Rapid brick watering device for building

A sprinkling device and technology for construction, applied in the direction of construction, building structure, construction materials, etc., can solve the problems of low work efficiency, poor work quality, uneven watering, etc., to improve work quality, spray water evenly, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

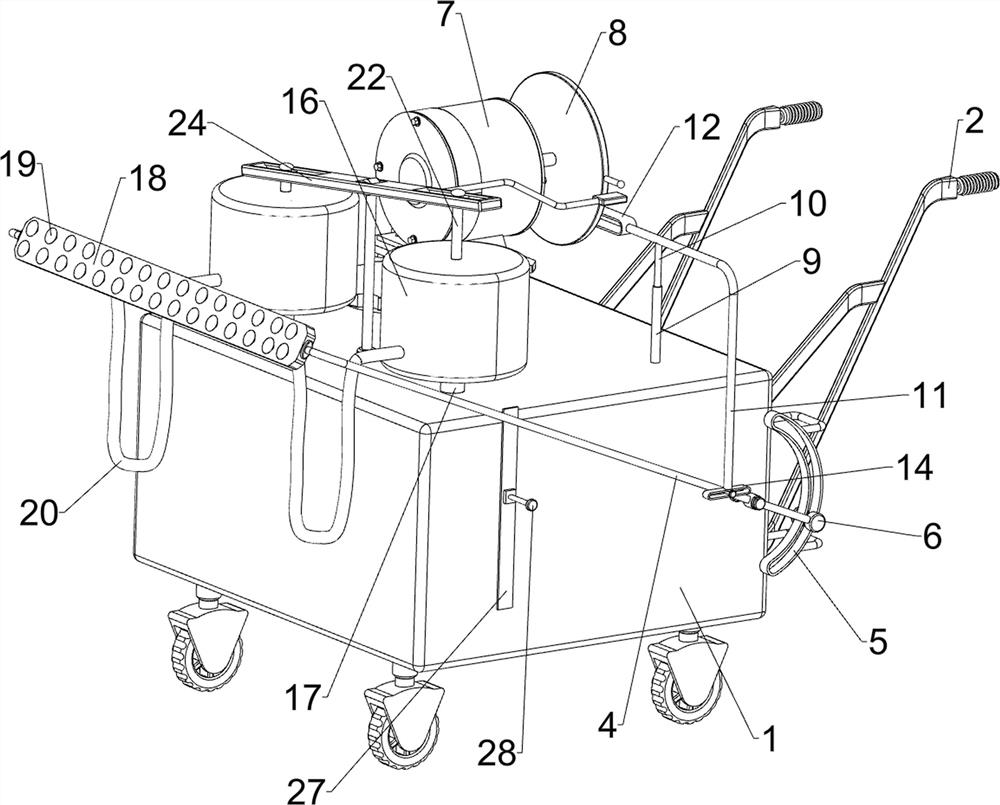

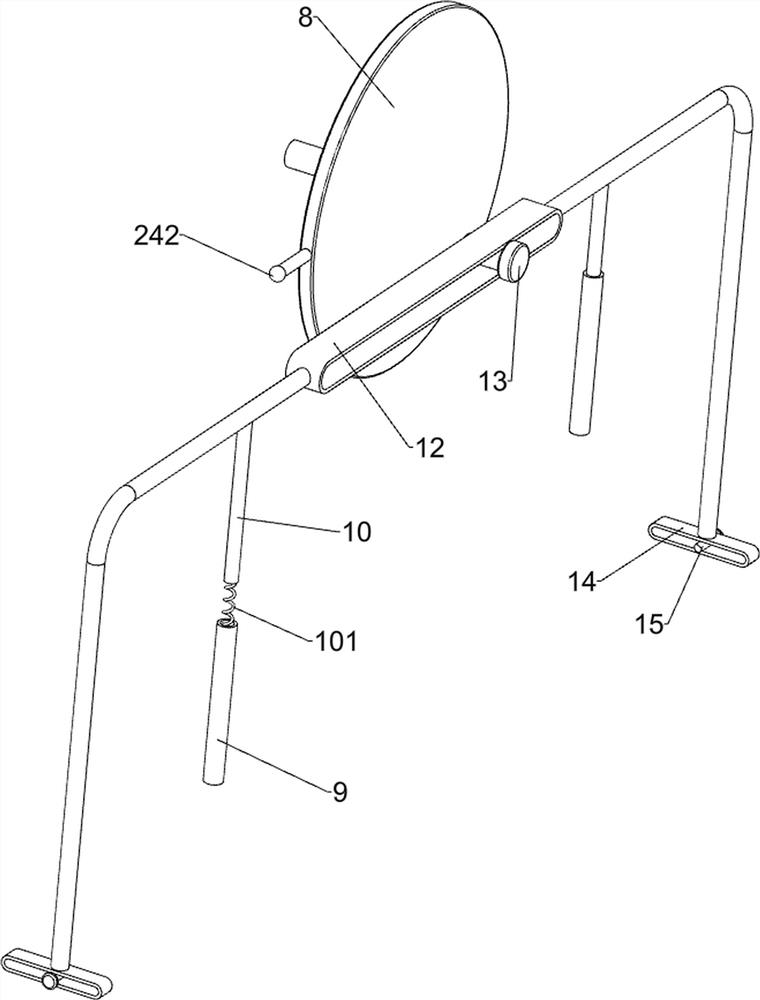

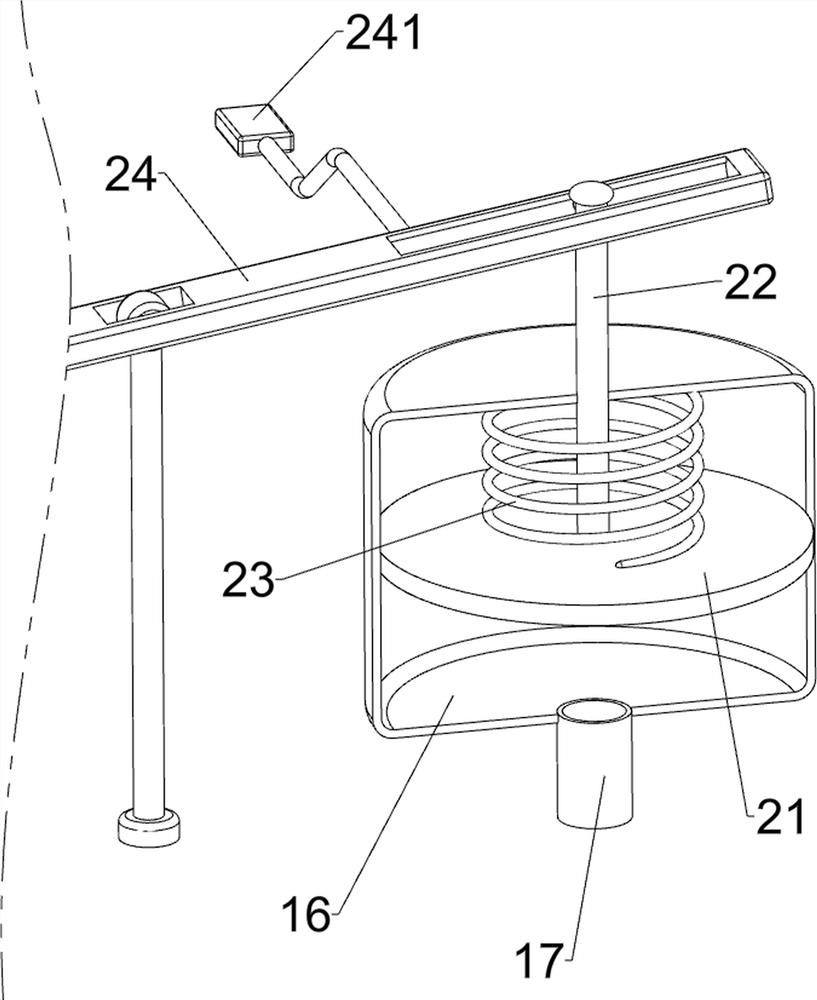

[0019] A quick sprinkling device for building bricks, such as Figure 1-4 As shown, it includes a water tank 1, a push handle 2, a water outlet pipe 3, a swing assembly, a power assembly and a water spray assembly. The water pipe 3 and the water tank 1 are provided with a swing assembly that swings by rotation, the water tank 1 is provided with a power assembly that provides power by rotation, and the water tank 1 is provided with a water spray assembly that sprays water by sliding.

[0020] When using this equipment to sprinkle water on the bricks, the staff pours enough water into the water tank 1, and then pushes the equipment forward through the push handle 2, and then the staff drives the water spraying assembly to spray water on the bricks through the power assembly, and then When spraying water, the swing assembly drives the water spray assembly to swing up and down to spray water. After the water spray is completed, the staff closes the power assembly, and then opens t...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 and Figure 4As shown, it also includes a fourth slider 26, a baffle plate 27, a cross bar 28, a connecting rod 29, a brush plate 30, a guide rod 31, a sliding sleeve 32 and a third spring 33. Chute 25, all sliding type is provided with the 4th slide block 26 in the straight chute 25, is all welded with baffle plate 27 on the 4th slide block 26, is all welded with cross bar 28 on the outside of the 4th slide block 26, cross bar 28 All cooperate with pendulum 4, the inside of the fourth slide block 26 is all rotatable to be provided with connecting rod 29, and the bottom of connecting rod 29 is all rotatable to be provided with brush board 30, and brush board 30 contacts with water tank 1 bottom, and water tank 1 inner lower part front and back A guide rod 31 is welded between the two sides, and the front and rear sides of the guide rod 31 are slidingly provided with a sliding sleeve 32, and the sliding sleeve 32 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com