Composite scanning chlorion sensitive micro-probe and preparing process thereof

A microprobe and chloride ion technology, applied in the field of probes, can solve the problems of short service life of liquid membrane electrodes, difficulty in making microelectrodes, slow response speed, etc., and achieve simple preparation process, improved spatial resolution, and tip size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

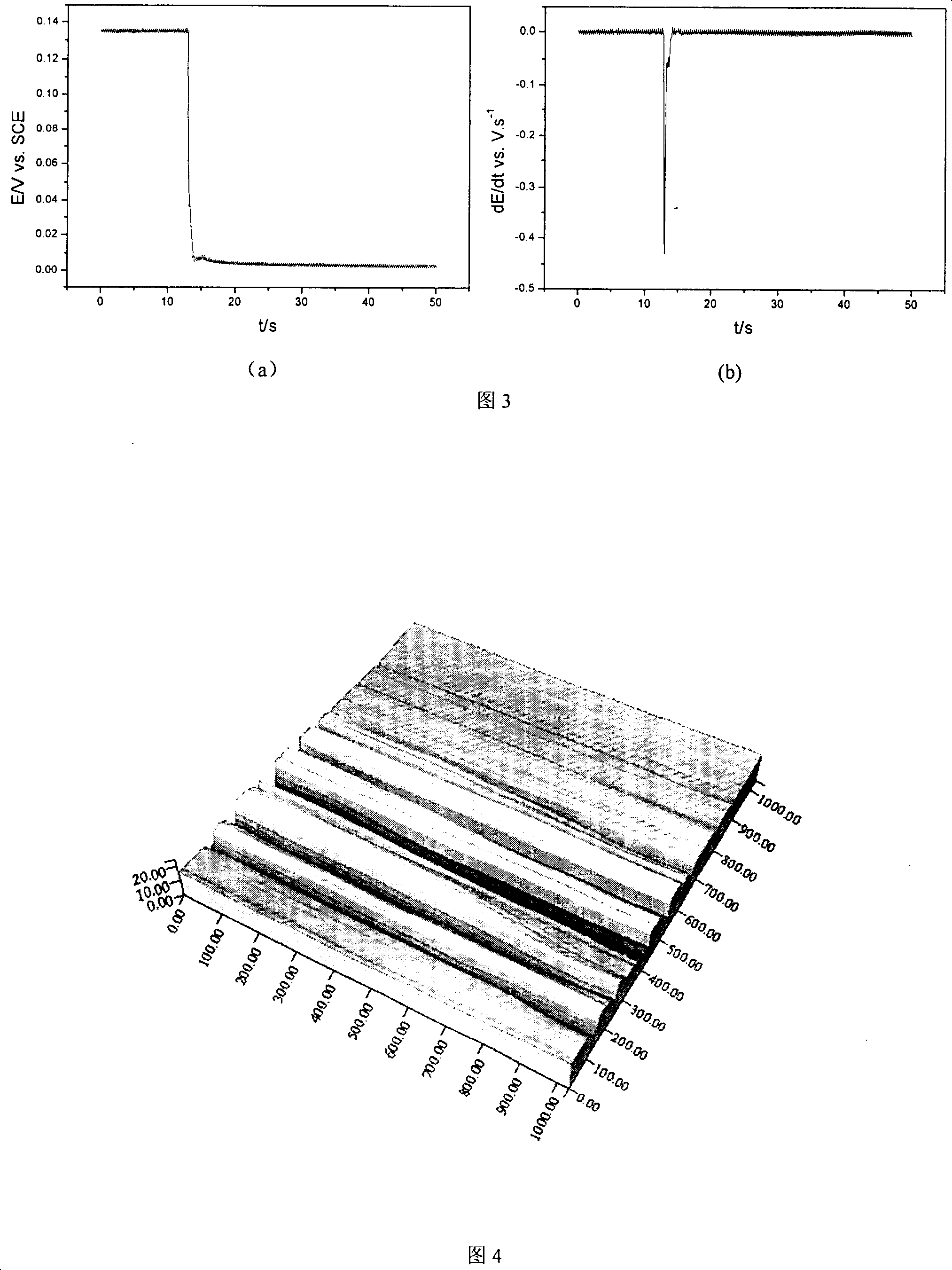

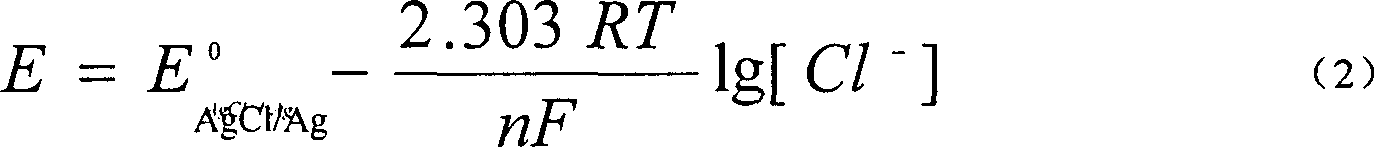

[0025] The drugs used are all analytically pure, and the preparation solution uses three times of deionized water. The measurement of Ag / AgCl electrode potential-concentration curve and potential-time curve is completed by the Autolab electrochemical workstation of Eco Chemi Company. The 18-8 stainless steel is polished with 400 to 1000 water abrasive paper in turn, polished with 1 μm alumina polishing powder to a mirror surface, ultrasonically cleaned with anhydrous ethanol and water three times, and dried. The micro-area scanning measurement of the chloride ion concentration on the metal surface was completed by the scanning electrochemistry / scanning tunneling microscope system developed by Xiamen University.

