Strength detection device for organic glass processing

A strength detection, plexiglass technology, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of inconvenient fixing of glass of different sizes, affecting detection efficiency, inconvenient use, etc., to improve the fixed range, ensure accuracy, The effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

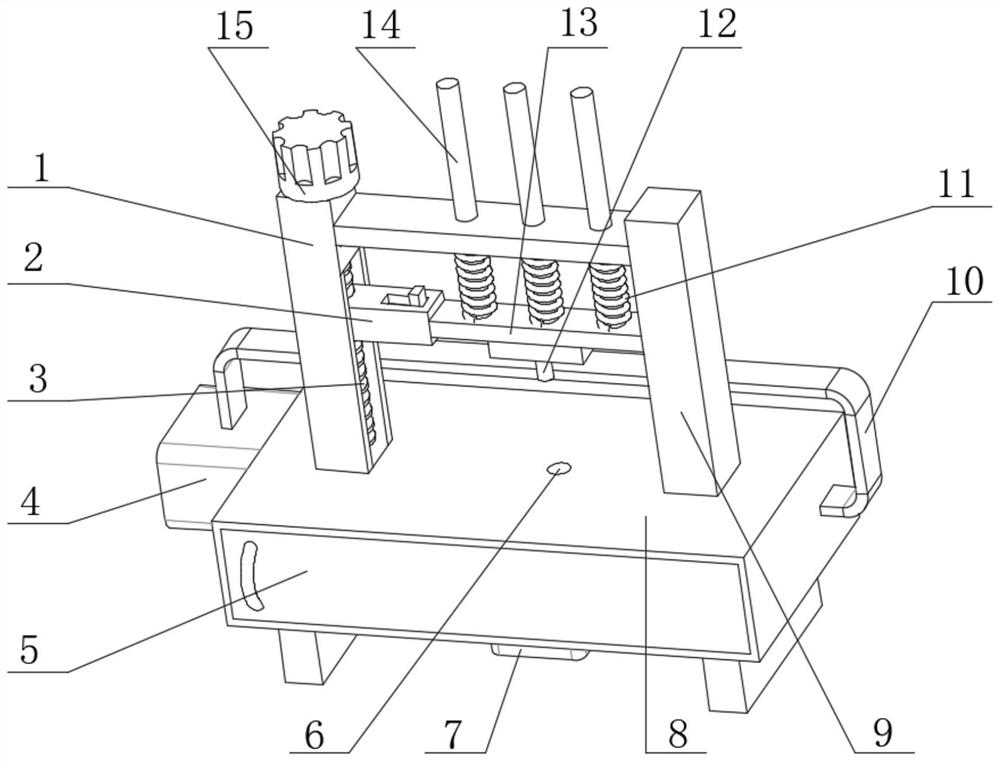

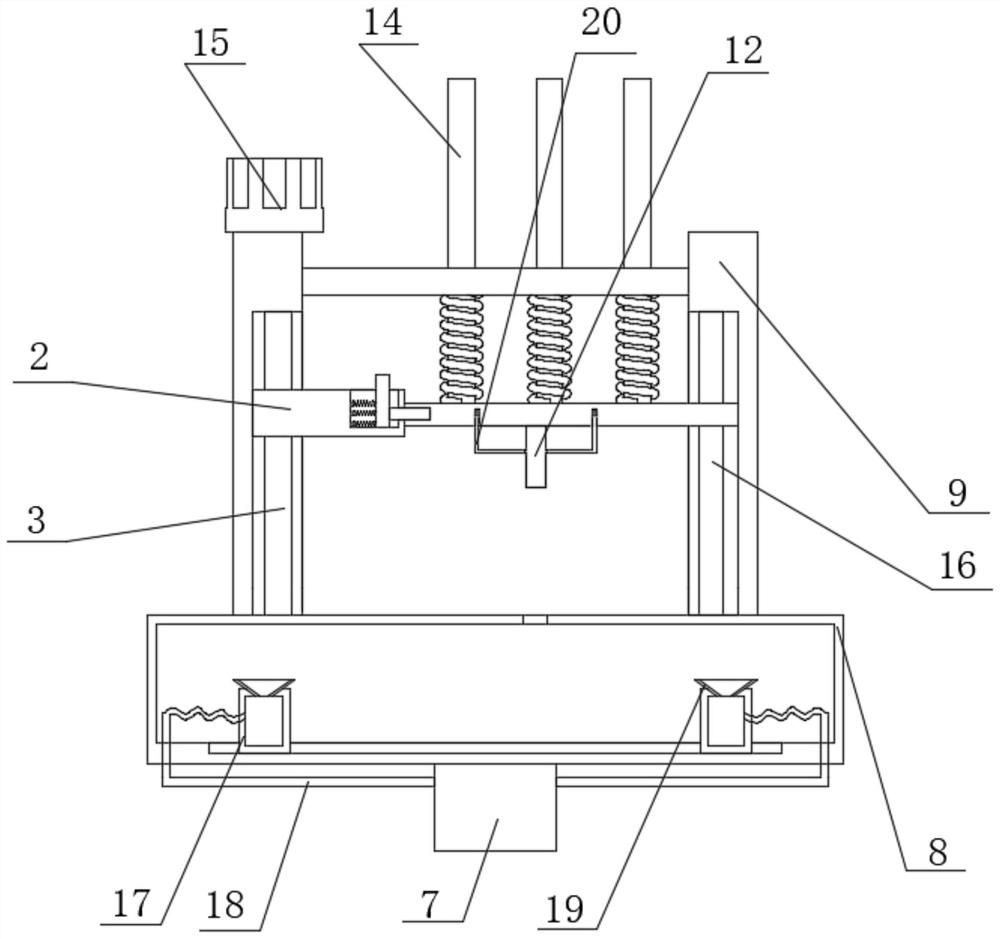

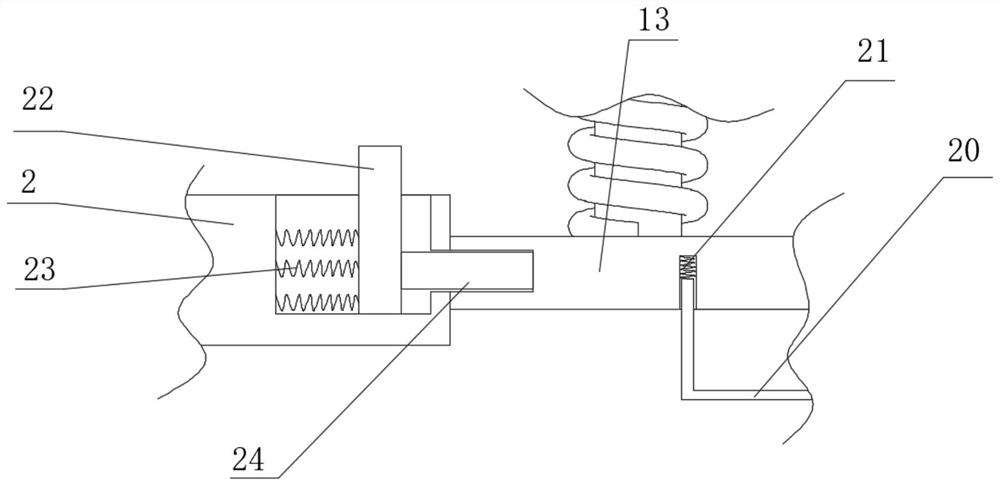

[0029] refer to Figure 1-4 , a strength detection device for plexiglass processing, comprising a fixed housing 8, the inner wall of the bottom of the fixed housing 8 is provided with a first limiting groove, and the inner wall of the first limiting groove is slidably connected with two intake housings 17, and The outer wall of the top of the gas housing 17 is plugged with suction cups 19 distributed equidistantly, and the first support column 1 is installed on one side of the top outer wall of the fixed housing 8, and the outer wall of the first support column 1 is provided with a first mounting groove. The top and bottom inner walls of the mounting groove are rotatably connected to the same screw 3, the outer wall of the screw 3 is rotatably connected to the sliding block 2, and the outer wall of the top of the fixed housing 8 is equipped with a second support column 9, and the outer wall on one side of the second support column 9 A second installation groove is provided, an...

Embodiment 2

[0034] refer to Figure 1-5 , a strength detection device for plexiglass processing, which also includes a fixed frame mounted on the inner wall of the top side of the fixed housing 8, and rotating fan blades 28 equidistantly distributed on the outer wall of one side of the fixed frame.

[0035] Working principle: Compared with Embodiment 1, through the fixed frame and the rotating fan blade 28 arranged on the fixed housing 8, the air from the other end of the circulating air pipe 10 will drive the circulating air pipe 10 to rotate, so that the hot or cold air can be fully dispersed Inside the fixed housing 8, the accuracy of the detection result is improved, making the device more perfect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com