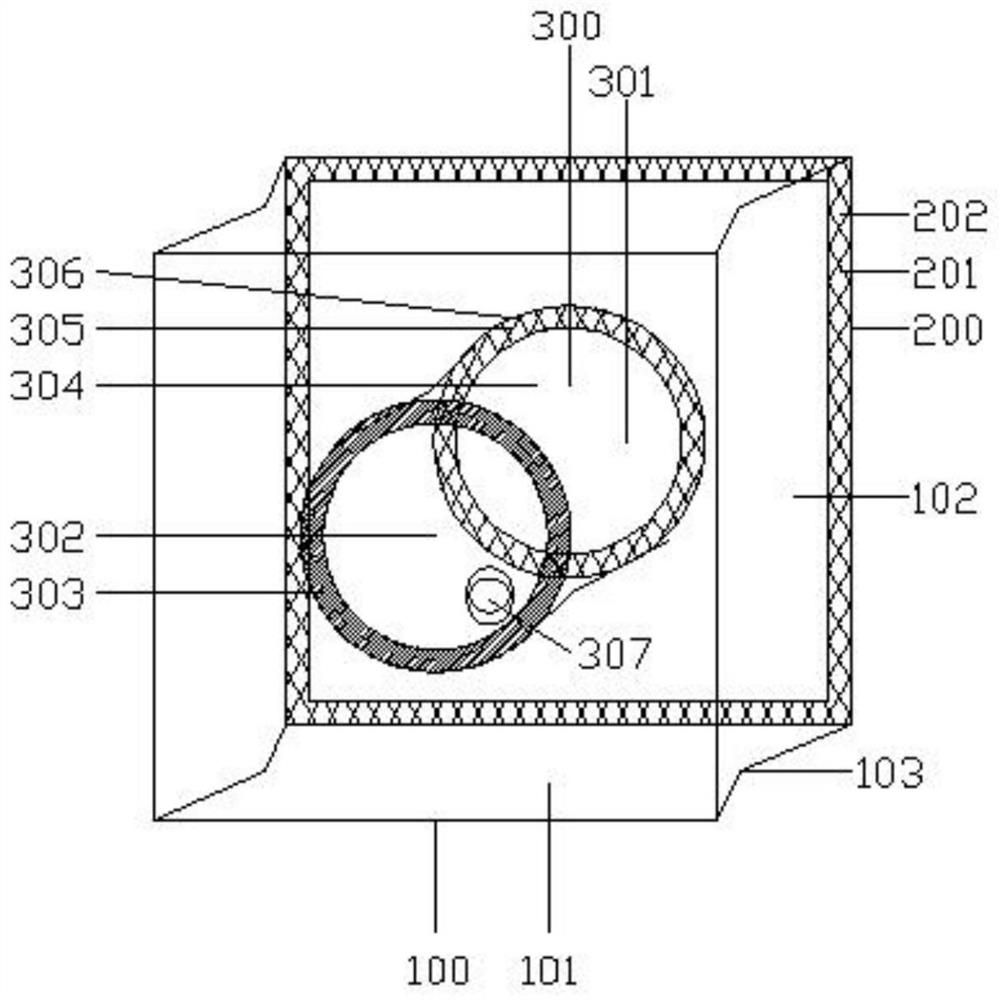

[0028] A waste liquid collection device for opening holes in the wall, including a container 100, a connector 200 and a diverter 300, the connector 200 is arranged on the back of the container 100, and is used to connect with the wall to be opened, and the diverter 300 runs through it horizontally The center of the container 100 is used as a channel for the drilling stroke of the rhinestone drill bit;

[0029] The container 100 includes a front panel 101, a back panel 102 and a side panel 103. The front panel 101 and the back panel 102 are parallel to each other and have the same size. The front panel 101 and the back panel 102 pass through a total of four sides: up, down, left and right. The panels 103 are connected, the front panel 101 and the back panel 102 are provided with openings, the two openings are equal in size, the front panel 101, the back panel 102 and the side panels 103 are combined into a closed box-shaped structure for collecting waste liquid from the opening;...

Embodiment 2

[0039] A construction method for a waste liquid collection device with holes in the wall, comprising the following steps:

[0040] Step 1: Stake out the position of the hole. Measure the position and size of the hole to be opened on the wall;

[0041]Step 2: Device installation, first align the center of the rear port 304 of the device with the center of the hole to be opened, tear off the film 2 306 and fix the rear port 304, then tear off the film 1 202, and place the rear port The back panel 102 of 304 circles is pasted on the wall, and finally the whole device is fixed on the wall;

[0042] Step 3: The rhinestone is installed in place, and the drill bit is passed through the folded front port 302, cavity 301, and rear port 304 in turn, and then aligned with the center of the planned hole on the wall;

[0043] Step 4: Device adjustment, stretching the side panel 103 and cavity 301 of the device outward along the axis of the rhinestone drill bit to open;

[0044] Step 5: D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com