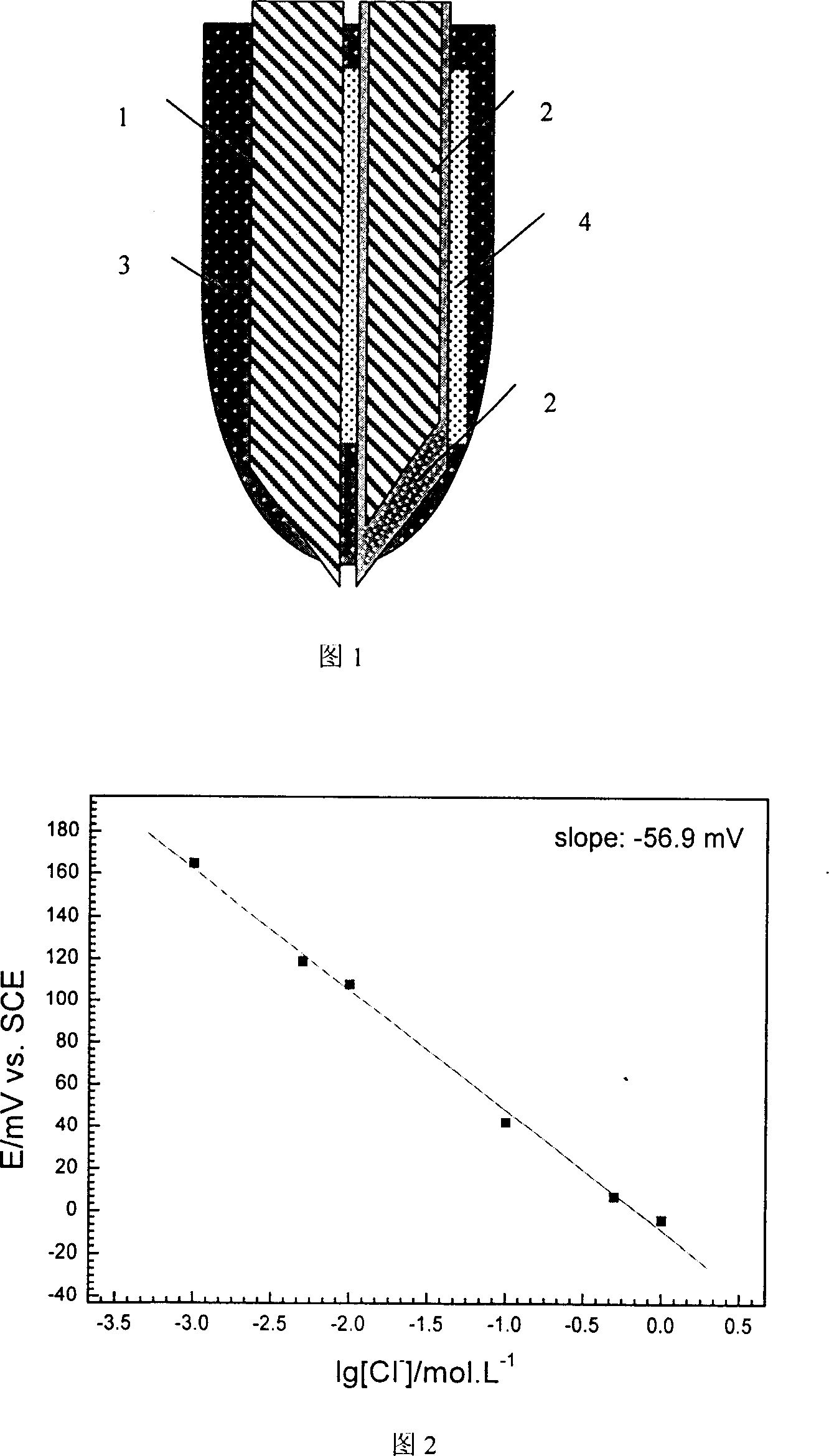

[0026] First, take a pure silver wire with a length of 20mm and a diameter of 0.2mm, mechanically cut out a tip of 50μm at one end with sharp scissors, and then perform a constant current anodizing treatment in a HCl solution with a concentration of 0.01mol / L for 3h, ...

Embodiment 2

[0031] Similar to Example 1, the difference is that when preparing the Ag / AgCl electrode, a pure silver wire with a length of 50 mm and a diameter of 0.3 mm was used to mechanically cut out a tip of 70 μm at one end with sharp scissors, and then in a concentration of 0.001mol / L Constant current anodizing treatment in HCl solution for 5h, the control current is 0.001mA / cm2. After the anodization is completed, a layer of tan and dense AgCl film is uniformly formed on the surface of the silver wire. After the Ag / AgCl electrode was rinsed with distilled water and dried, the surface was evenly coated with a layer of nail polish with a thickness of 1 μm. When preparing the reference probe, a 50 μm tip was processed at one end of a Pt-Ir alloy (Pt70%-Ir30%) wire with a length of 50 mm and a diameter of 0.3 mm.

Embodiment 3

[0033] Similar to Example 1, the difference is that when preparing the Ag / AgCl electrode, a pure silver wire with a length of 70 mm and a diameter of 0.1 mm was used to mechanically cut out a 20 μm tip at one end with sharp scissors, and then in a concentration of 0.05 mol / L Constant current anodizing treatment in HCl solution for 10h, the control current is 0.01mA / cm2. After the anodization is completed, a layer of tan and dense AgCl film is uniformly formed on the surface of the silver wire. After the Ag / AgCl electrode was rinsed with distilled water and dried, the surface was uniformly coated with a layer of nail polish with a thickness of 7 μm. When preparing the reference probe, a 20 μm tip was processed at one end of a Pt-Ir alloy (Pt70%-Ir30%) wire with a length of 70 mm and a diameter of 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com