A high-temperature in-situ pressure calibration diamond anvil press and pressure calibration method

A technology of diamond countertop and diamond anvil, which is applied in the field of physical quantity measurement, can solve problems such as pressure value calculation errors, affecting the accuracy of pressure values, and difficulty in obtaining experimental pressure values, so as to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] combined with Figure 1-12 The device structure and assembly of the present invention will be described.

[0039] A high-temperature in-situ pressure calibration diamond-anvil press of the present invention comprises three parts: a pressure transmission module, a pressure calibration module and a heating experiment module. in:

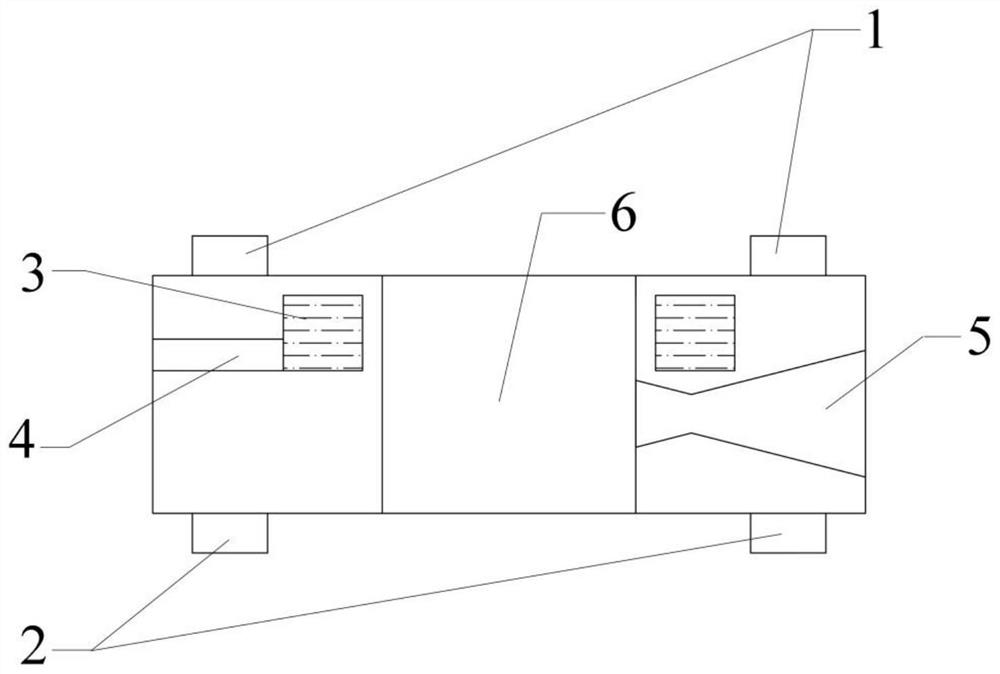

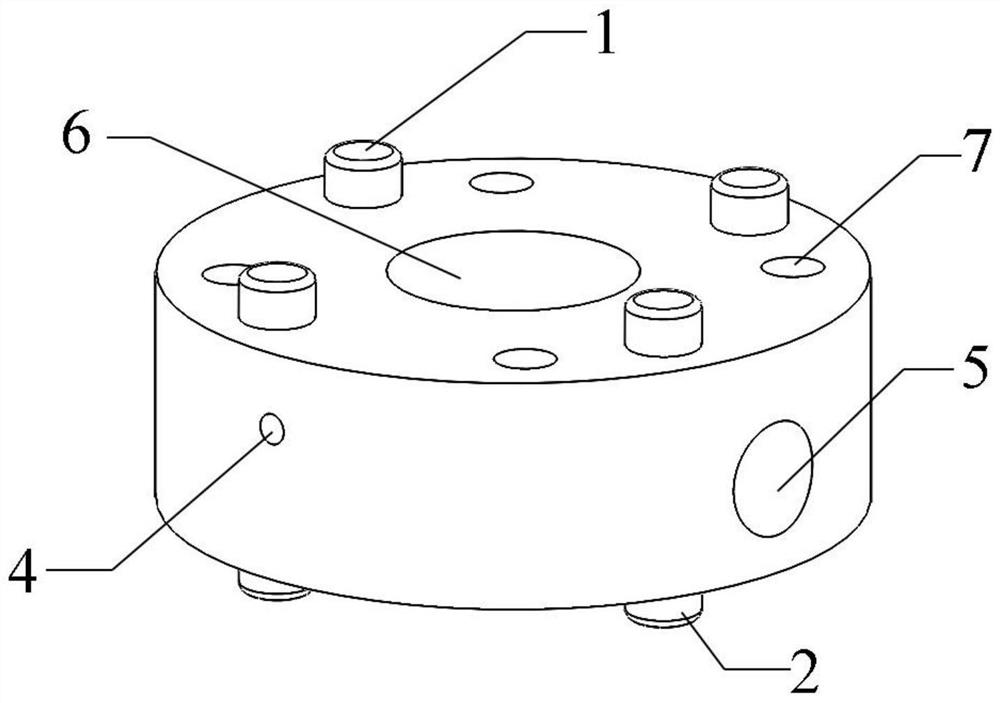

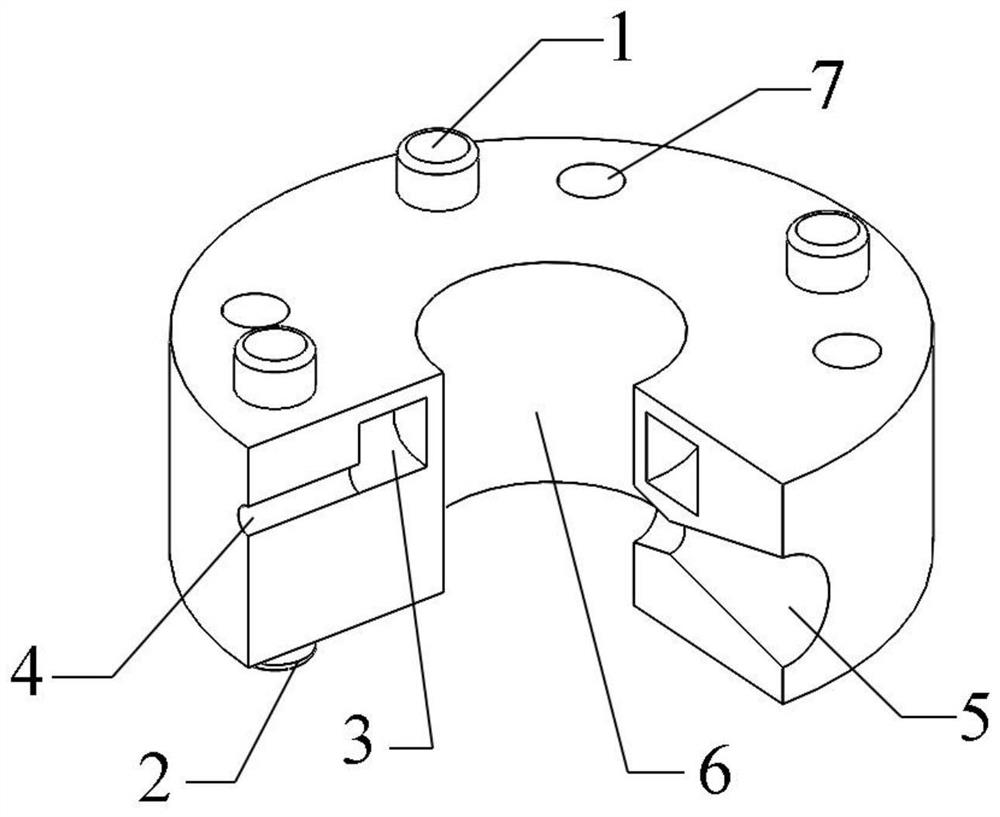

[0040] The structure of the pressure transmission module is shown in the attached Figure 1~3 , the upper and lower surfaces are respectively provided with an upper limit column 1 and a lower limit column 2. The axis of the pressure transmission module has a main light-transmitting hole 6 that runs through the upper and lower surfaces of the pressure transmission module. Auxiliary light-transmitting holes 5, inside the water-cooling chamber 3 and the external connection hole 4 of the water-cooling chamber, the external connection hole 4 of the water-cooling chamber are used for the conduction between the water-cooling chamber 3 and the outside...

Embodiment 2

[0046] Utilize the present invention to carry out the steps of diamond-to-anvil press pressure calibration:

