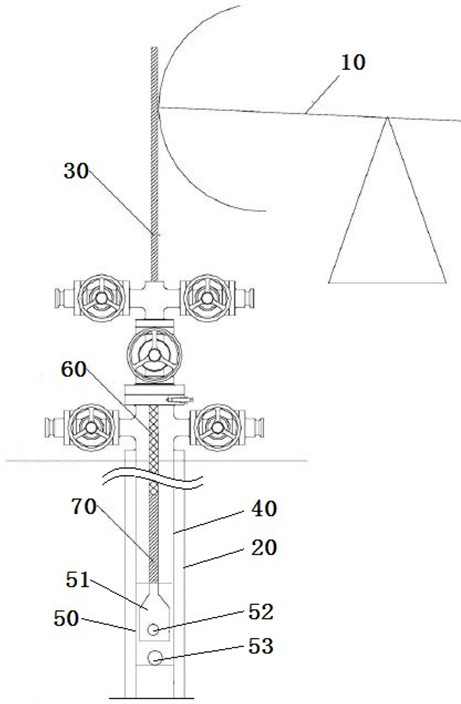

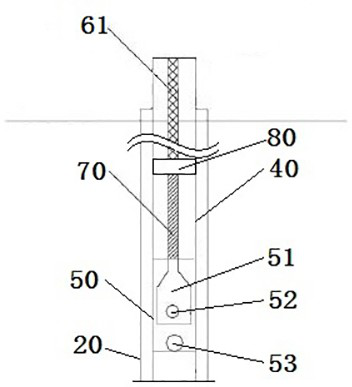

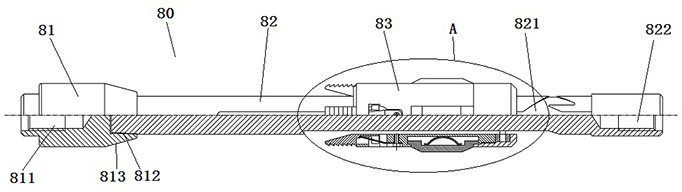

Method for adjusting depth of oil well pump

An adjustment method and oil well pump technology, which are applied to pumps, earthwork drilling, pumps with flexible working elements, etc., can solve the problems of long operation time, high cost, and low operation efficiency, so as to reduce workload and facilitate disassembly and assembly , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0062] Embodiment 2 of the method for adjusting the pump depth of the oil well pump in the present invention: In this embodiment, when lifting the oil well pump, starting from improving efficiency, the sending distance of the fixing device into the oil rod is approximately equal to the distance that the oil well pump needs to be lifted. In this case, the downstroke of the fixing device is short, which saves production resources and shortens the time for pump depth adjustment.

Embodiment 3

[0063] Embodiment 3 of the pump depth adjustment method of the oil well pump in the present invention: In this embodiment, when the oil well pump is lowered, considering the construction safety, the fixing device can be fixed with the inside of the oil pipe located in the middle. When connected, the fixing device is located in the oil pipe and will not be exposed, so that the fixing device and its connected lower sucker rod and plunger will not be damaged.

Embodiment 4

[0064]Embodiment 4 of the method for adjusting the pump depth of the oil well pump in the present invention: In this embodiment, while removing the upper part of the sucker rod, the technician also grasps the remaining sucker rod and plunger through tools, which is not limited Just fix remaining sucker rod and plunger before pulling down described upper part sucker rod. Or before removing the upper part of the sucker rod, use a lock to fix the remaining sucker rod and plunger, not limited to the way of hoisting to fix the remaining sucker rod and plunger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com