[0047] First, by screwing into the adjustment screw hole 17 the pressure calibration trapezoidal pad adjustment screw 11, the pressure calibration spherical pad bed position adjustment screw 21, the heating module spherical pad bed position adjustment screw 28, the heating module trapezoidal The adjustment function of the pad adjustment screw 29 makes the heating module diamond anvil 37 and the pressure calibration diamond anvil 19 concentric;

[0048] Afterwards, the position of the axis between the pressure calibration diamond anvil 19 and the contact surface of the pressure calibration pressure pad 20, and the position of the axis of the contact surface between the heating module diamond anvil 37 and the heating module pressure pad 38, Place the rubies separately, and use the ruby fluorescence method to calibrate the initial fluorescence peak position of the ruby;...

Embodiment 3

[0054] The effectiveness of the high-temperature in-situ pressure calibration diamond-to-anvil press pressure calibration method of the present invention is proved by practical examples:

[0055] According to the maximum pressure value P required by the experiment is 10GPa, based on the pressure in the heating experiment module, pressurize 5 times from 0GPa at equal pressure intervals, and record the pressure value P of the heating experiment module for 5 times J1 =2.04GPa, P J2 =4.06GPa, P J3 =5.99GPa,P J4 =7.96GPa,P J5 =10.01GPa, at the same time record 5 pressure values P in the pressure calibration module B1 =2.70GPa, P B2 =5.22GPa,P B3 =7.91GPa,P B4 =10.63GPa,P B5 =13.28GPa; according to the coaxial axial total pressure is equal, fitting P J1 ,P J2 ,P J3 ,P J4 ,P J5 , P B1 ,P B2 ,P B3 ,P / 4 ,P B5 interrelationships, such as Figure 13 , get P J with P B The corresponding fitting relationship is 1.32P J =P B .

[0056] After any pressure is passed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com